Multilayered structure with water-impermeable substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

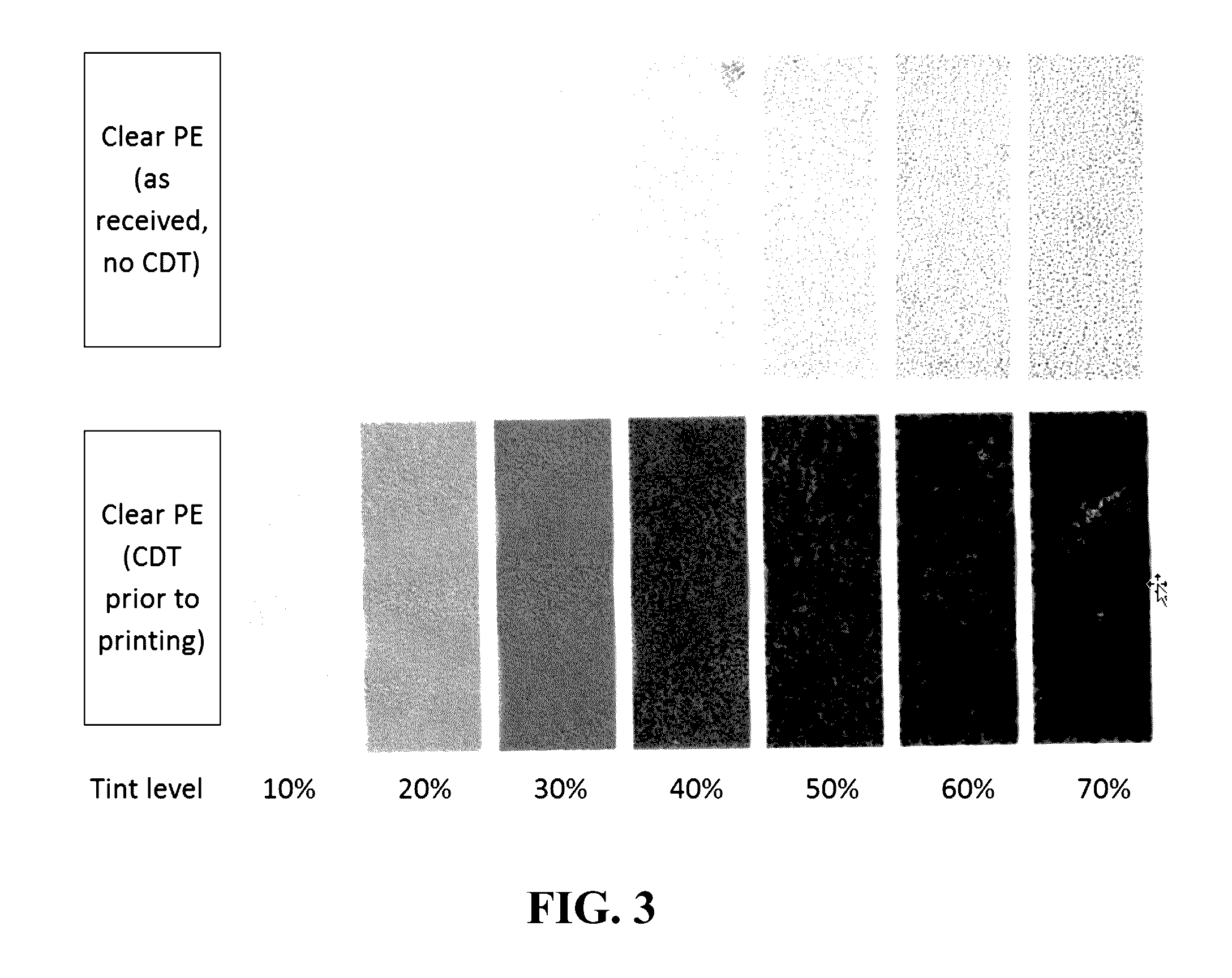

[0084]1. Comparative. A range of commercially available, un-primed impermeable polyolefin film substrates were obtained from several suppliers. The surface energies of these films were estimated by using a set of “dyne pens” (Accudyne Test Marker Pens, Diversified Enterprises, Claremont, N.H.). These films were printed with an anionically stabilized water-based pigment ink (KODAK PROSPER Press packaging black ink) using a KODAK STREAM continuous inkjet printing apparatus. This ink has a static surface tension of 38 dyn / cm, and contains 8.5 wt % glycerol as a co-solvent / humectant. A test image containing patches from 0 to 100% ink coverage in 10% increments was printed (“step wedge”). Another set of these same films were surface treated with a corona discharge treatment apparatus, the surface energies were re-measured, and the films were printed in the same manner. The films were air-dried overnight, but remained slightly tacky for several days. A final dry at 60° C. for 2 hour was d...

##ventive example 3b

Inventive Example 3B

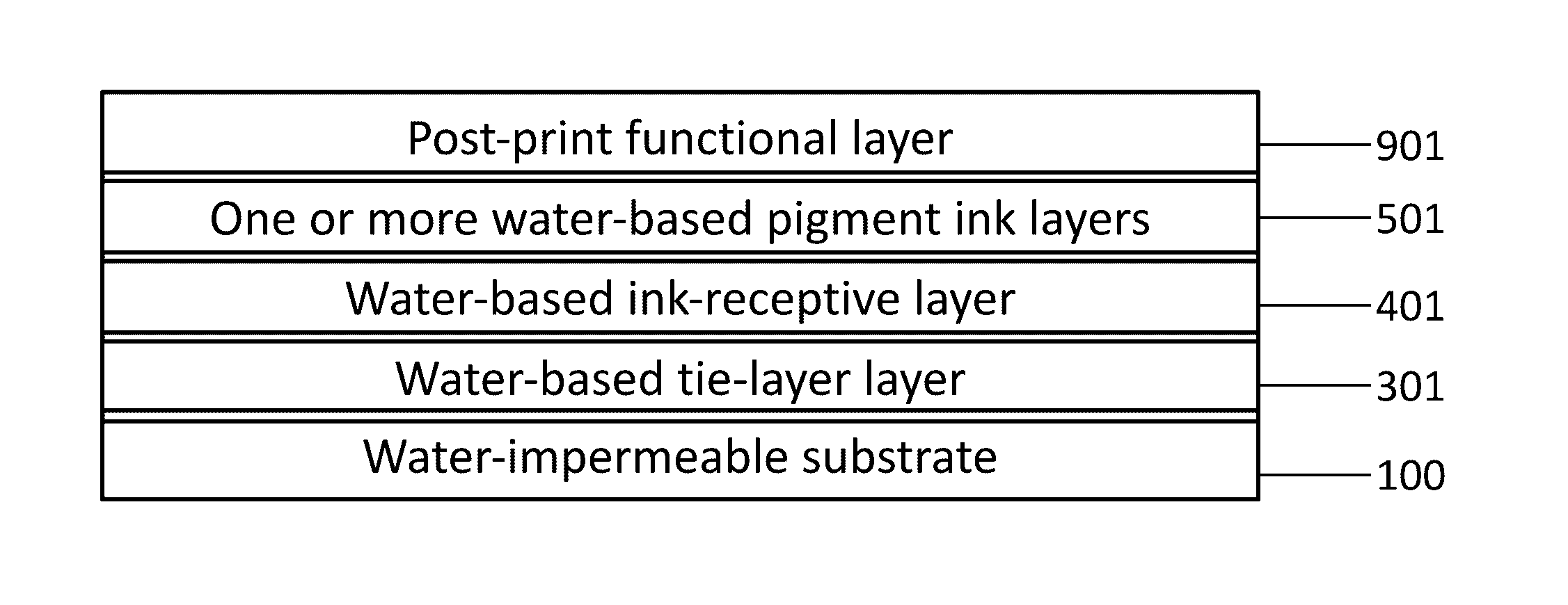

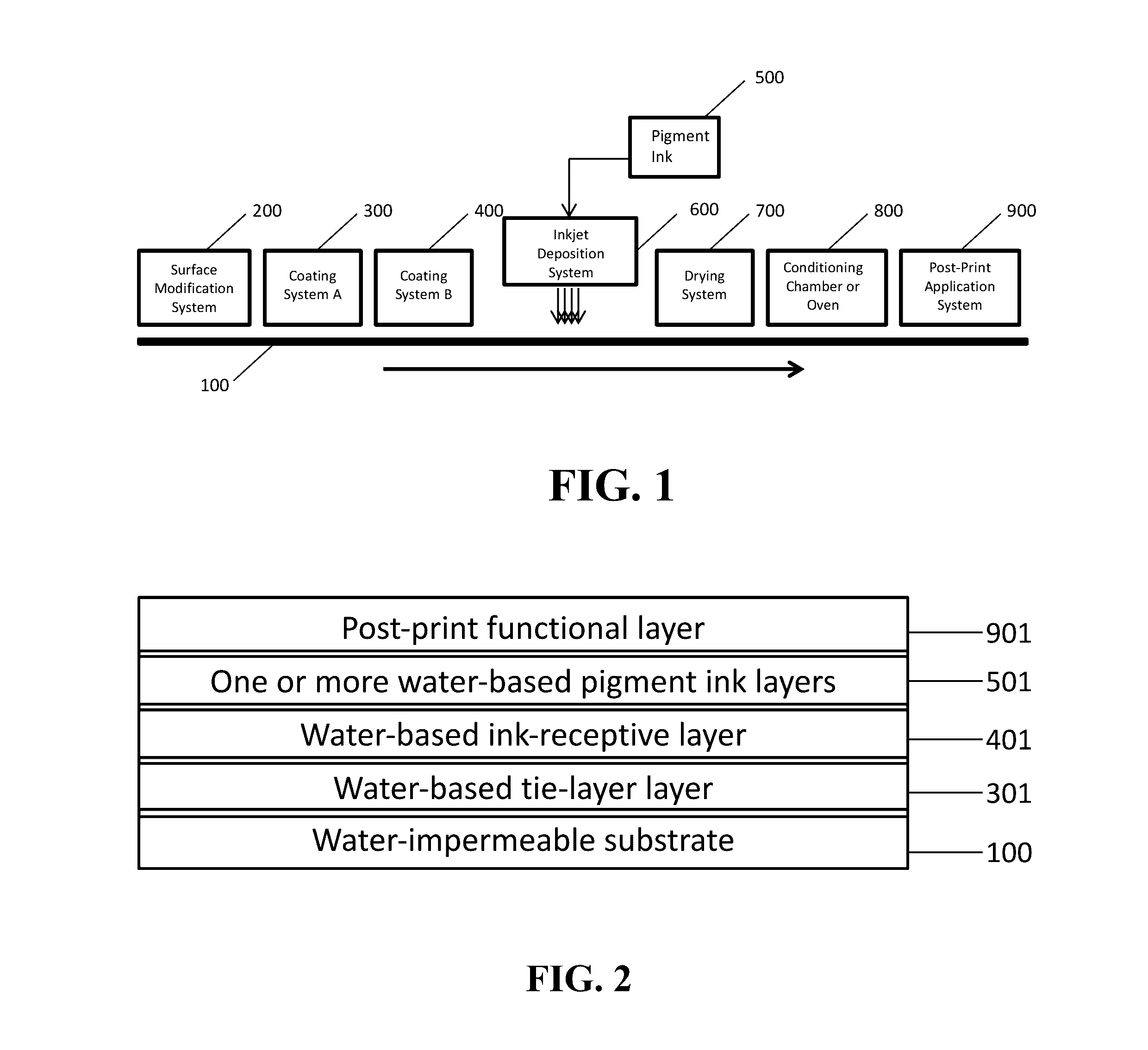

Water-Based Tie-Layer

[0096]The same materials and procedures of Example 3A were used, except for the use of Bicor 84AOH OPP film (ExxonMobil) instead of the plain, uncoated 2-mil OPP film. The Bicor OPP film is 0.84 mil (21 um) thick, and comprises a water-based tie-layer, approximately 0.4-um thick, on one surface. The water-based tie-layer composition further comprises two sub-layers as disclosed in U.S. Pat. No. 5,380,586, with the outermost layer comprising a cross-linked polyvinyl alcohol. The water-based ink-receptive layer described above in Example 3A was coated over this layer and dried. The resulting ink-receptive layer was again smooth and uniform with a similar coat weight as Example 3A.

[0097]The inventive example 3B was printed and tested as described above for Example 3A. The test image was air-dried under ambient conditions for 24 hours and all color patches were found to be dry to the touch. The results are summarized in the following table.

FilmCy...

##ventive example 5b

Inventive Example 5B

Non-Porous Ink-Receptive Layer

[0107]A solution comprising 50 parts acetylacetonate-modified polyvinyl alcohol (Gohsfimer Z320, Nippon Gohsei), 10 parts anhydrous CaCl2 (Dow Chemical), 0.25 parts Cartabond TSI (Clariant), and 1 part Lanco 1799 PTFE wax particles (Lubrizol) was prepared in water containing 10G surfactant (p-isononylphenoxypoly(glycidol)) to yield a solution containing 10% total solids content. This solution was coated using a reverse gravure technique on Bicor 84AOH OPP film (Exxon Mobil) over the side coated with polyvinylalcohol, but used a gravure cylinder with a fluid capacity ˜ 1 / 10th that used for sample 4a. After drying, the resulting coating has a dry coverage of approximately 0.5 g / m2 and is transparent and colorless.

[0108]The comparative and inventive coated films were printed with water-based anionically stabilized pigment ink in the same manner as described in Examples 3A and 3B. The test image containing patches from 0 to 100% ink cove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface energy | aaaaa | aaaaa |

| Surface energy | aaaaa | aaaaa |

| Hydrophilicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com