Concrete taking industrial waste residues as admixture and preparation method thereof

An admixture and concrete technology, applied in the field of building materials, can solve the problems of coagulation affected by setting time, increase of film compactness, and decrease of hydration rate, so as to speed up hydration hardening rate, reduce drying shrinkage, and improve fluidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

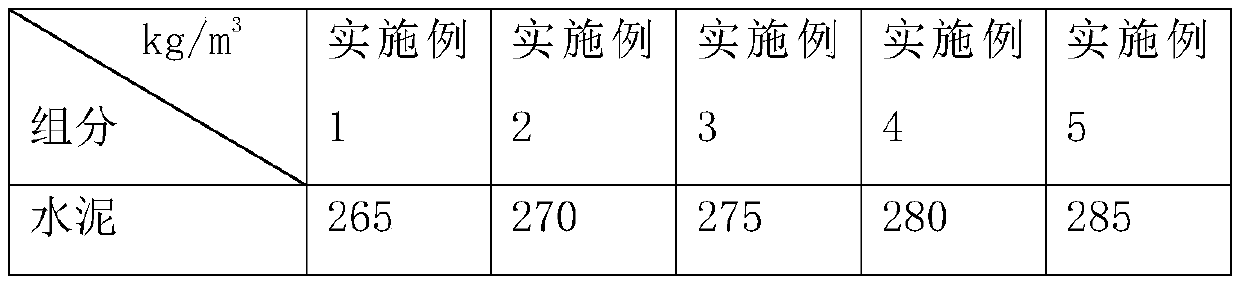

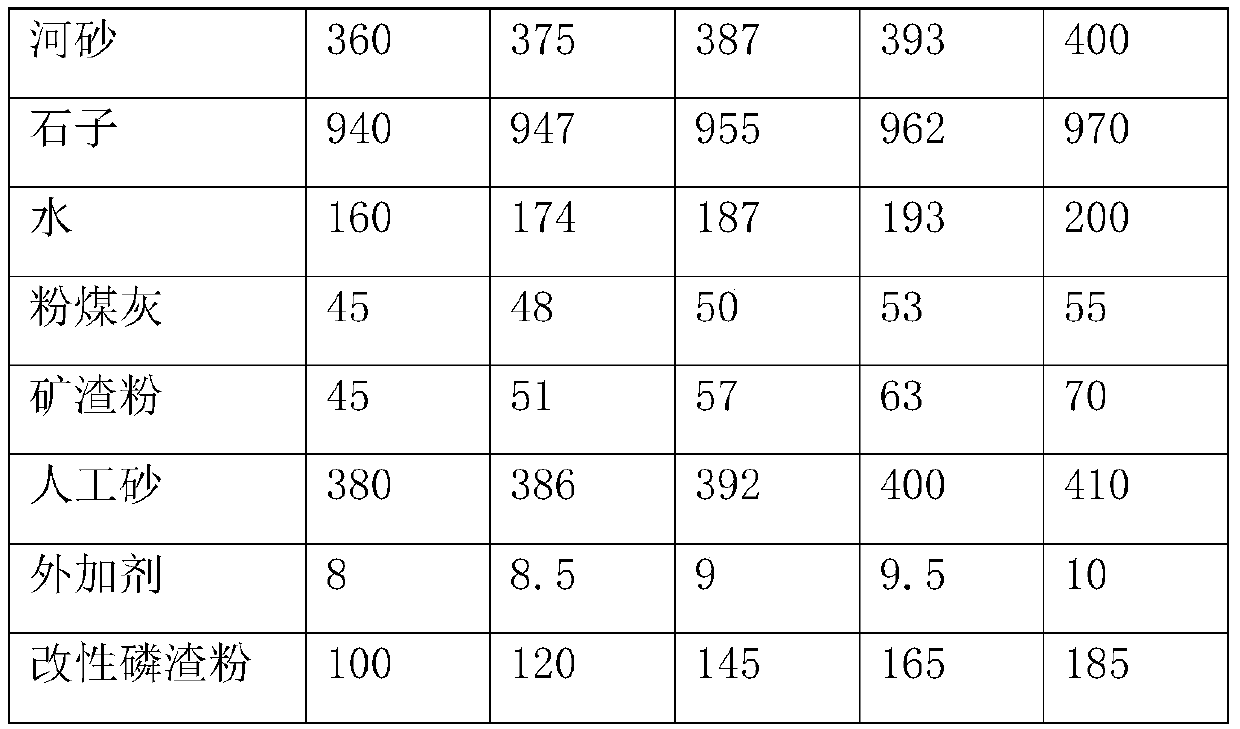

Examples

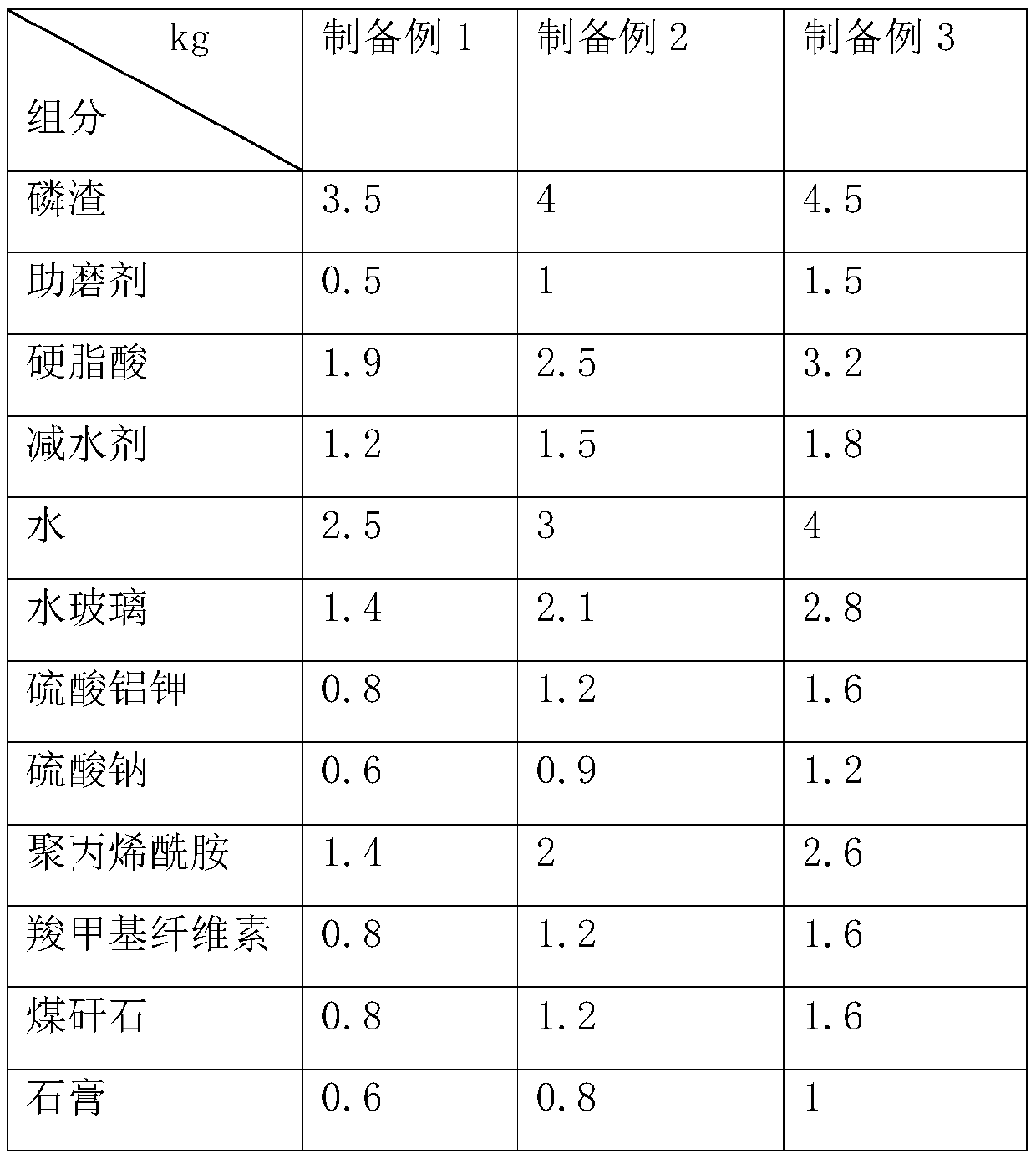

preparation example 1-3

[0038] In Preparation Example 1-3, the sulfamate-based high-efficiency water reducer is selected from the sulfamate-based high-efficiency water reducer sold by Qingdao Hongxia Polymer Material Co., Ltd., and the naphthalene-based high-efficiency water reducer is selected from Linyi Yoshida New Building Materials Co., Ltd. sells the naphthalene-based high-efficiency water reducer with the product number of JT, and the polycarboxylate-based high-efficiency water-reducer is selected from the polycarboxylate-based high-efficiency water-reducer sold by Beijing Tongbanghui Technology Co., Ltd. The molasses is selected from the molasses of the model 65 sold by Jinan Chenglian Chemical Co., Ltd., the polyacrylamide is selected from the polyacrylamide of the model PAM sold by Zhengzhou Zikun Environmental Protection Technology Co., Ltd., and the carboxymethyl cellulose is selected from Dacheng County The carboxymethyl cellulose sold by Xinjie Cellulose Factory is 027, the sodium lignosu...

preparation example 1

[0039] Preparation Example 1: (1) According to the ratio of raw materials in Table 1, dry phosphorus slag at 100° C. for 2 hours to make its water content ≤0.3%; (2) mix 0.5 kg of grinding aid, 1.9 kg of stearic acid 1.2kg of water reducer and 2.5kg of water are mixed, 3.5kg of phosphorus slag, 0.8kg of coal gangue and 0.6kg of gypsum are added, mixed evenly and then ground, the ball-to-material ratio is 18:1, and ground for 120min to make the particle size of the mixed powder The grinding aid is made by mixing triisopropanolamine, triethanolamine and molasses according to the mass ratio of 1:0.2:0.3. The water reducer is sodium lignosulfonate. The chemical composition of phosphorus slag is shown in Table 2 (3) After 1.4kg polyacrylamide, 0.8kg carboxymethyl cellulose and 1.4kg water glass, 0.8kg potassium aluminum sulfate and 0.6kg sodium sulfate are mixed uniformly, add mixed powder, mix and grind, and the obtained particle size is 20μm modified phosphorus slag powder.

[0...

preparation example 2

[0044] Preparation Example 2: (1) According to the raw material ratio in Table 1, dry phosphorus slag at 110° C. for 1.5 h to make its water content ≤0.3%; (2) mix 1 kg of grinding aid, 2.5 kg of stearic acid 1.5kg of water reducing agent mixed with 3kg of water, add 4kg of phosphorus slag, 1.2kg of coal gangue and 0.8kg of gypsum, mix evenly and then grind, the ball-to-material ratio is 19:1, grind for 135min, so that the particle size of the mixed powder is 60μm , the grinding aid is made by mixing triisopropanolamine, triethanolamine and molasses at a mass ratio of 1:0.4:0.5, and the water reducing agent is a sulfamate-based high-efficiency water reducing agent and naphthalene with a mass ratio of 1:1 It is a high-efficiency water reducer, and the chemical composition of phosphorus slag is shown in Table 2; (3) Mix 2kg polyacrylamide, 1.2kg carboxymethyl cellulose with 2.1kg water glass, 1.2kg aluminum potassium sulfate and 0.9kg sodium sulfate After uniformity, the mixed p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com