Method for producing walling material by using papermaking white mud

A technology for paper-making lime mud and wall materials, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of clogging equipment, high production costs, threatening food production, etc., and reduce production energy consumption. and cost, low cost of industrialized operation, and the effect of promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

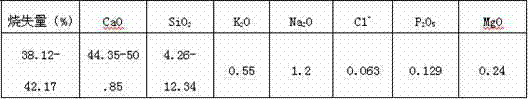

[0036] A method for producing wall materials using papermaking white mud, comprising the following steps:

[0037] 1) By weight percentage, take 43.5% of white mud, 45% of lithium slag, 10% of PO42.5 cement, and 1.5% of active stimulating agent (RDDM). Add to the mixer and mix for 3 minutes, then pour into the mold, and vibrate 120 times on the vibrating table to form;

[0038] 2) Put the mold in a curing box with a temperature of 20±1°C and a humidity of 91% for 20 hours, then remove the mold, and then put it in a curing box with a temperature of 65°C for 20 hours to obtain the wall material.

Embodiment 2

[0040] A method for producing wall materials using papermaking white mud, comprising the following steps:

[0041] 1) In terms of percentage by weight, take 48.9% of white mud, 30% of lithium slag, 20% of PO42.5 cement, and 1.1% of active activator (RDDM), mix it in a mixer for 5 minutes, then pour it into the mold, and 80 vibrations on the vibrating table for forming;

[0042] 2) Put the mold in a curing box with a temperature of 20±1°C and a humidity of 92% for 24 hours, then remove the mold, and then put it in a curing box with a temperature of 65°C for 30 hours to obtain the wall material.

Embodiment 3

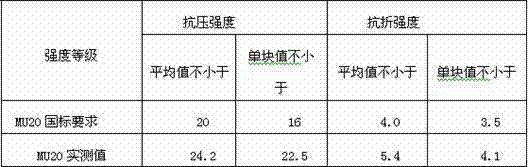

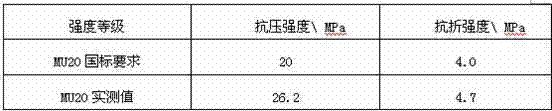

[0044] A kind of method utilizing white mud to produce wall body material is characterized in that: it comprises:

[0045] 1) By weight percentage, take 58.2% of white mud, 20% of lithium slag, 20% of PO42.5 cement, 1.8% of active stimulating agent (RDDM), mix in a mixer for 10 minutes, then pour into the mold, and 60 vibrations on the vibrating table for forming;

[0046] 2) Put the mold in a curing box with a temperature of 20±1°C and a humidity of 95% for 30 hours, then remove the mold, and then put it in a curing box with a temperature of 65°C for 24 hours to obtain the wall material.

[0047] The wall body brick that the wall body material that this example is made is made by autoclave method, through measuring, the mechanical property of excellent product is as follows:

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com