Modified petroleum coke granule composite profile control water blocking agent and multi-round bidirectional blocking control technology

A technology of profile control and water plugging agent and glue particles, which can be used in drilling compositions, production fluids, wellbore/well components, etc., and can solve the problems of erosion resistance, poor shear resistance, and low strength, etc. Achieve excellent stability, good flow viscoelasticity, and prolong the success rate of profile control and water plugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

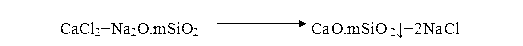

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Preparation and Trial of Modified Petroleum Rubber Particle Composite Profile Control and Water Plugging Agent

[0047] Agent A: Add water to polyacrylamide with a molecular weight of 20 million to prepare a polyacrylamide solution with a concentration of 0.1% (weight); the parts by weight of each component are: polyacrylamide solution 100, modulus 3.1 concentration, density 40 % (weight) sodium silicate aqueous solution 1.25, potassium aluminum sulfate 0.2, hydrochloric acid 1 with a concentration of 30% (weight), calcium chloride 0.5; in the polyacrylamide solution, add sodium silicate aqueous solution, sulfuric acid in turn under normal temperature stirring Potassium aluminum, hydrochloric acid, and calcium chloride are stirred evenly to form a solution of agent A with a concentration of 0.1% by weight (calculated as polyacrylamide) for future use.

[0048] Agent B: Add water to polyacrylamide with a molecular weight of 12 million to prepare a polyacrylami...

Embodiment 2

[0062] Example 2: Preparation and Trial of Modified Petroleum Rubber Particle Composite Profile Control and Water Plugging Agent

[0063]Agent A: The molecular weight of polyacrylamide is 12 million, the concentration of polyacrylamide solution is 0.3% (weight); the parts by weight of each component are: polyacrylamide solution 100, the modulus is 3.4, and the concentration is 40% (weight). Sodium acid aqueous solution 2.5, potassium aluminum sulfate 0.2, hydrochloric acid 2 with a concentration of 30% (weight), calcium chloride 0.5, forming a solution of agent A with a weight percentage concentration of 0.3% (calculated by polyacrylamide) for subsequent use, and others are the same as in the embodiment 1.

[0064] Agent B: The molecular weight of polyacrylamide is 20 million, the concentration of polyacrylamide solution is 0.3% (weight); the parts by weight of each component are: polyacrylamide solution 100, particle size 50 (μm) modified petroleum coke particles 10. Stearic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com