Method for preparing water-based penetration type concrete protective agent

A concrete and permeable technology, which is applied in the field of cement mortar and cement concrete waterproof protection materials, can solve the problems that do not involve the composition of aluminum potassium sulfate dodecahydrate, etc., and achieve the effect of improving impermeability, improving durability and strengthening concrete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

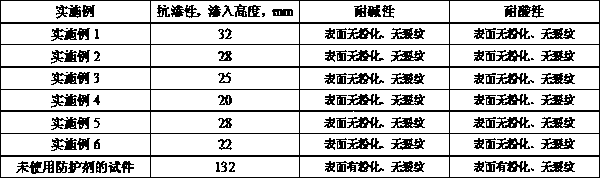

Examples

Embodiment 1

[0023] Water-based permeable concrete protective agent is made of the following raw materials in mass percentage:

[0024] Potassium aluminum sulfate dodecahydrate 0.4%, sodium hydroxide 2%, citric acid (anhydrous citric acid) 0.015%, silane coupling agent isobutyltriethoxysilane 2%, sodium silicate aqueous solution (Baumé 40 ~42) 22%, deionized water (resistivity greater than or equal to 10 megohm·cm) 73.585%.

[0025] The specific preparation steps are as follows: under the condition of stirring at a rotating speed of 100r / min, add potassium aluminum sulfate dodecahydrate into deionized water, and stir for 10min; then add sodium hydroxide, and stir for 15min; at a rotating speed of 200r / min, Add citric acid and stir for 15 minutes; at a speed of 50 r / min, add sodium silicate aqueous solution and silane coupling agent in turn, and stir for 20 minutes to obtain a mixed solution; let stand for 2 hours to obtain a water-based penetrating concrete protective agent.

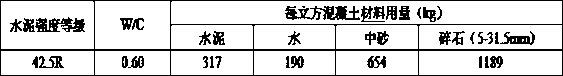

[0026] Conc...

Embodiment 2

[0028] Water-based permeable concrete protective agent, its components and mass percentages are:

[0029] Potassium aluminum sulfate dodecahydrate 0.4%, sodium hydroxide 2%, citric acid (anhydrous citric acid) 0.015%, silane coupling agent isobutyltriethoxysilane 2%, sodium silicate aqueous solution (Baumé 40 ~42) 22%, deionized water (resistivity greater than or equal to 10 megohm·cm) 73.585%.

[0030] The preparation method is the same as in Example 1.

[0031] Concrete specimen surface spraying dosage: 0.3kg / m 2 .

Embodiment 3

[0033] Water-based permeable concrete protective agent, its components and mass percentages are:

[0034] Potassium aluminum sulfate dodecahydrate 0.6%, sodium hydroxide 4%, citric acid (anhydrous citric acid) 0.025%, silane coupling agent isobutyltriethoxysilane 4%, sodium silicate aqueous solution (Baumé 40 ~42) 25%, deionized water (resistivity greater than or equal to 10 megohm·cm) 66.375%.

[0035] The preparation method is the same as in Example 1.

[0036] Concrete specimen surface spraying dosage: 0.2kg / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com