Positive electrode sulfur-carrying material of lithium-sulfur battery and preparation method of lithium-sulfur battery

A lithium-sulfur battery and positive electrode material technology, which is applied in the direction of battery electrodes, electrolyte storage battery manufacturing, secondary batteries, etc., can solve the problems of poor electrolyte absorption capacity, capacity loss, unfavorable high-current charging and discharging of Nafion membrane, etc., and achieve high efficiency. Increased rate charge and discharge cycle life, speed capacity and performance stability, and the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Preparation of Nano Lithium Cobalt Oxide

[0043] Weigh lithium hydroxide monohydrate (2.4g) and cobalt nitrate hexahydrate (29.1g) according to the mass ratio of 24:291 and dissolve them in 100ml of deionized water, add 10g of polyethylene glycol (PEG) with a molecular weight of 10000g / mol, and stir After dissolving, it was spray-dried, calcined at 700° C. for 4 hours, and ball milled for 2 hours to obtain nano-lithium cobaltate. The ball milling speed was 1000 rpm.

Embodiment 2

[0044] Example 2: Preparation of Nanoscale Lithium Cobaltate Modified Sulfur-Containing Macroporous Carbon Material

[0045] Add sucrose and thiourea to deionized water, and mix uniformly to form a solution; wherein the molar ratio of sucrose and thiourea is 1:1, and the molar ratio of thiourea to water is 1:10,

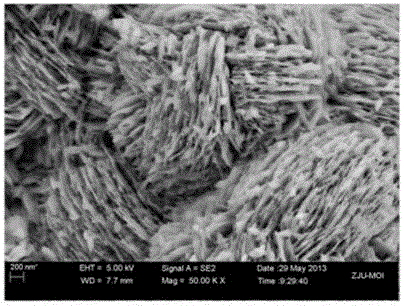

[0046] Polymerize the solution at 90°C for 30 minutes to form a thiourea-sucrose resin, and add hydrophilic nano-CaCO with a particle size of 15-40nm 3 (produced by Ruicheng Warner Nano Materials Co., Ltd.) and the nano-lithium cobaltate prepared in Example 1 form a suspension after stirring; wherein the mass ratio of thiourea-sucrose resin, calcium carbonate and lithium cobaltate is 1: 1:0.1; after the suspension was spray-dried, in flowing N 2 Put it in a tube furnace under protection, heat at 200°C and 700°C for 2 hours and 4 hours respectively, wash the carbonized product with 5wt% hydrochloric acid and deionized water successively, and dry at a constant tempera...

Embodiment 3

[0047] Example Three: Preparation of Positive Electrode Material

[0048] Add water-soluble starch and thiourea to deionized water, and mix uniformly to form a solution; wherein, the molar ratio of water-soluble starch to thiourea is 1:1, and the molar ratio of thiourea to water is 1:10,

[0049] Polymerize the solution at 90°C for 30 minutes to form thiourea-starch resin, add hydrophilic nano-CaCO with a particle size of 15-40nm 3 (produced by Ruicheng Warner Nano Materials Co., Ltd.) and the nano-lithium cobaltate prepared in Example 1 form a suspension after stirring; wherein the mass ratio of thiourea-starch resin, calcium carbonate and lithium cobaltate is 1: 1:0.3; after the suspension was spray-dried, in flowing N 2 Put it in a tube furnace under protection, heat at 200°C and 700°C for 2 hours and 4 hours respectively, wash the carbonized product with 5wt% hydrochloric acid and deionized water successively, and dry at a constant temperature at 120°C for 4 hours to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com