Method for preparing compound electrical contact material

An electrical contact material and electrical contact technology, applied in contact materials, circuits, electrical switches, etc., can solve the problems of unclear influence of the growth of CNTs arrays on the specific action mechanism of conductive substrates and catalysts, complicated processes, etc. Mechanical abrasion resistance and welding resistance, improved conductivity, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

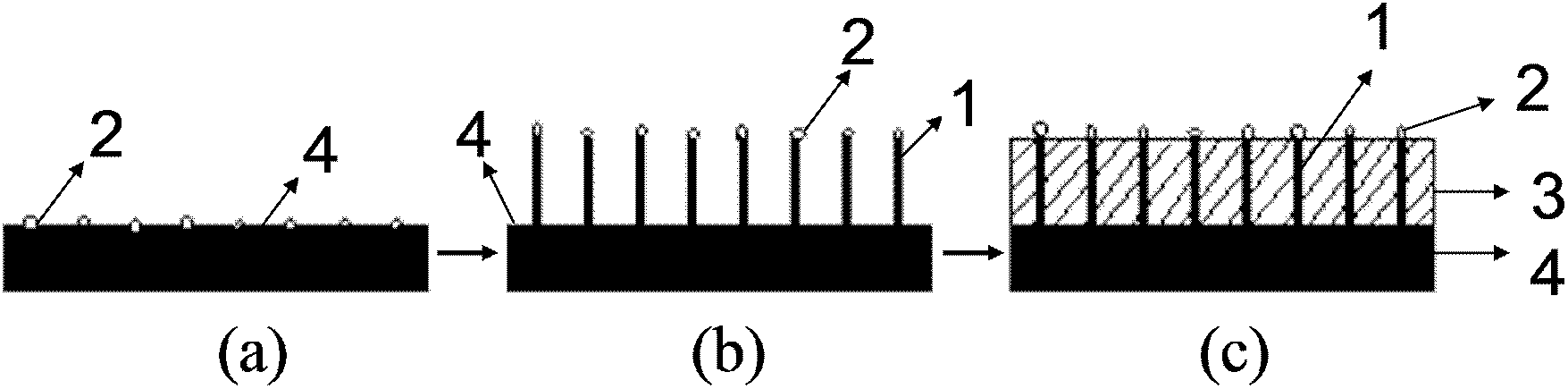

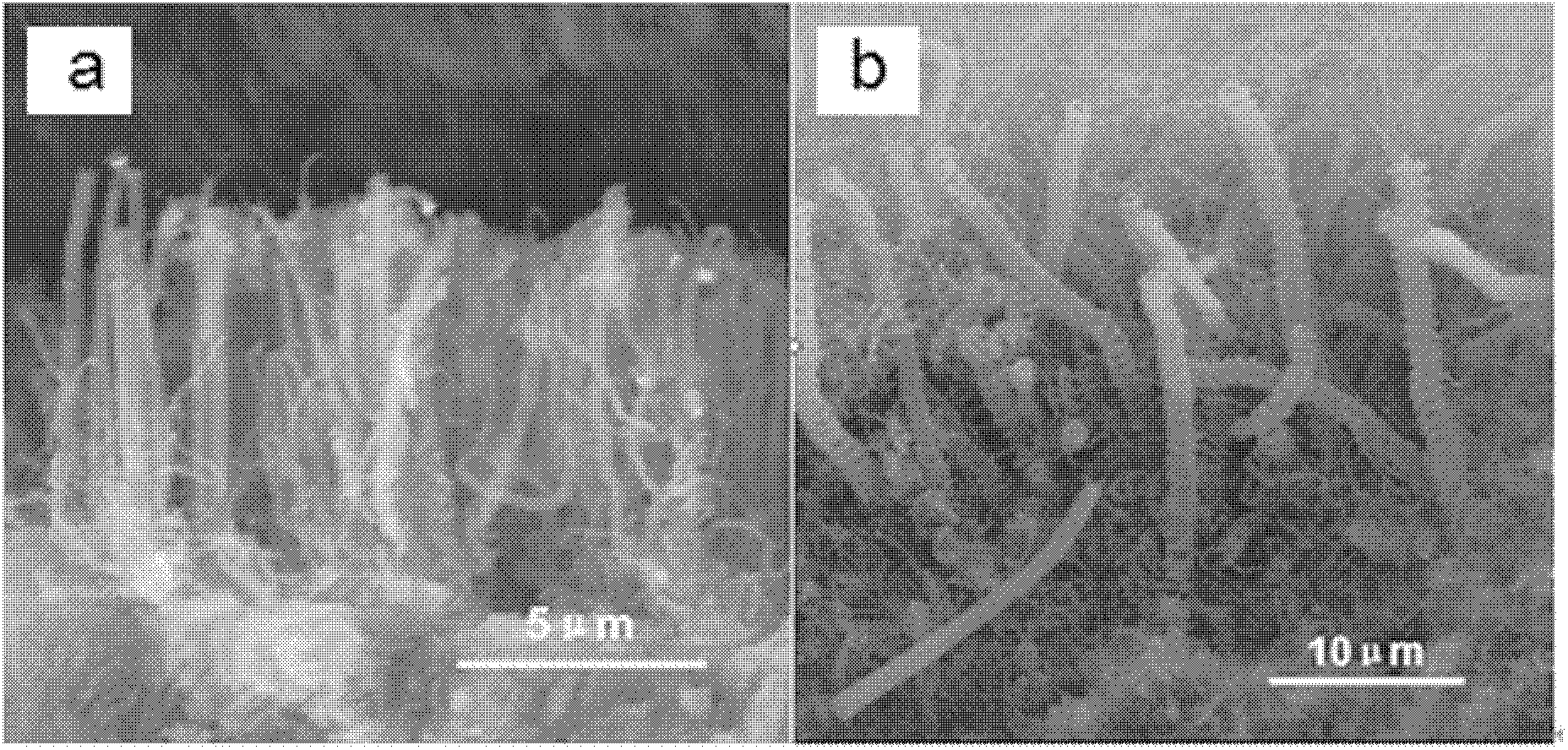

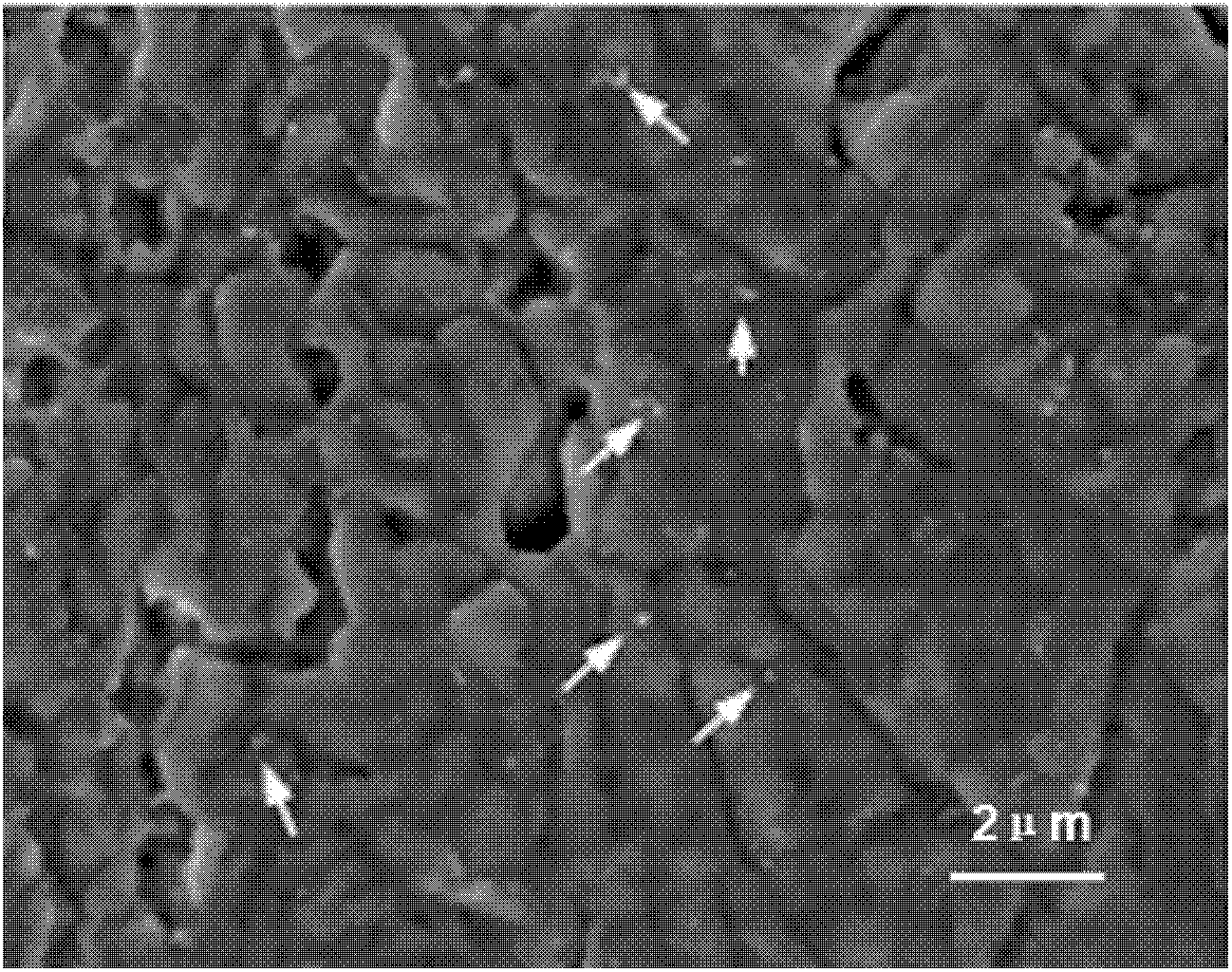

[0018] The preparation method (abbreviation preparation method of the composite electrical contact material of the present invention's design, see Figure 1-3 ), simply speaking, through the preparation of a new composite catalyst and precise control of the experimental process, the chemical vapor deposition technology is used to directly grow the CNTs array on the surface of the copper substrate, and then the Ag is filled into the CNTs array by impregnation, sintering and other techniques to obtain aligned CNTs. - Novel composite electrical contact material with Ag composite cladding. Its specific process is:

[0019] 1) Preparation of catalyst precursor

[0020] Embodiment Take a sample copper sheet with a diameter of 12mm and a thickness of 3mm, first use a mechanical method to polish the sample copper sheet, and then perform ultrasonic cleaning on the sample copper sheet after polishing in distilled water-acetone-alcohol, and after drying, perform plasma treatment or micr...

Embodiment 1

[0029] Mechanically polish a copper sheet with a diameter of 12mm and a thickness of 3mm. After polishing, place the copper sheet in 50ml of distilled aqueous solution for ultrasonic cleaning for 10 minutes, and then place it in 50ml of acetone solution and alcohol solution for 10 minutes. After cleaning, the copper sheet was blown dry at room temperature, and then subjected to argon plasma treatment for 0.5 min after drying. Then configure a mixed aqueous solution of nickel nitrate hexahydrate and yttrium nitrate hexahydrate as a catalyst solution, wherein the concentration of nickel nitrate is 0.0001 mol / L, and the mass ratio of nickel and yttrium Ni:Y is 1:1. Then impregnate a layer of Ni / Y catalyst solution with a concentration of 0.0001mol / L on the copper sheet treated with argon plasma, and then put the copper sheet into a vacuum drying oven and dry it under vacuum at 80°C for 1 hour to obtain Ni / Y / Cu Catalyst precursor; then the obtained Ni / Y / Cu catalyst precursor is pu...

Embodiment 2

[0031] A copper sheet with a diameter of 12 mm and a thickness of 3 mm was mechanically polished, cleaned and dried as in Example 1, and then plasma treated for 1 min. Then configure a mixed aqueous solution of nickel nitrate hexahydrate and yttrium nitrate hexahydrate as a catalyst solution, wherein the concentration of nickel nitrate is 0.02 mol / L, and the mass ratio of nickel and yttrium Ni:Y is 2:1. Then impregnate a layer of 0.02mol / L Ni / Y catalyst solution on the plasma-treated copper sheet, then put the copper sheet into a vacuum drying oven and dry it under vacuum at 100°C for 1 hour to obtain a Ni / Y / Cu catalyst precursor . Then the obtained Ni / Y / Cu catalyst precursor is put into a quartz boat, and the quartz boat is placed in the constant temperature zone in the middle of the reaction tube; Calcination for 1 hour, then the temperature was raised to 750°C, and acetylene and hydrogen (argon, hydrogen, acetylene gas flow ratio Ar:H 2 : C 2 h 2 CNTs were grown at 150s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com