Precision control device of vacuum laser welding machine for preparing sodium-sulfur batteries

A laser welding machine and sodium-sulfur battery technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of small spot size, narrow welding seam, welding defects, etc., and achieve the effect of ensuring welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

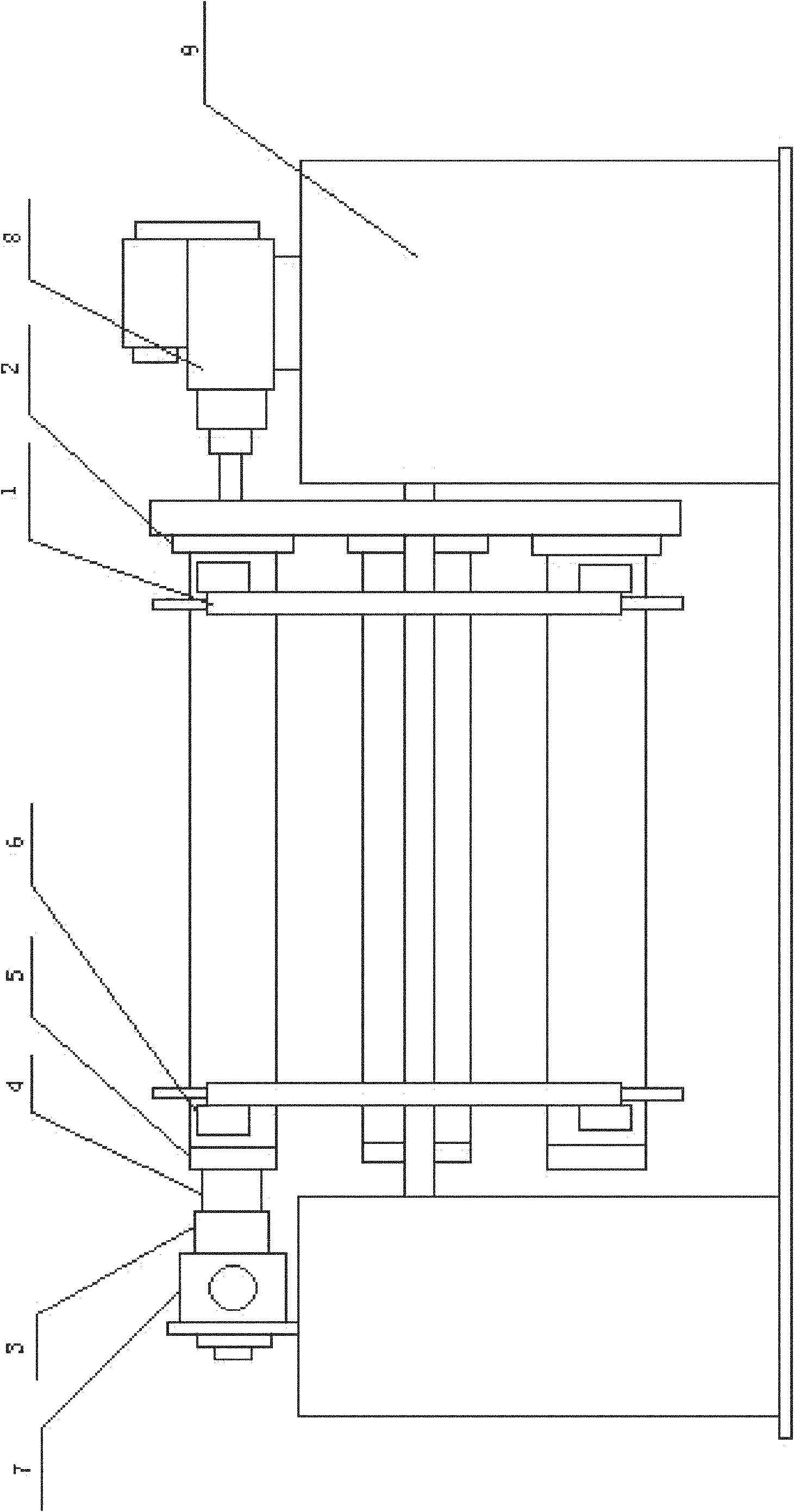

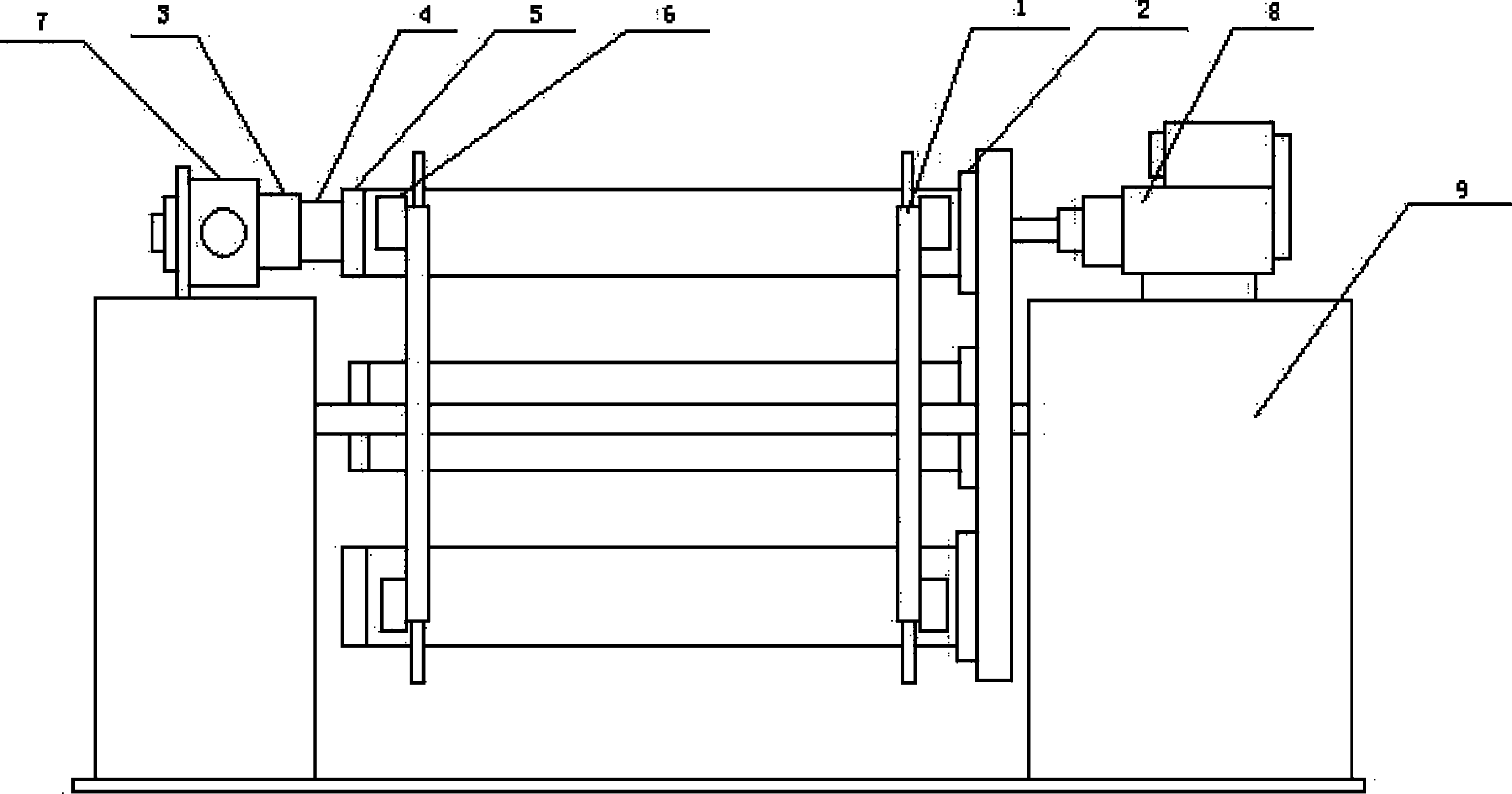

[0019] figure 1 The structure of an embodiment of the vacuum laser welding machine precision control device for sodium-sulfur battery preparation of the present invention is shown. See figure 1 , the control device of this embodiment has a rotating bracket 1, a positioning sleeve 2, a coupling transmission mechanism 3, a turning block 4, a fixed sleeve 5, a hinge locking mechanism 6, a rotary mechanism 7, an ejection mechanism 8 and a control transmission mechanism 9 Assemblies, put n batteries in sequence in the battery cavity in the vacuum box with a vacuum degree of less than 10Pa, open the bayonet pin on the rotating bracket 1, open the pressing block linked by the hinge locking mechanism 6, and first put the battery Put the end cap into the opening of the positioning sleeve 2 on the right side, and the positioning sleeve 2 precisely fixes the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com