Electrolyte solution for lithium-sulfur battery

A lithium-sulfur battery and electrolyte technology, applied in the field of new energy, can solve problems such as insufficient improvement of battery performance, achieve the effects of increasing capacity, inhibiting corrosion and structural damage, and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

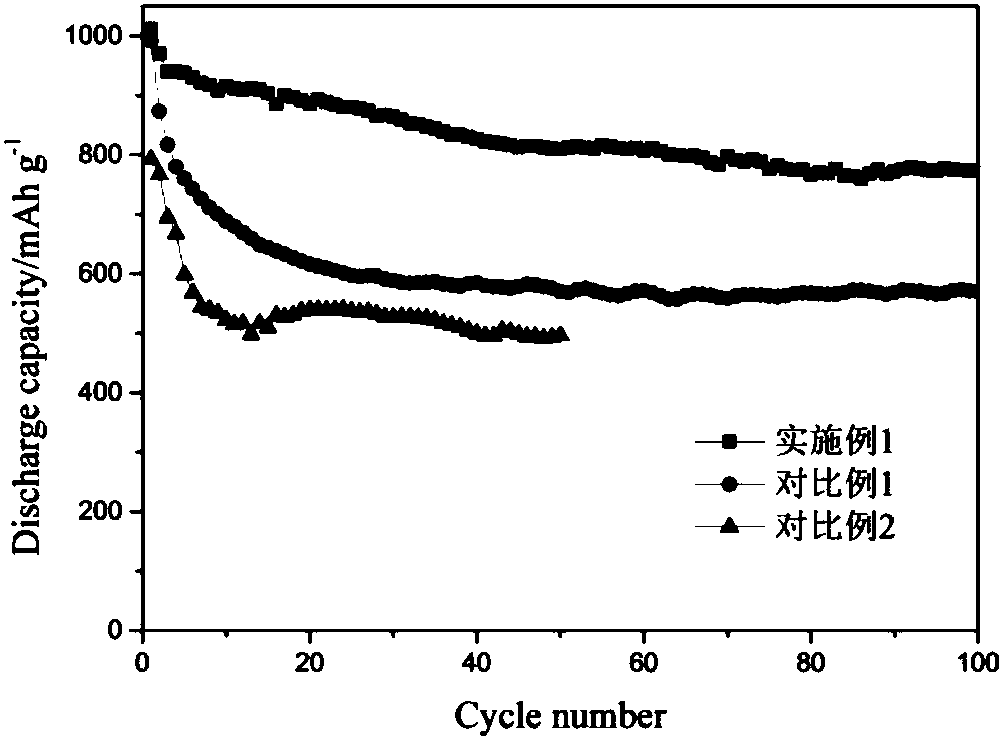

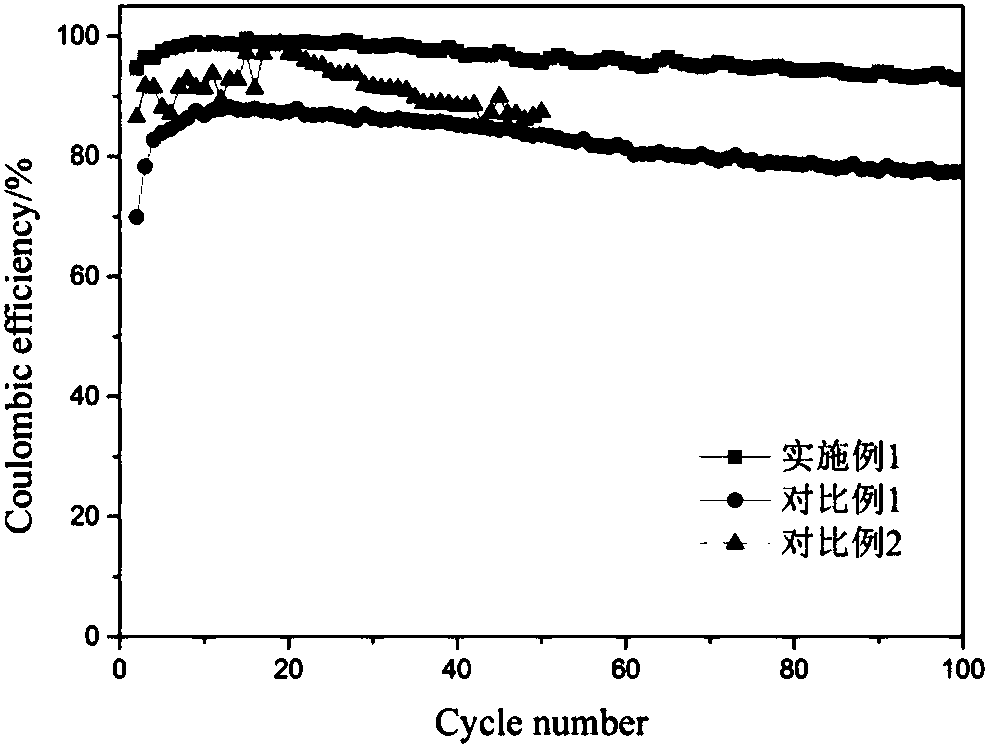

Examples

Embodiment 1

[0024] After grinding and mixing 75wt% sublimated sulfur and 25wt% nano-carbon black, they were treated in a tube furnace at 150°C for 12h, followed by holding at 250°C for 2h, and then cooled naturally to obtain a sulfur / carbon composite material.

[0025] The above composite material, nano-carbon black and polyvinylidene fluoride are fully mixed in N-methylpyrrolidone at a mass ratio of 8:1:1, coated evenly on aluminum foil, dried in vacuum at 60°C, and punched into sheets.

[0026] In a glove box filled with argon, the above-mentioned sulfur electrode, polyolefin separator and metal lithium sheet were stacked in a sandwich form, and the electrolyte was added dropwise to assemble a CR2025 button battery.

[0027] Electrolyte composition: 1mol / L LiTFSI and 0.1mol / L LiFSI are fully dissolved in PYR 14 In the TFSI, 1,1,2,2-tetrafluoroethyl-2,2,2-trifluoroethyl ether (TFTFE) is further added to obtain an electrolyte solution, wherein the volume ratio of TFTFE in the electrolyte ...

Embodiment 2

[0029] The preparation of the sulfur-carbon composite material, the manufacture of the sulfur electrode and the assembly of the button battery are the same as in Example 1.

[0030] Electrolyte composition: 0.5mol / L LiClO 4 and 0.3mol / L LiNO 3 Fully soluble in P 13 In the BETA, 1,1,2,2-tetrafluoroethyl ethyl ether (ETFE) was further added to prepare the electrolyte solution, wherein the volume ratio of ETFE in the electrolyte solution was 15%.

Embodiment 3

[0032] The preparation of the sulfur-carbon composite material, the manufacture of the sulfur electrode and the assembly of the button battery are the same as in Example 1.

[0033] Electrolyte composition: 2mol / L LiCF 3 SO 3 Fully soluble in P 1,2O1 In TFSI, then further add 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether (TTE) to prepare the electrolyte, wherein the volume ratio of TTE in the electrolyte is 85% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com