Sodium-sulfur battery and manufacture method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

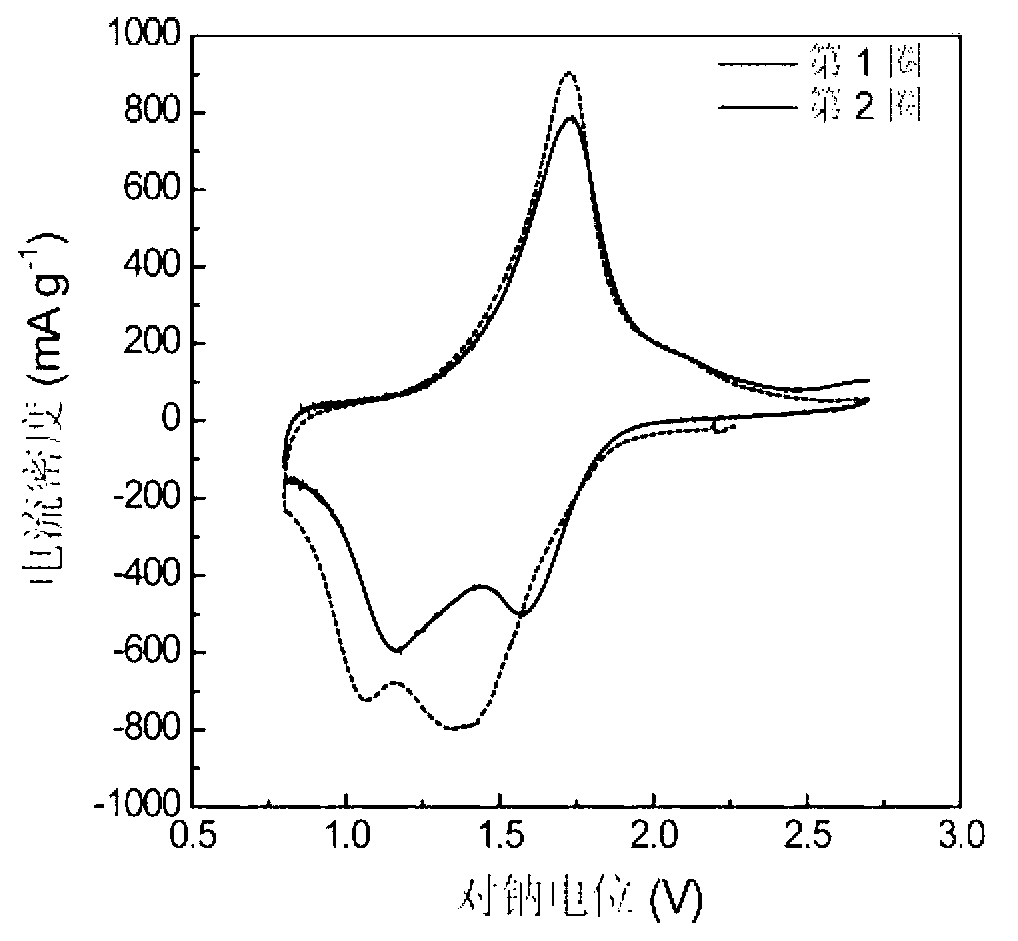

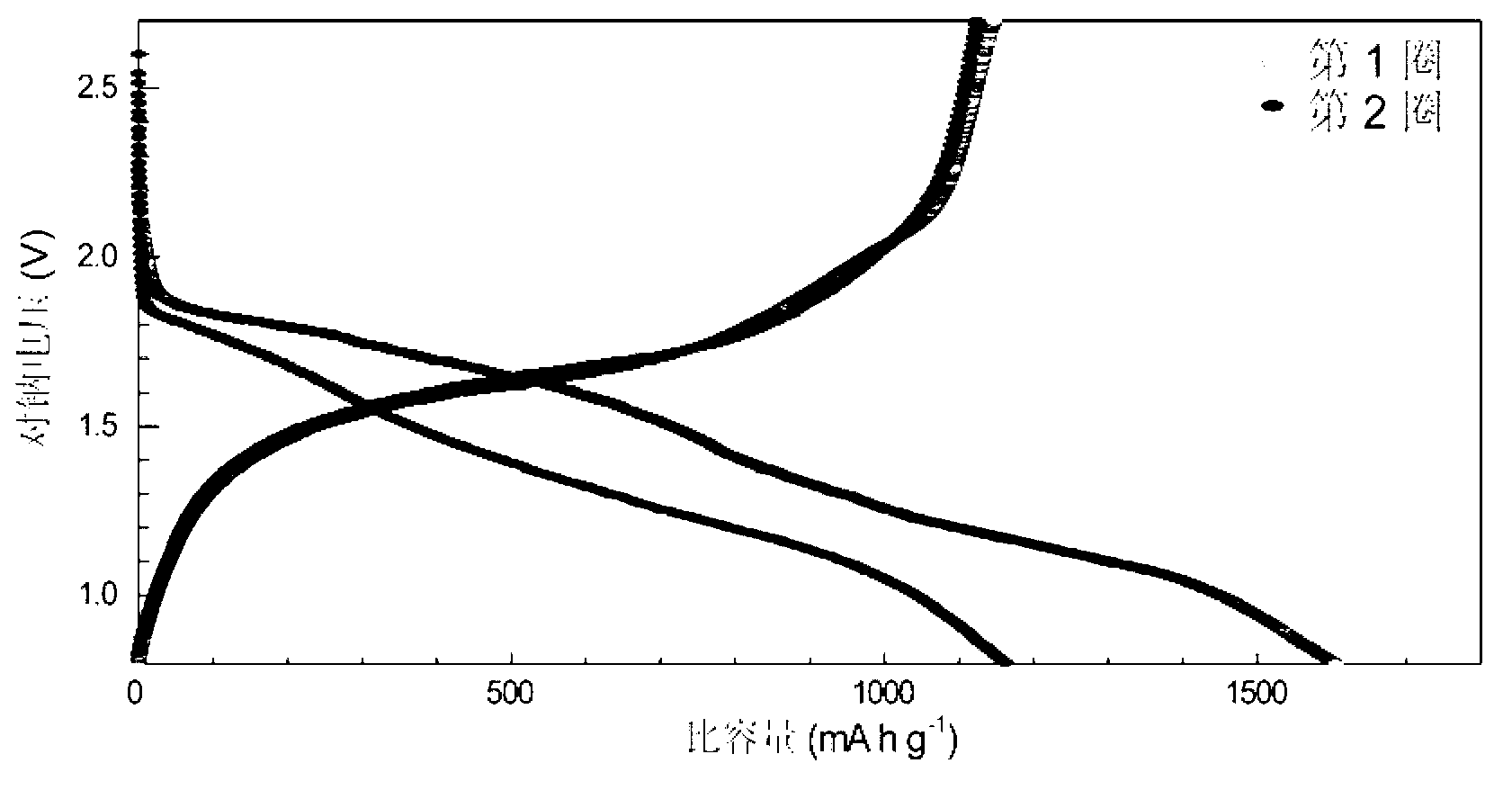

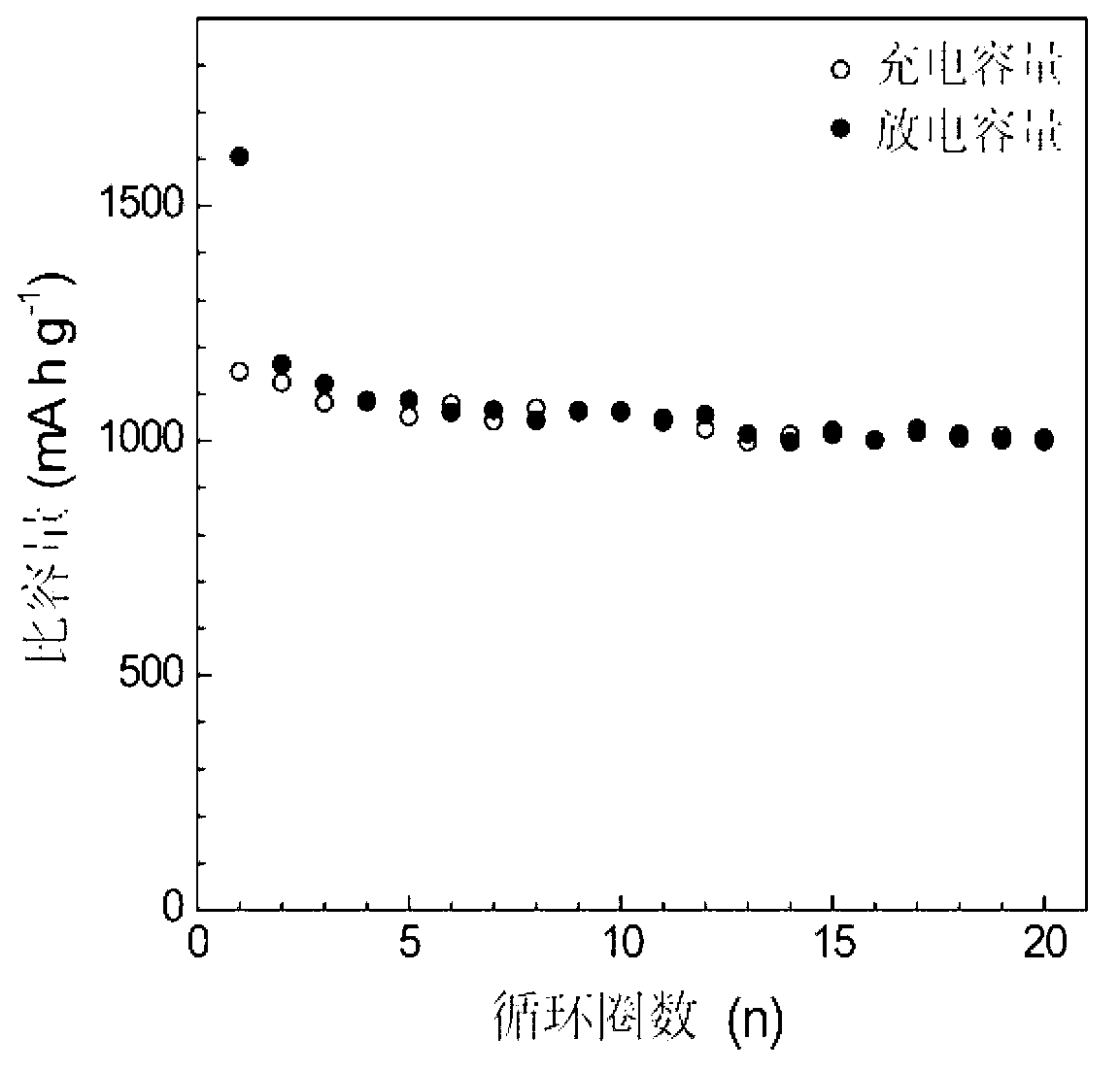

Method used

Image

Examples

Embodiment 1

[0035] (1) Preparation of sulfur-microporous support composite positive electrode

[0036] The microporous carrier used in the experiment is microporous carbon (purchased from Japan Kuraray Co.), with a specific surface area of 920m 2 g -1 , the pore volume is 0.50cm 3 g -1 , the average pore size is 0.6nm, and the mass fraction of sulfur in the prepared sulfur-microporous carbon composite is 50%.

[0037] The preparation method of sulfur-microporous carbon composite is as follows:

[0038] (1) Weigh sulfur and microporous carbon according to the mass ratio of 1:1 and mix them evenly;

[0039] (2) The mixture of sulfur and microporous carbon was heated at 1°C min -1 The heating rate is heated to 130 ° C and maintained for 15 hours, so that the sulfur is fully dispersed in the microporous carbon;

[0040] (3) Stop heating and return to room temperature to obtain sulfur-microporous carbon composite.

[0041] The sulfur-microporous carbon composite prepared above is mixe...

Embodiment 2

[0047] (1) Preparation of sulfur-microporous support composite positive electrode

[0048] The microporous carrier used in the experiment is microporous iron oxide (purchased from Sigma-Aldrich Company), with a specific surface area of 340 m 2 g -1 , the pore volume is 0.22cm 3 g -1 , the average pore size is 1.5nm, and the mass fraction of sulfur in the prepared sulfur-microporous iron oxide composite is 20%.

[0049] The preparation method of sulfur-microporous iron oxide composite is as follows:

[0050] (1) Weigh sulfur and microporous iron oxide according to the mass ratio of 1:4 and mix them evenly;

[0051] (2) The mixture of sulfur and microporous iron oxide was heated at 3°C min -1 Heating rate to 150°C and maintaining heating for 10h, so that sulfur can be fully dispersed in the microporous iron oxide;

[0052] (3) Stop heating and return to room temperature to obtain sulfur-microporous iron oxide composite.

[0053] The sulfur-microporous iron oxide compo...

Embodiment 3

[0059] (1) Preparation of sulfur-microporous support composite positive electrode

[0060] The microporous carrier used in the experiment is a microporous metal-organic framework coordination polymer (MIL-100(Cr), which is a coordination polymer formed by chromium and trimesic acid, purchased from Materiaux Institut Lavoisier Company), and the specific surface area 4000m 2 g -1 , the pore volume is 2cm 3 g -1 , the average pore diameter is 1.2nm, and the mass fraction of sulfur in the prepared sulfur-microporous metal-organic framework composite is 80%.

[0061] The preparation method of sulfur-microporous metal-organic framework composite is as follows:

[0062] (1) Weigh the sulfur and the microporous metal-organic framework according to the mass ratio of 4:1 and mix them uniformly;

[0063] (2) The mixture of sulfur and microporous MOFs was heated at 5°C min -1 The heating rate is heated to 165 ° C and maintained for 5 hours, so that the sulfur is fully dispersed in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com