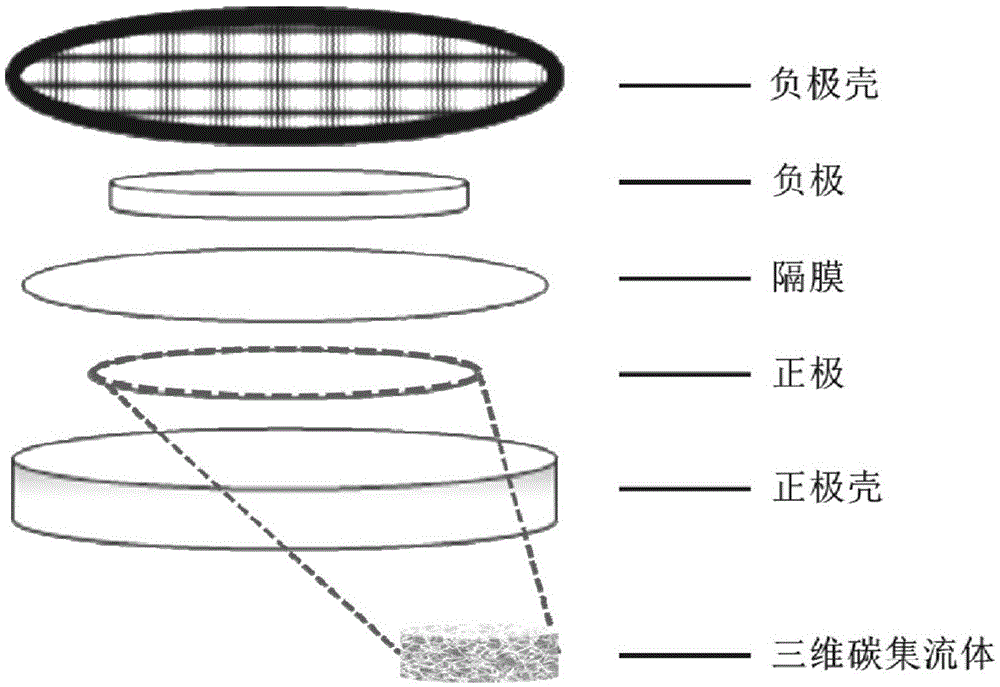

Preparation method and application of lithium-sulfur battery three-dimensional carbon current collector

A lithium-sulfur battery and current collector technology, applied in the field of electrochemical batteries, to achieve the effects of improving cycle stability, inhibiting migration, and having good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation method of the lithium-sulfur battery three-dimensional carbon current collector of this embodiment includes the steps of: soaking the organic foam material polyurethane foam material in organic solvent ethylene glycol for 6 hours, then ultrasonically treating it for 0.5 hour, washing it with distilled water for 3 times, and placing it in a vacuum In a drying oven, dry at 60°C for 12 hours to obtain a carbon precursor. Under the protection of nitrogen atmosphere, the carbon precursor was heated up to 800°C at a heating rate of 5°C / min, kept for 2 hours, and cooled to room temperature naturally. After taking it out, it was cut to a suitable size with a cutting machine to obtain an elastic lithium-sulfur battery. Three-dimensional carbon current collector. The compressibility of the above polyurethane foam was 60%.

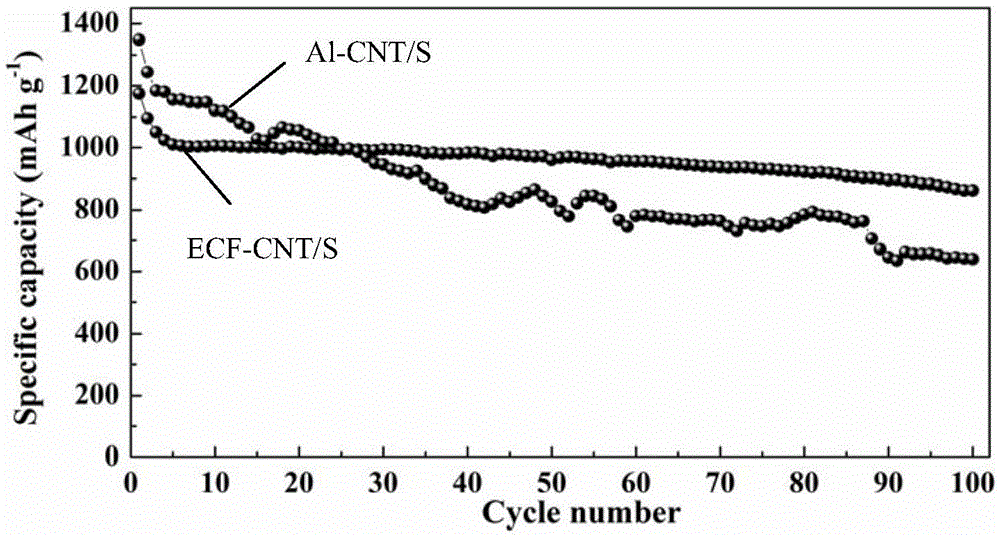

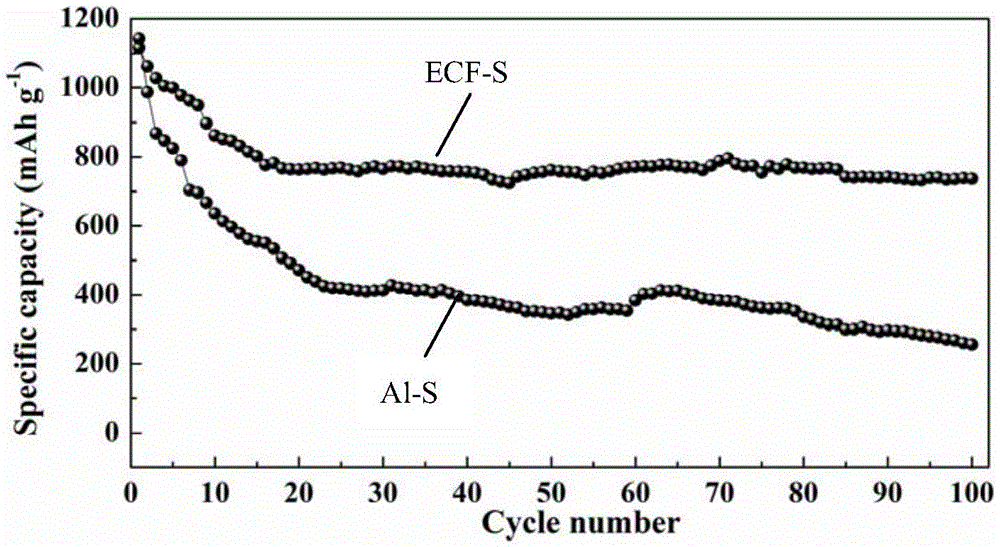

[0055] The three-dimensional carbon current collector for lithium-sulfur batteries in this embodiment is the three-dimensional carbon current...

Embodiment 2

[0066] The preparation method of the lithium-sulfur battery three-dimensional carbon current collector of this embodiment comprises the steps of: soaking the organic foaming material polyurethane foam with the organic solvent acetone for 3 hours, then ultrasonically treating it for 0.5 hour, washing it with distilled water for 3 times, and placing it in a vacuum drying oven , and dried at 120°C for 8h to obtain a carbon precursor. Under the protection of nitrogen atmosphere, the carbon precursor was heated up to 900°C at a heating rate of 5°C / min, kept for 4 hours, and cooled to room temperature naturally. After taking it out, it was cut to a suitable size with a cutting machine to obtain an elastic lithium-sulfur battery. Three-dimensional carbon current collector. The compressibility of the polyurethane foam mentioned above was 90%.

[0067] The three-dimensional carbon current collector for lithium-sulfur batteries in this embodiment is the three-dimensional carbon current...

Embodiment 3

[0077] The preparation method of the lithium-sulfur battery three-dimensional carbon current collector of this embodiment comprises the steps of: soaking the organic foaming material melamine foam in the organic solvent ethylene glycol for 6 hours, then ultrasonically treating it for 0.5 hours, washing it with distilled water for 3 times, and placing it in a vacuum-dried In an oven, dry at 60°C for 12 hours to obtain a carbon precursor. Under the protection of nitrogen atmosphere, the carbon precursor was heated up to 800°C at a heating rate of 5°C / min, kept for 2 hours, and cooled to room temperature naturally. After taking it out, it was cut to a suitable size with a cutting machine to obtain an elastic lithium-sulfur battery. Three-dimensional carbon current collector. The compressibility of the above-mentioned melamine foam material is 90%.

[0078] The three-dimensional carbon current collector for lithium-sulfur batteries in this embodiment is the three-dimensional carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com