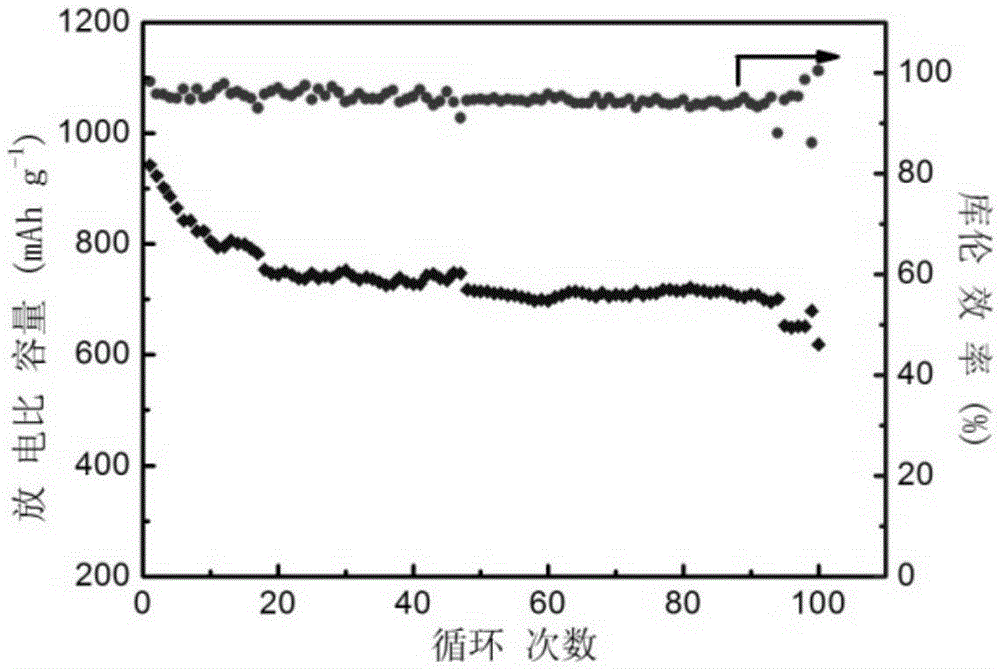

Method for preparing biomass activated carbon and application of biomass activated carbon to lithium sulfur batteries

A technology of activated carbon and biomass, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve the problems of low sulfur utilization rate, unfavorable electrode materials, and no consideration of the influence of pore structure on the electrochemical performance of batteries, etc., to achieve Rich specific surface area, sufficient chemical reaction, and good capacity retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: Pretreatment of raw materials

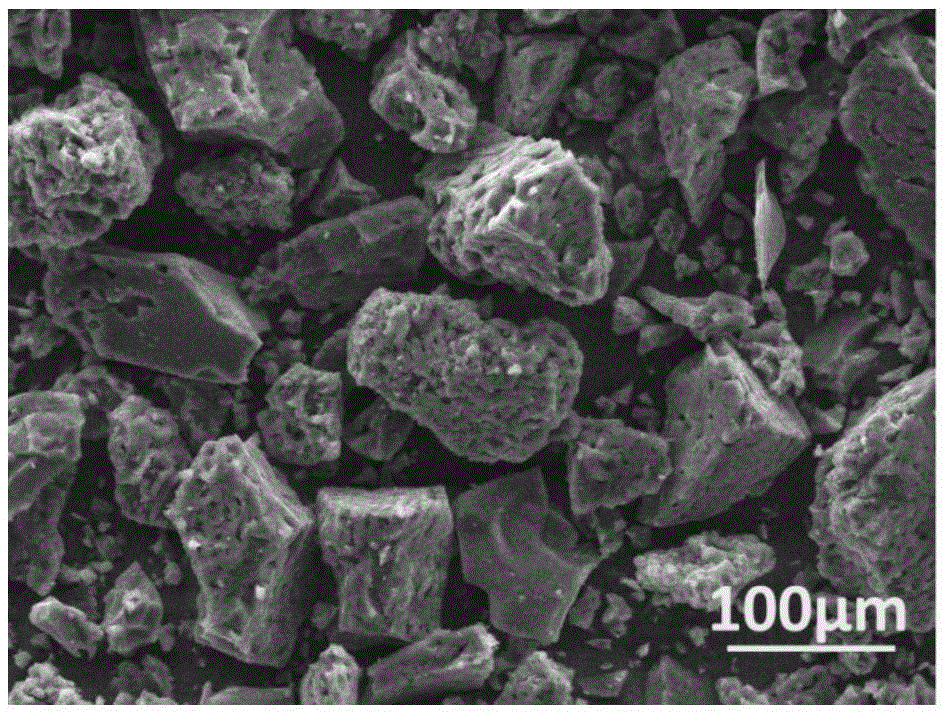

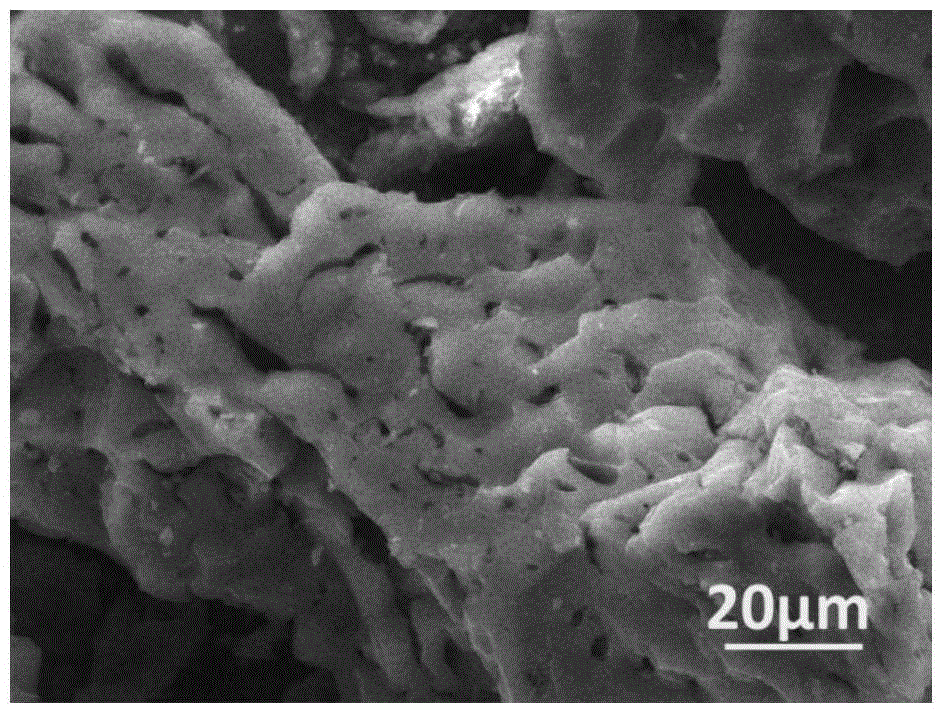

[0042] Crush a certain quality of peanut shells into granules with a particle size of ≤5mm, wash them in distilled water to remove dust and other impurities, and dry them in medium until the mass is no longer reduced. Take a certain amount of the peanut shells, with a mass fraction of 20 % ZnCl 2 The solution is mixed at a mass ratio of material to liquid of 1:4, packaged and soaked for 24 hours, transferred to a ceramic crucible, placed in a freezer, and frozen at minus 20°C for 60 hours.

[0043] Step 2: Preparation of Activated Carbon

[0044] Take out the frozen mixture, cover it and quickly put it into a muffle furnace with an initial temperature of about 100°C, heat it to 550°C at a rate of 10°C / min, keep it at this temperature for 2 hours, and let it cool naturally to Take it out after about 100°C, and let it cool down to room temperature naturally. The resulting product was taken out, and soaked in dilute hydrochloric a...

Embodiment 2

[0052] Step 1: Pretreatment of raw materials

[0053] Crush a certain quality of peanut shells into granules with a particle size of ≤5mm, wash them in distilled water to remove dust and other impurities, and dry them until the mass is no longer reduced. Take a certain amount of the peanut shells, with a mass fraction of 15% ZnCl 2 The solution was mixed at a material-to-liquid mass ratio of 1:5, packaged and soaked for 24 hours, the mixture was transferred to a ceramic crucible, placed in a freezer, and frozen at minus 30°C for 48 hours.

[0054] Step 2: Preparation of Activated Carbon

[0055] Take out the frozen mixture, cover it and quickly put it into a muffle furnace with an initial temperature of about 100°C, heat it to 500°C at a rate of 10°C / min, keep it at this temperature for 3 hours, and let it cool naturally to Take it out after about 100°C, and let it cool down to room temperature naturally. The resulting product was taken out and soaked in dilute hydrochloric...

Embodiment 3

[0060] Step 1: Pretreatment of raw materials

[0061] Crush a certain amount of walnut shells into granules with a particle size of ≤5mm, wash them in distilled water to remove dust and other impurities, and dry until the mass is no longer reduced. Take a certain amount of the walnut shells, with a mass fraction of 25% ZnCl 2 The solution was mixed at a material-to-liquid mass ratio of 1:3, packaged and soaked for 24 hours, the mixture was transferred to a ceramic crucible, placed in a freezer, and frozen at minus 25°C for 48 hours.

[0062] Step 2: Preparation of Activated Carbon

[0063] Take out the frozen mixture, cover it and quickly put it into a resistance furnace with an initial temperature of about 100°C, heat it to 650°C at a rate of 15°C / min, keep it at this temperature for 1.5 hours, and let it cool naturally to 100°C After about ℃, take it out and cool to room temperature. The resulting product was taken out and soaked in dilute hydrochloric acid with a mass fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average coulombic efficiency | aaaaa | aaaaa |

| Average coulombic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com