Superbattery polar plate containing vacuum puffed grapheme, preparation method thereof and lead acid superbattery assembled thereby

A vacuum puffing and super battery technology, which is applied to battery electrodes, lead-acid battery electrodes, lead-acid batteries, etc., can solve the problems of small specific capacitance and poor rate performance, and achieve the effects of improved rate performance, developed pores, and sufficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

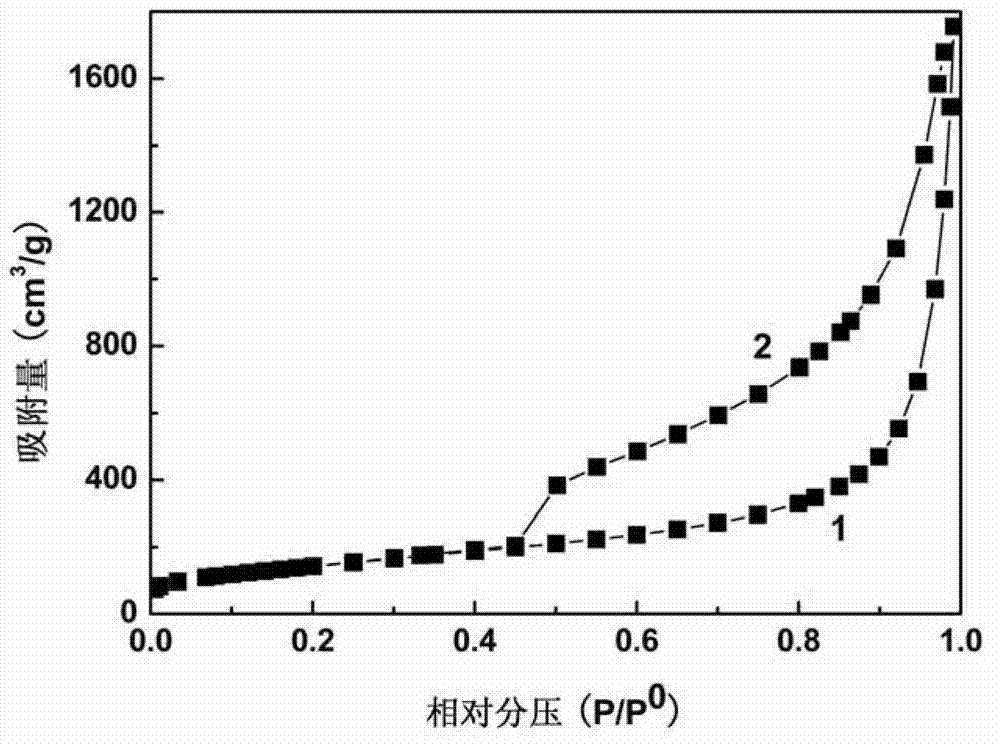

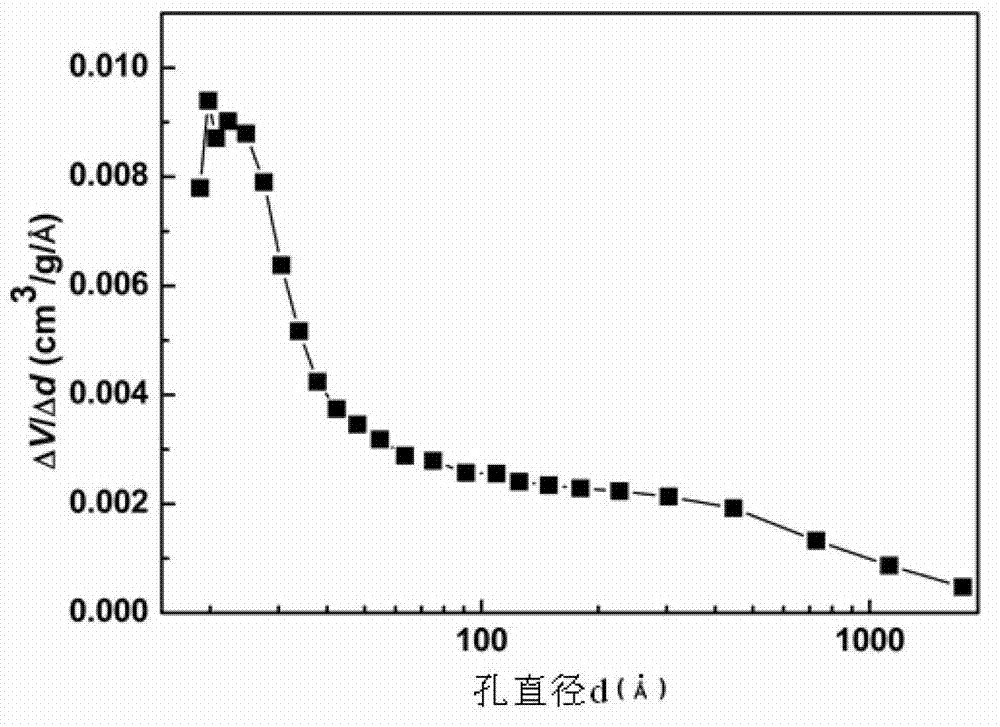

[0048] Embodiment 1: The super battery pole plate comprising vacuum expanded graphene of this embodiment is composed of a current collector and an electrode material coated on the current collector, and the electrode material includes a capacitive electrode active material and a battery electrode active material The capacitive electrode active material includes vacuum expanded graphene, and the mass of the vacuum expanded graphene accounts for 0.01% to 20% of the mass of the battery electrode active material.

[0049] In the super battery pole plate comprising vacuum expanded graphene of the present embodiment, the vacuum expanded graphene in the electrode paste is used as a capacitive electrode active material, and a capacitive current is provided through the charge and discharge process of the electric double layer on the rich surface of the vacuum expanded graphene; In the electrode paste, there is also an electrode active material of the battery that stores electrical energ...

specific Embodiment approach 2

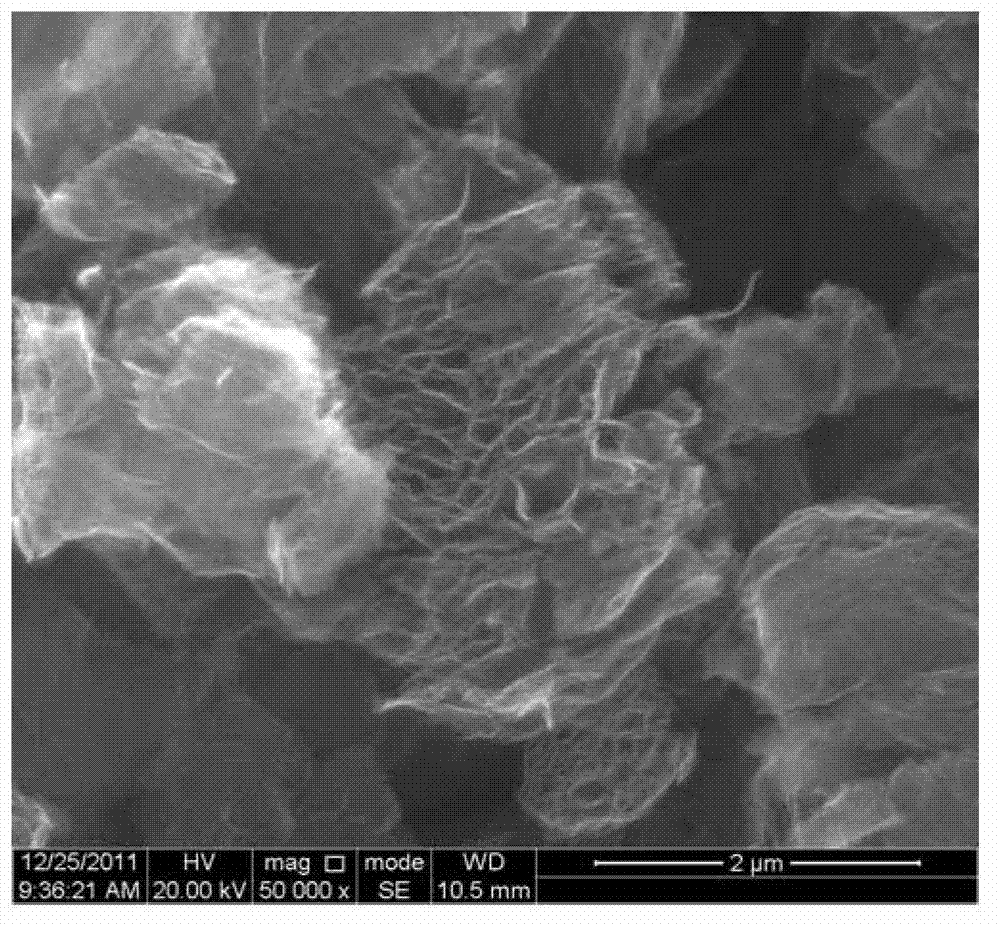

[0050] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the preparation method of vacuum expanded graphene is carried out according to the following steps:

[0051] 1. Oxidize graphite into graphite oxide;

[0052] 2. Put the graphite oxide obtained in step 1 into a vacuum heating furnace, first evacuate to -0.07MPa~-0.1MPa, then raise the temperature to 100℃~800℃ at a rate of 5℃ / min~100℃ / min and keep 1min to 3h to obtain vacuum-expanded graphene. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0053] Specific embodiment three: the difference between this embodiment and specific embodiment one is that the preparation method of vacuum expanded graphene is carried out according to the following steps:

[0054] 1. Oxidize graphite into graphite oxide;

[0055] 2. Put the graphite oxide obtained in step 1 into a vacuum heating furnace, first evacuate to -0.07MPa~-0.1MPa, then raise the temperature to 100℃~800℃ at a rate of 5℃ / min~100℃ / min and keep 1min~3h;

[0056] 3. Put the graphite oxide treated in step 2 in an atmosphere-protected heating furnace, and in an inert gas atmosphere, raise the temperature to 200-900°C at a rate of 1°C / min-100°C / min and keep it for 10min-3h. Vacuum expanded graphene is obtained. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com