Elemental sulfur anode of secondary lithium-sulfur battery and preparation method of elemental sulfur anode

A lithium-sulfur battery and elemental sulfur technology, applied in the field of electrochemical batteries, can solve the problems of cumbersome preparation process, uneven distribution of active material sulfur and conductive agent, etc., achieve uniform dispersion of sulfur and carbon, improve cycle stability, and increase conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

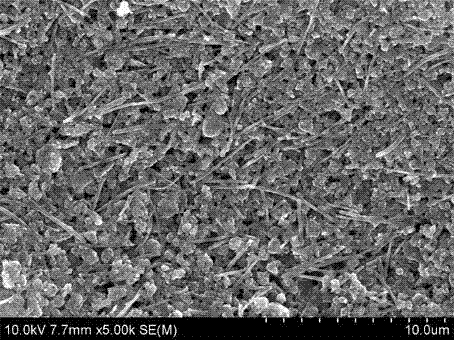

[0033] (1) Weigh sublimated sulfur:SP carbon black (hereinafter referred to as SP) according to the mass ratio: VGCF:PVDF=60:22:8:10, mix SP, VGCF and PVDF evenly, place in a closed glass bottle, and add A certain amount of NMP was stirred magnetically for 60 minutes to prepare a slurry in which the conductive agent was uniformly mixed, and the sublimated sulfur was reserved for the next step;

[0034] (2) Take a certain amount of CS 2 Liquid, the sublimated sulfur powder is configured as S-CS with a mass fraction of 10% 2 solution;

[0035] (3) the S-CS 2 Add the solution dropwise to the uniformly mixed early slurry prepared in step (1) through a peristaltic pump, and stir for 3 hours; then open the container and continue stirring for 30 minutes to obtain a uniformly mixed final slurry;

[0036] (4) Apply the final slurry on the corroded aluminum foil with a spatula, and dry it in vacuum at 50°C for 24 hours to obtain the final electrode sheet.

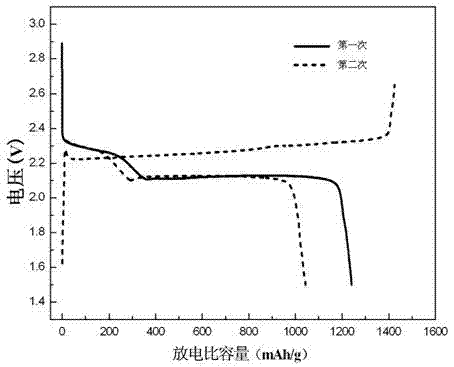

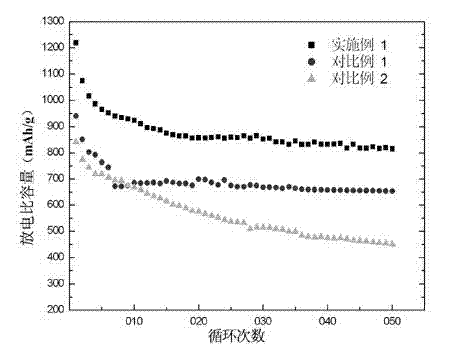

[0037] The final pole pie...

Embodiment 2

[0049] (1) Weigh the sublimed sulfur according to the mass ratio: SP:CNT:PVDF=66:16:8:10, mix SP, VGCF and PVDF evenly, place in a sealed glass bottle, add a certain amount of NMP, and stir magnetically 60 minutes to prepare the early slurry with conductive agent mixed uniformly, and the sublimated sulfur is reserved for the next step;

[0050] (2) Measure a certain amount of xylene liquid, and prepare the sublimated sulfur powder into an S-xylene solution with a mass fraction of 10%;

[0051] (3) Add the S-xylene solution dropwise to the uniformly mixed preliminary slurry prepared in step (1) through a peristaltic pump, and stir for 3 hours; then open the container and continue stirring for 30 minutes to obtain a uniformly mixed final slurry ;

[0052] (4) Apply the final slurry on the carbon-coated aluminum foil with a spatula, and dry it in vacuum at 50°C for 24 hours to obtain the final electrode sheet.

Embodiment 3

[0054] (1) Weigh the sublimed sulfur according to the mass ratio: SP:VGCF:PVDF=60:22:8:10, mix SP, VGCF and PVDF evenly and put it in a closed glass bottle, add a certain amount of NMP, and stir it magnetically 60 minutes to prepare the early slurry with conductive agent mixed uniformly, and the sublimated sulfur is reserved for the next step;

[0055] (2) Take a certain amount of DMSO solution, and prepare the sublimated sulfur powder into an S-DMSO solution with a mass fraction of 10%;

[0056] (3) Add the S-xylene solution dropwise to the homogeneously mixed early slurry prepared in step (1) through a peristaltic pump, heat to 115°C, and stir for 3 hours; then open the container and stop heating, continue Stir for 30min to make a uniform final slurry;

[0057] (4) Apply the final slurry on the carbon-coated aluminum foil with a spatula, and dry it in vacuum at 50°C for 24 hours to obtain the final electrode sheet.

[0058] The key to the preparation method provided by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com