Sealing material for sodium-sulfur cell and preparation thereof

A technology of sealing materials and sodium-sulfur batteries, which is applied in the field of energy materials, can solve problems such as poor thermal shock resistance and mismatching expansion coefficients, and achieve good thermal shock resistance and excellent matching effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

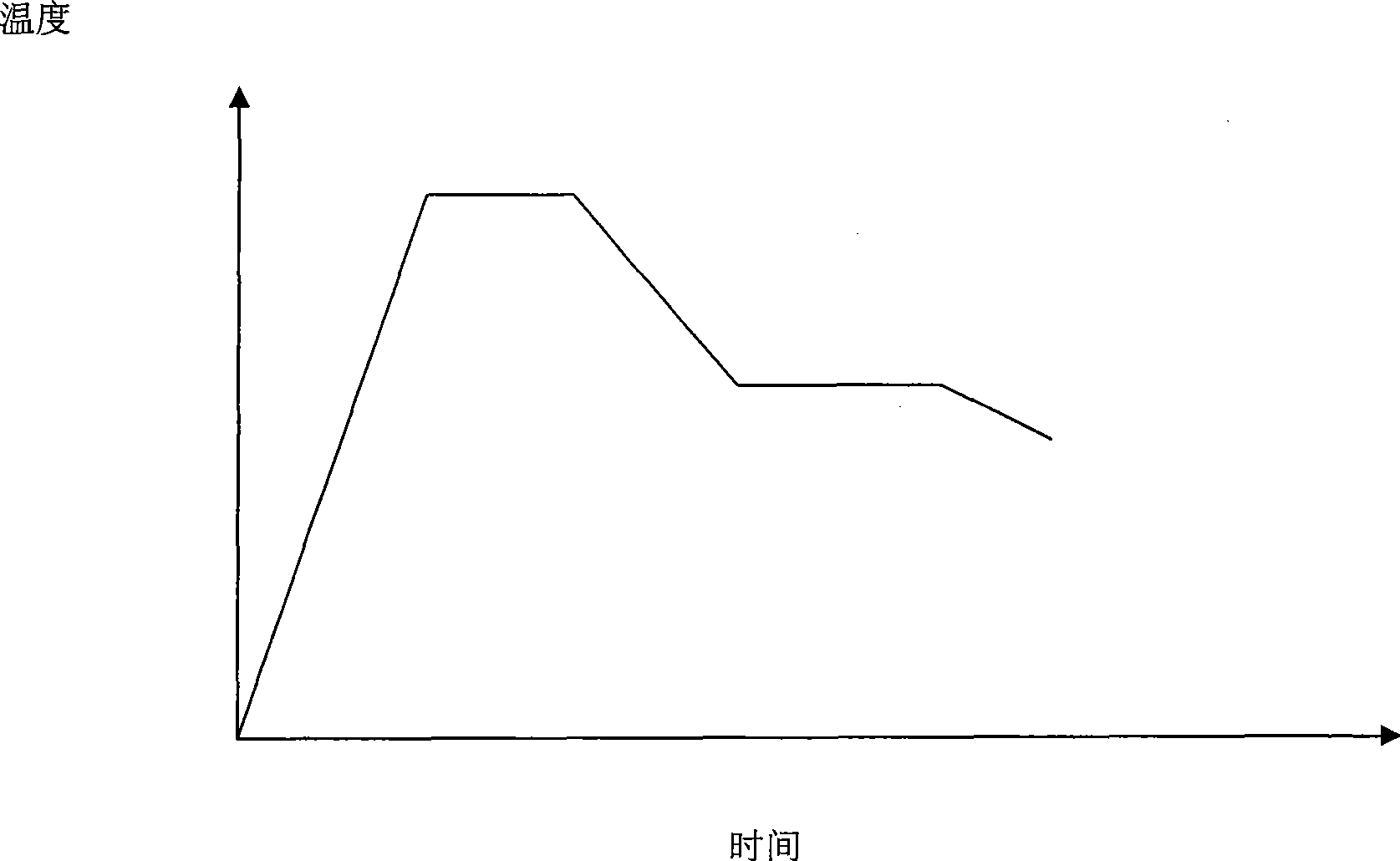

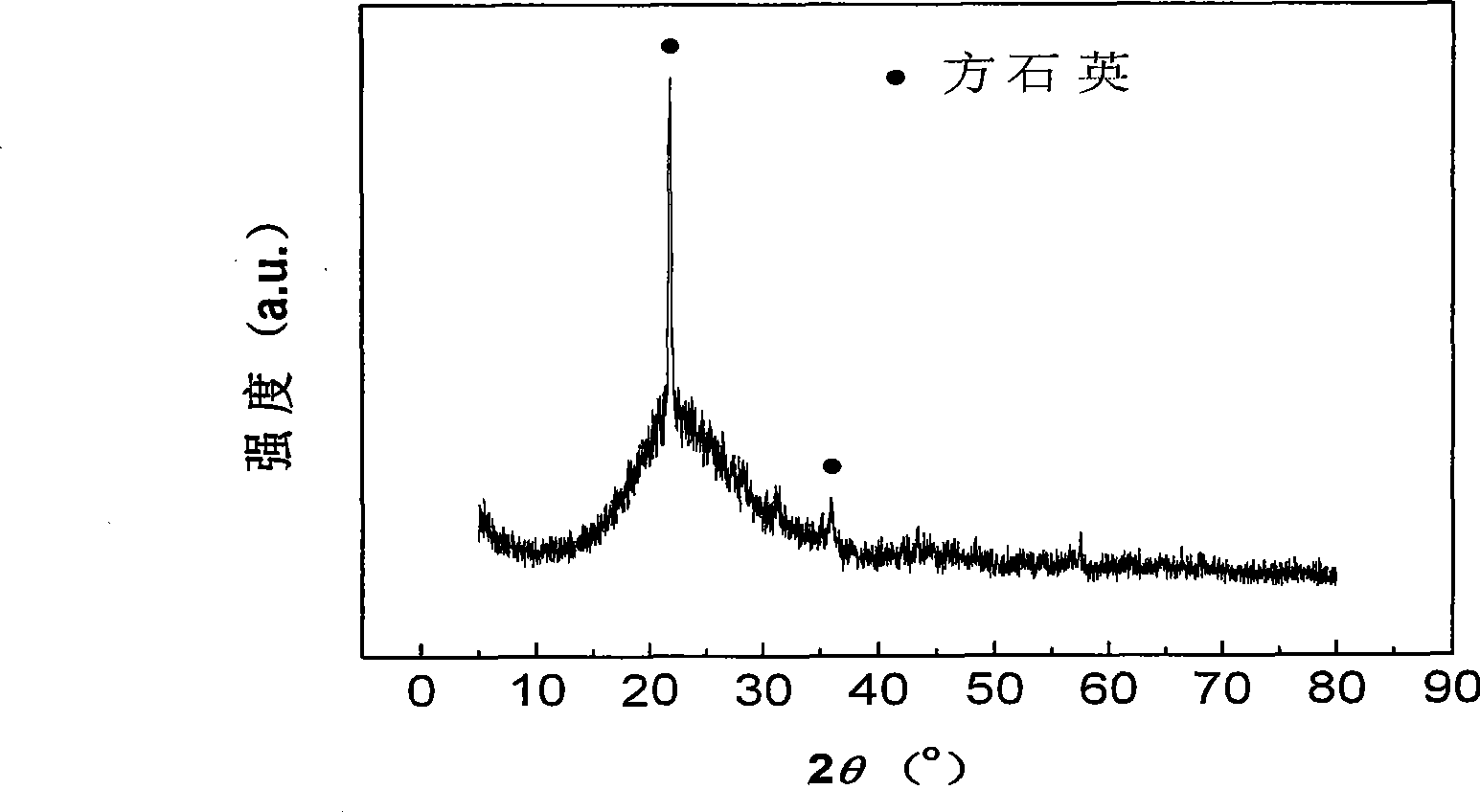

Embodiment 1

[0023] SiO 2 , Al 2 o 3 , H 3 BO 3 , Na 2 CO 3 , K 2 CO 3 ,TiO 2 , Y 2 o 3 The ingredients are designed according to the ratio of G1 in Table 1. All ingredients are analytically pure. They are ball milled in alcohol medium for 4 hours, dried, kept at 800°C for 0.5h, melted at 1400°C for 2h, poured into ice water and quenched to obtain Glass slag, glass powder obtained after ball milling. Pass through a 200-mesh sieve, add 2% PVB as a binding agent, and press into a rectangular strip of 6×6×27 mm by a tablet press. Insulate at 600°C for 2 hours to remove the binder, according to image 3 The sealing system is sealed, the sealing temperature is raised to 1000°C at 4°C / min, held for 15 minutes, lowered to the nucleation temperature of 600°C, held for 240 minutes, raised to the crystallization temperature of 850°C, held for 240 minutes. The final sealed glass-ceramic is obtained. The thermal expansion coefficient was measured with a thermal dilatometer, and the heati...

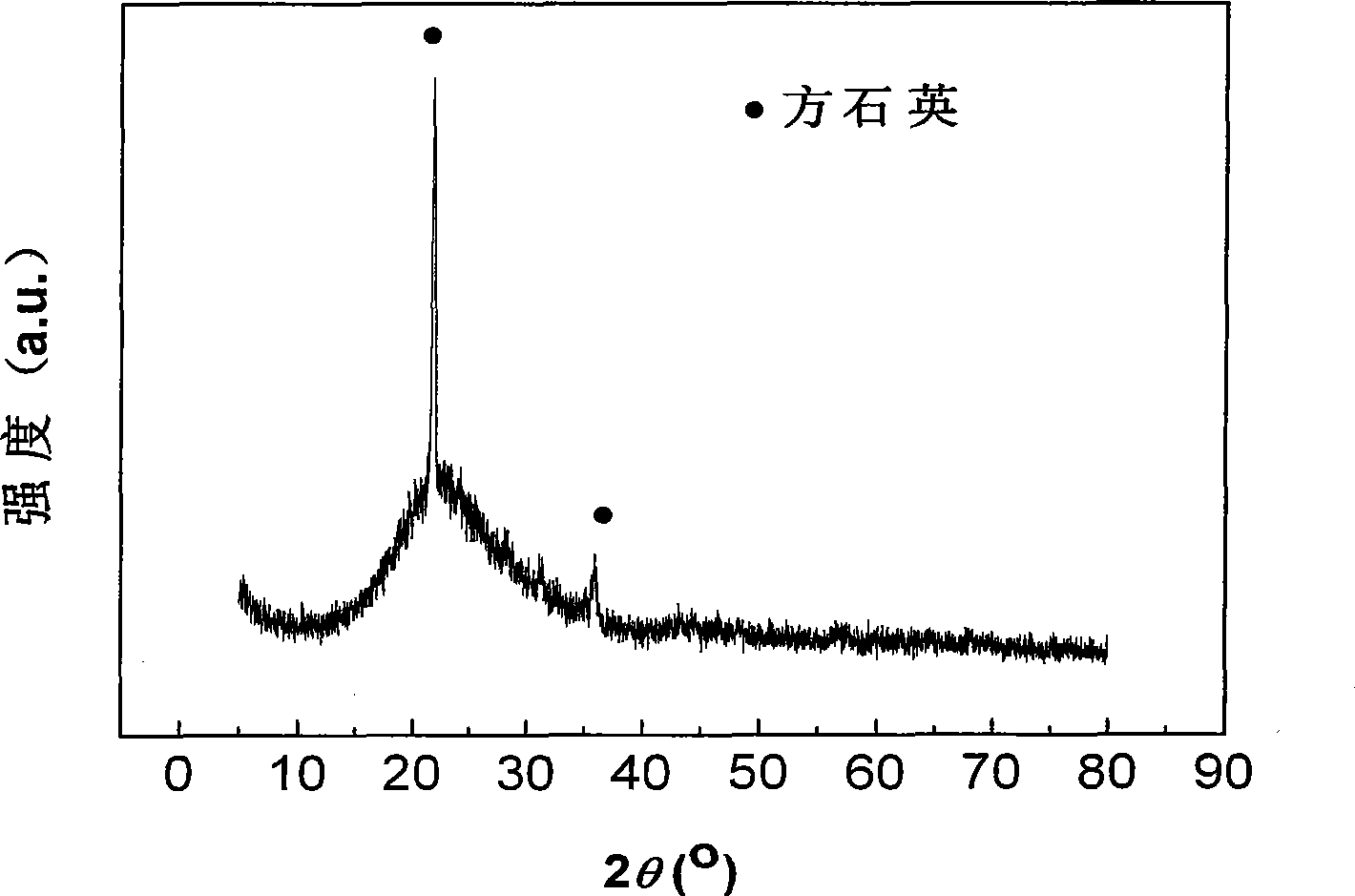

Embodiment 2

[0025] SiO 2 , Al 2 o 3 , H 3 BO 3 , Na 2 CO 3 , K 2 CO 3 ,TiO 2 , Y 2 o 3 The ingredients are designed according to the ratio of G2 in Table 1. All ingredients are analytically pure. They are ball milled in alcohol medium for 4 hours, dried, kept at 800°C for 0.5h, melted at 1400°C for 2h, poured into ice water and quenched to obtain Glass slag, glass powder obtained after ball milling. Pass through a 40-mesh sieve, add 2% PVB as a binding agent, and press into a rectangular strip of 6×6×27 mm by a tablet press. Insulate at 600°C for 2 hours to remove the binder, according to image 3 The sealing system is sealed, the sealing temperature is 1000°C, the sealing time is 15min, the nucleation is 240min at 700°C, the crystallization temperature is raised to 800°C, and the heat preservation is 400min. The final sealed glass-ceramic is obtained. The thermal expansion coefficient was measured with a thermal dilatometer, and the heating rate was 5°C / min. The thermal ex...

Embodiment 3

[0027] SiO 2 , Al 2 o 3 , H 3 BO 3 , Na 2 CO 3 , K 2 CO 3 ,TiO 2 , Y 2 o 3 The ingredients are designed according to the ratio of G3 in Table 1. All ingredients are analytically pure. They are ball milled in alcohol medium for 4 hours, dried, kept at 800°C for 0.5h, melted at 1400°C for 2h, poured into ice water and quenched to obtain Glass slag, glass powder obtained after ball milling. Pass through a 60-mesh sieve, add 2% PVB as a binding agent, and press into a rectangular strip of 6×6×27 mm by a tablet press. Insulate at 600°C for 2 hours to remove the binder, according to image 3 The sealing system is sealed, the sealing temperature is 1000°C, the sealing time is 15min, the nucleation is 240min at 700°C, the crystallization temperature is raised to 800°C, and the heat preservation is 400min. The final sealed glass-ceramic is obtained. The thermal expansion coefficient was measured with a thermal dilatometer, and the heating rate was 5°C / min. The thermal ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

| Thermal expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com