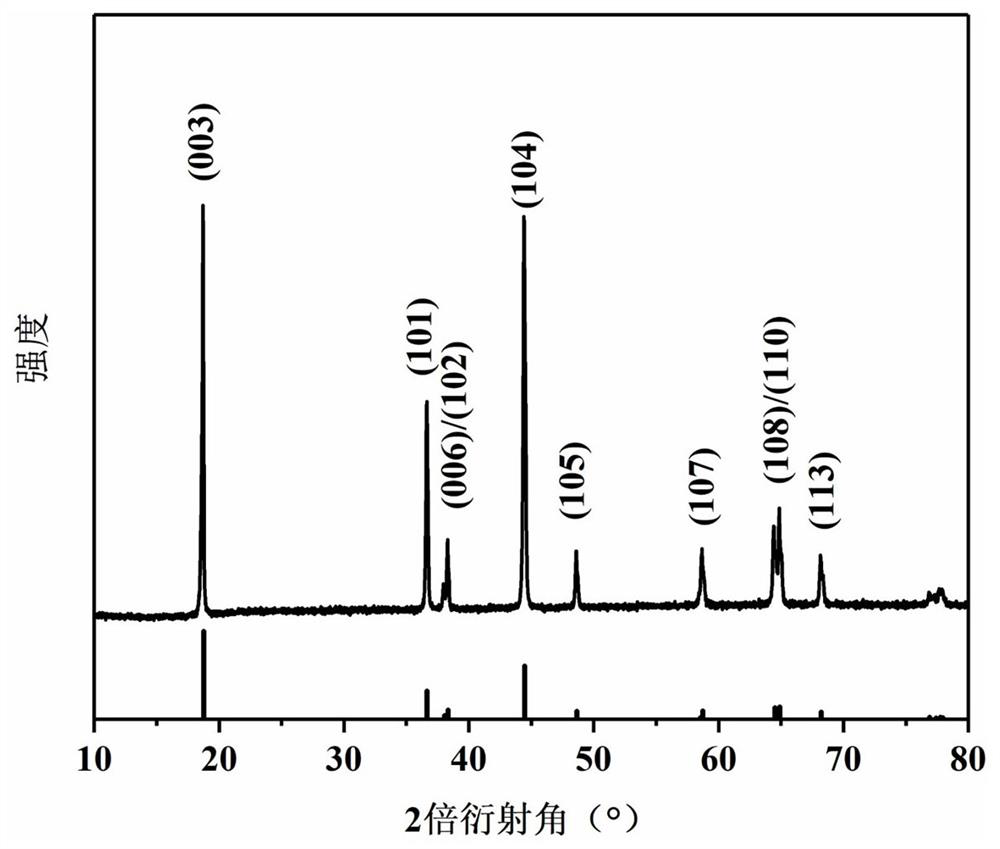

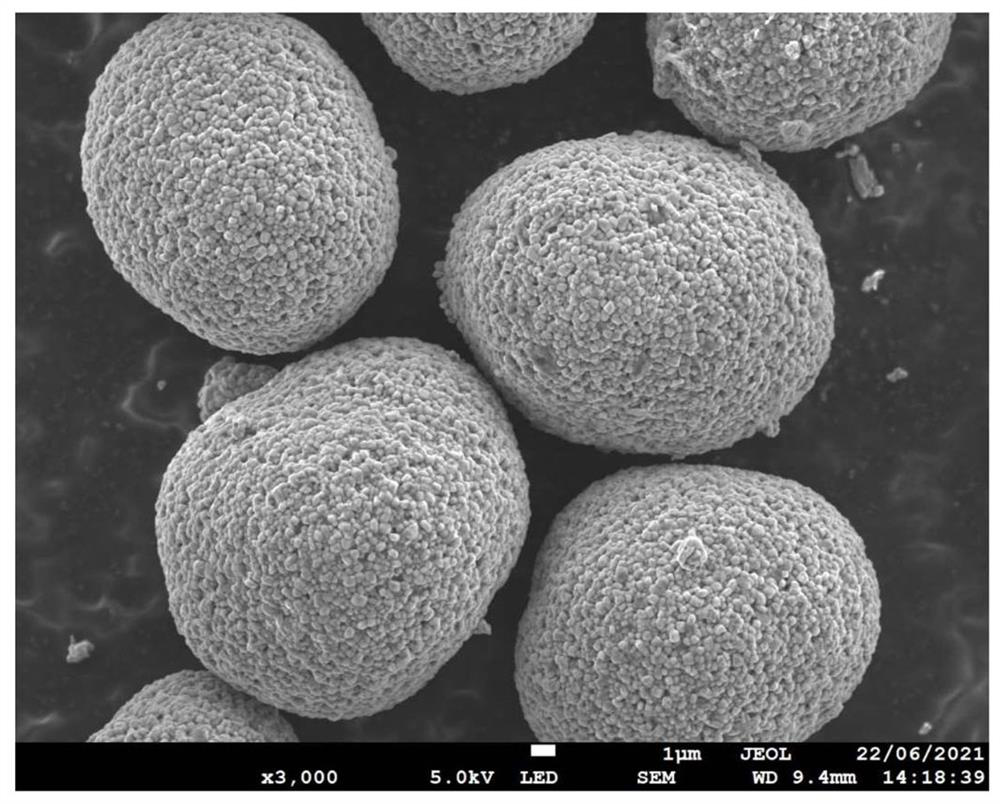

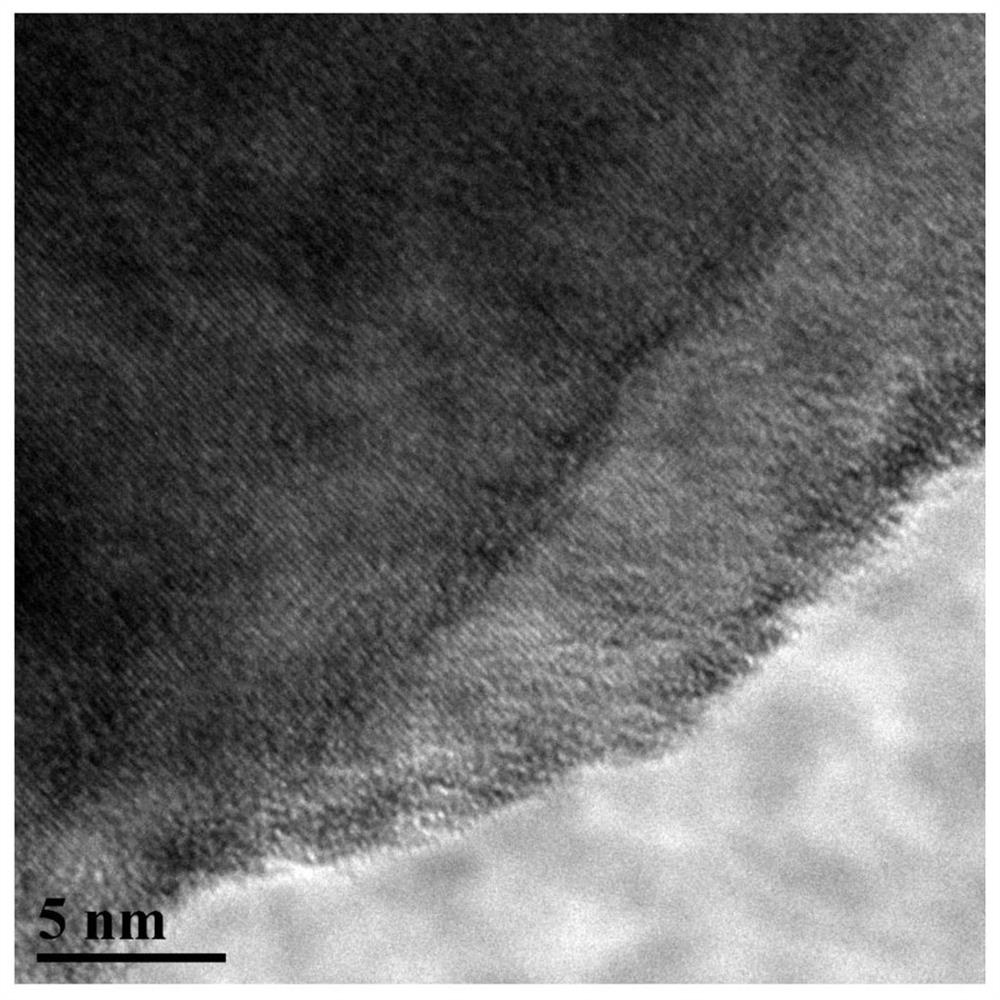

Preparation method of high-voltage positive electrode material with core-shell structure

A technology of positive electrode material and core-shell structure, applied in the field of positive electrode material preparation, can solve problems affecting material performance, poor dispersion effect, uneven coating, etc., achieve excellent rate performance, improve electrochemical performance, and structural stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a high-voltage cathode material with a core-shell structure, comprising the following steps:

[0044] (1) Weigh 0.0071g (0.028625mmol) of nickel acetate, 0.02104g (0.085875mmol) of manganese acetate, 0.0079g (0.120225mmol) of lithium acetate and dissolve them in 25mL of absolute ethanol by ultrasonic (ultrasonic power 40kHz) for 0.5h, and then Stir at 400r / min to obtain nickel-manganese-lithium-containing solution;

[0045] (2) Weigh 1g of ternary cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Dissolve in 25mL of absolute ethanol and disperse by ultrasonic (ultrasonic power 40kHz) for 0.5h, then gradually add the nickel-manganese-lithium solution prepared in step (1) to the solution at a rate of 25 drops / min, and continue to disperse at 400r / min after stirring for 5 hours, heat up to 70°C and stir until evaporated to dryness to obtain a powder precursor;

[0046] (3) Dry the powder precursor obtained in step (2) at 110°C for 2h, transfer it to ...

Embodiment 2

[0056] A method for preparing a high-voltage cathode material with a core-shell structure, comprising the following steps:

[0057] (1) Weigh 0.015048g (0.05725mmol) of nickel sulfate, 0.029026g (0.17175mmol) of manganese sulfate, 0.015866g (0.24045mmol) of lithium acetate and dissolve them in 30mL of absolute ethanol for 1h, then stir to obtain a solution containing nickel, manganese and lithium;

[0058] (2) Weigh 1g of ternary cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Dissolve in 20mL of absolute ethanol and sonicate for 0.5h, then gradually add the nickel-manganese-lithium solution prepared in step (1) to the solution at a rate of 30 drops / min, and continue stirring for 4h after the addition is complete, then raise the temperature to 60°C Stir until evaporated to dryness to obtain a powder precursor;

[0059] (3) Dry the powder precursor obtained in step (2) at 100°C for 3 hours, transfer it to a tube furnace in an oxygen atmosphere, raise the temperature to 750°C at...

Embodiment 3

[0064] A method for preparing a high-voltage cathode material with a core-shell structure, comprising the following steps:

[0065] (1) Weigh 0.021369g (0.085875mmol) nickel acetate, 0.063142g (0.257625mmol) manganese acetate, 0.013325g (0.180338mmol) lithium carbonate, dissolve in 20mL absolute ethanol and sonicate for 0.5h, then stir to obtain nickel-manganese-lithium solution ;

[0066] (2) Weigh 1g of ternary cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 Dissolve in 30mL of absolute ethanol and sonicate for 0.5h, then gradually add the nickel-manganese-lithium solution prepared in step (1) to the solution at a rate of 20 drops / min, and continue stirring for 3h after the addition is complete, then raise the temperature to 50°C Stir until evaporated to dryness to obtain a powder precursor;

[0067] (3) Dry the powder precursor obtained in step (2) at 90°C for 4 hours, transfer it to a tube furnace and raise the temperature to 800°C at a rate of 5°C / min under an oxygen atm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com