Lithium-sulfur battery anode material and preparation method thereof and lithium-sulfur battery

A technology for lithium-sulfur batteries and cathode materials, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of reduced ion conductivity, battery performance attenuation, low battery capacity, etc., and suppress the increase of battery internal resistance , reduce battery capacity attenuation, and improve the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

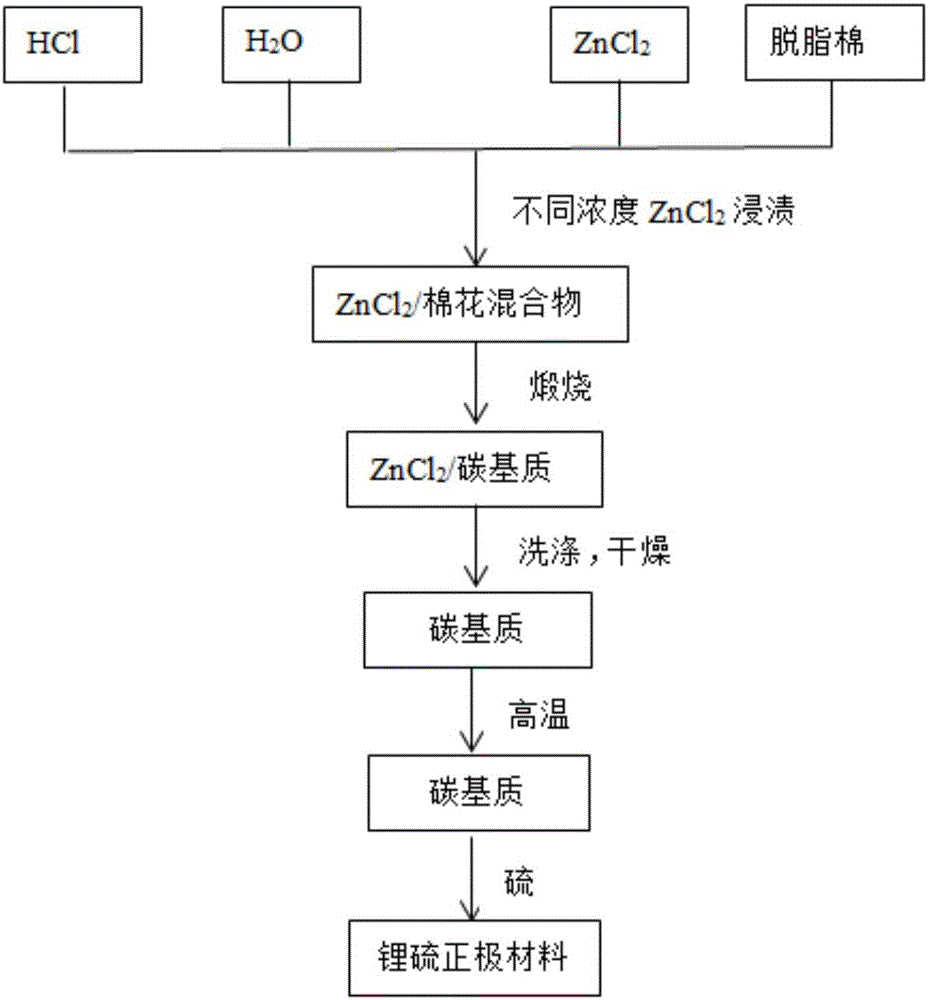

[0052] like figure 1 Shown, the invention provides a kind of preparation method of lithium-sulfur battery cathode material, it comprises the following steps:

[0053] S1. Impregnation of cotton: first prepare a hydrochloric acid solution of zinc chloride with a mass fraction of 10%-50%, wherein the concentration of hydrochloric acid is 0.1mol / L-0.4mol / L. Take 5g of cotton and immerse in 150g of hydrochloric acid solution, keep it sealed at 20-100°C for 10-24h, then remove the excess solution, the weight of the mixture is 10-18 times the mass of cotton, and then dry the resulting mixture at 80-120°C for 1-5h . Then keep the product at 40-100°C for 5-50d to finally get a gray or brown solid.

[0054] S2. Preparation of porous carbon matrix: calcining the above solid at 450-850° C. for 30 min-10 h in a protective atmosphere (preferably nitrogen or argon). The calcined product is then heated in 0.2mol / L-5mol / L hydrochloric acid at 50-110°C for 0.5-5h, filtered, washed with deio...

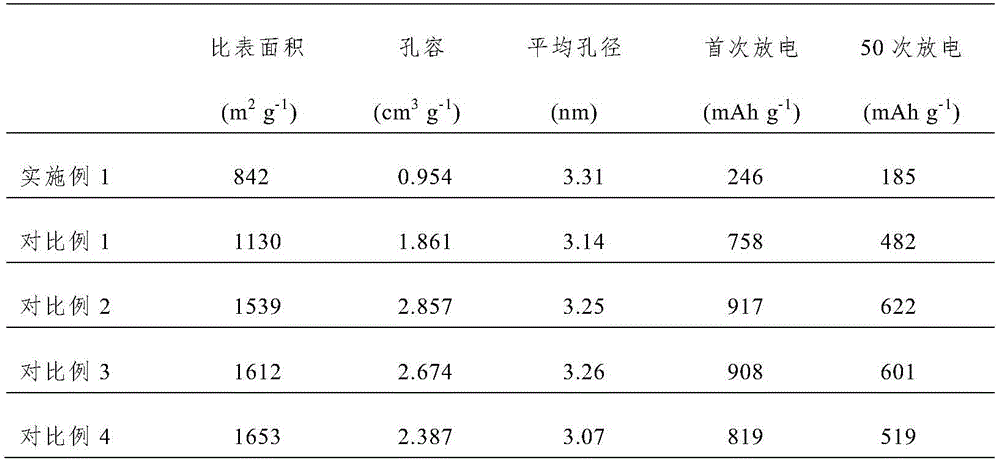

Embodiment 1

[0062] A preparation method for a lithium-sulfur battery positive electrode material, comprising the following steps:

[0063] S1. Cotton impregnation: first prepare a zinc chloride hydrochloric acid solution with a mass fraction of 10%, wherein the concentration of hydrochloric acid is 0.2 mol / L. Take 5g of cotton soaked in 150g of hydrochloric acid solution and keep it sealed at 70°C for 12h, then remove the excess solution. At this time, the weight of the mixture is 57.3g, and then dry the resulting mixture at 100°C for 2h. The product was then incubated at 65°C for 35 days to finally obtain a gray or brown solid.

[0064] S2. Preparation of porous carbon matrix: calcining the above solid at 550° C. for 1 h under the protection of argon. Then the calcined product was heated in 0.5 mol / L hydrochloric acid at 100°C for 2 hours, washed with deionized water and dried. Finally, the prepared product was dried at 80° C. for 4 hours, and calcined at 1000° C. for 1.5 hours under t...

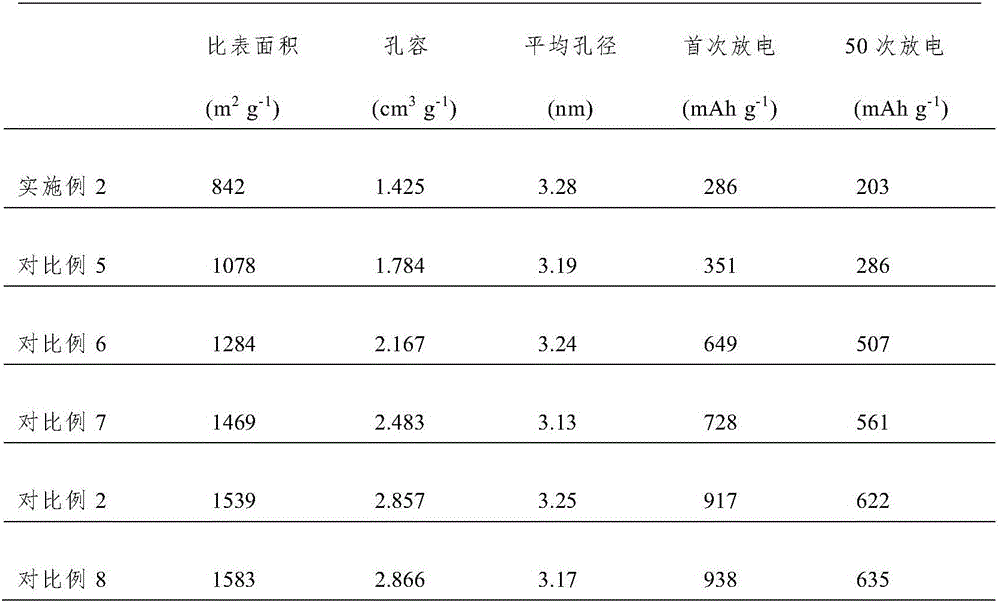

Embodiment 2

[0079] A preparation method for a lithium-sulfur battery positive electrode material, comprising the following steps:

[0080] S1. Impregnation of cotton: first prepare a hydrochloric acid solution of zinc chloride with a mass fraction of 30%, wherein the concentration of hydrochloric acid is 0.2 mol / L. Take 5g of cotton soaked in 150g of hydrochloric acid solution and keep it sealed at 70°C for 12h, then remove the excess solution. At this time, the weight of the mixture is 78.5g, and then dry the resulting mixture at 100°C for 2h. The product was then incubated at 65°C for 1 d, and a gray or brown solid was finally obtained.

[0081] S2. Preparation of porous carbon matrix: calcining the above solid at 550° C. for 1 h under the protection of argon. Then the calcined product was heated in 0.5 mol / L hydrochloric acid at 100°C for 2 hours, washed with deionized water and dried. Finally, the prepared product was dried at 80° C. for 4 hours, and calcined at 1000° C. for 1.5 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com