Upright graphene/nano-silver composite material and preparation method and application thereof

A composite material and nano-silver technology, which is applied in the direction of electrode carriers/current collectors, electrical components, battery electrodes, etc., can solve the problems of lower battery energy density, low microstructure tortuosity, and limited size growth, and achieve large-capacity lithium Volume, strong modifiability, and the effect of eliminating lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

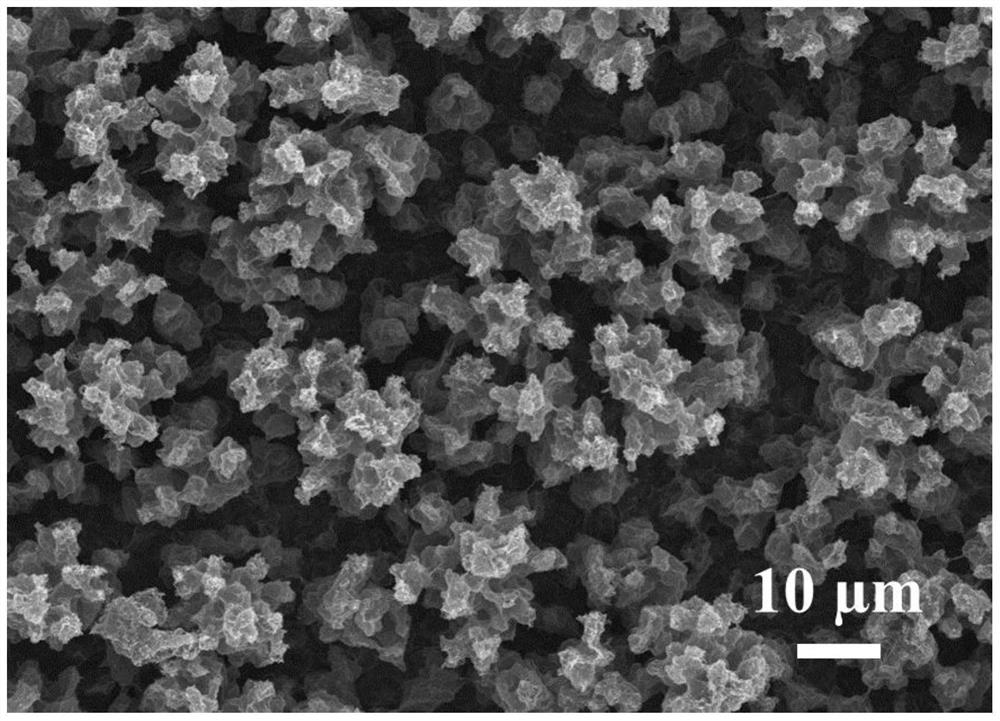

[0050] In the preparation method of the present embodiment, the first step to the sixth step are basically the same as Comparative Example 1, the difference is:

[0051] In the present embodiment, the simultaneous spraying time in the fourth step is adjusted to 18h;

[0052] And, this embodiment also includes:

[0053] The seventh step is to mix the commercially available nano-silver aqueous solution with absolute ethanol, the volume ratio of water and ethanol is 1:3, and the concentration is prepared to be 2 mg mL -1 Nano silver solution;

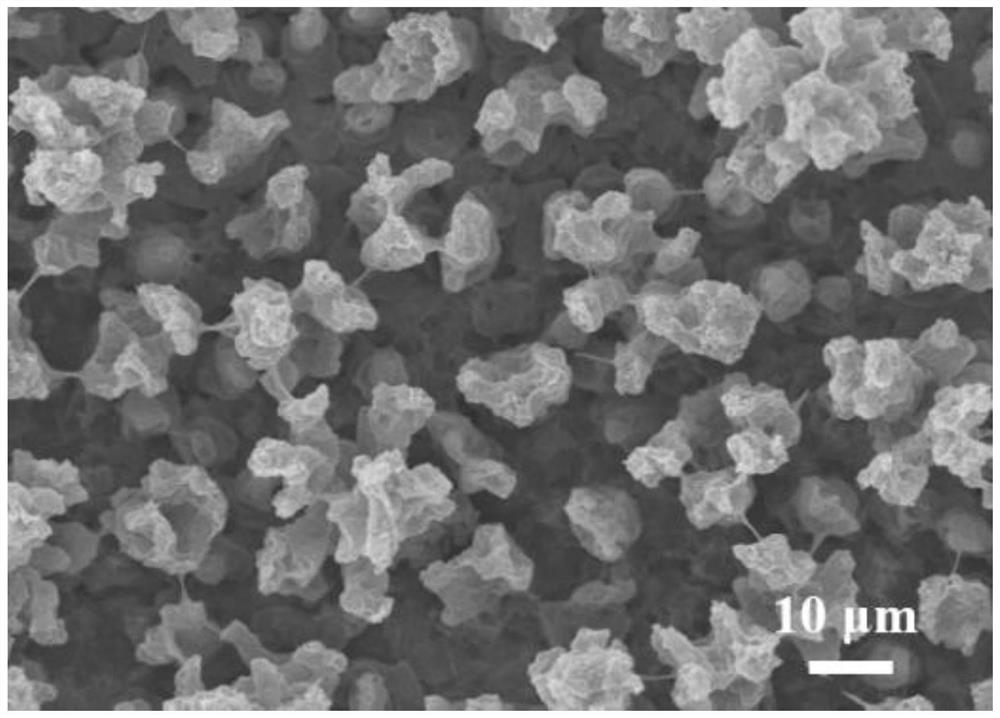

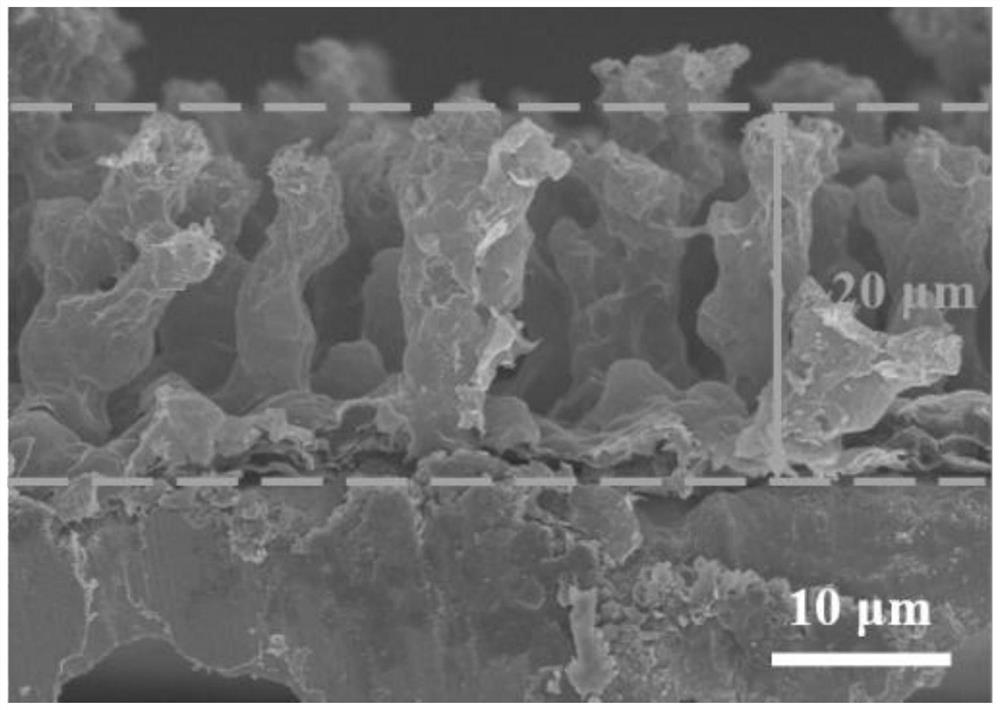

[0054] In the eighth step, immerse the columnar upright graphene array material obtained in the sixth step in the nano-silver solution obtained in the seventh step, take it out after a while, and dry it in vacuum at 60°C for 5 hours. The nano-silver is attached to the surface of the graphene, and the dipped Columnar upright graphene array material with nano silver;

[0055] In the ninth step, the columnar upright graphene array material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com