Titanium/graphene nanoribbon composite anode material and preparation method thereof

A technology of graphene nanobelts and nanocomposites, which is applied in the direction of negative electrodes, nanotechnology, nanotechnology, etc., can solve the problems of complex process and difficult large-scale preparation, and achieve simple process, excellent electrochemical performance, and good charging. Effect of Discharge Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A titanium dioxide / graphene nanoribbon composite negative electrode material

[0040] A quasi-one-dimensional nanocomposite material formed by titanium dioxide confined in graphene nanoribbons in the form of nanoparticles; the mass fraction of graphene nanoribbons in the titanium dioxide / graphene nanoribbon composite negative electrode material is 53% (wherein, graphene nanoribbons ribbon 12.4mg, titanium dioxide 11.0mg), the width of the graphene nanoribbon is 40nm, the average thickness is 3nm, and the particle diameter of the titanium dioxide is 8nm.

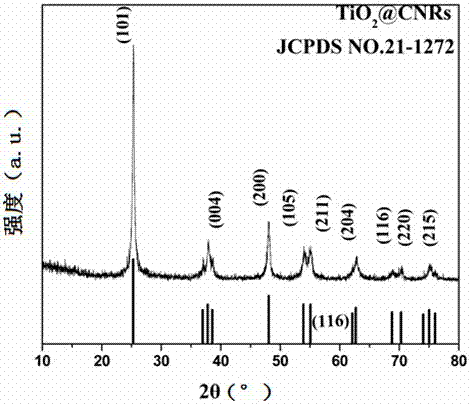

[0041] Depend on figure 1 It can be seen that the titanium dioxide / graphene nanobelt composite negative electrode material in the embodiment of the present invention is anatase titanium dioxide.

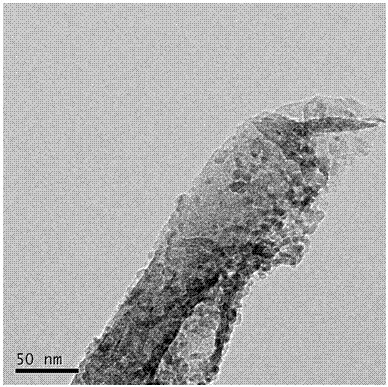

[0042] Depend on figure 2 It can be seen that on the graphene nanobelt of the quasi-one-dimensional nanostructure of the titanium dioxide / graphene nanoribbon composite negative electrode material in the embodiment of the p...

Embodiment 2

[0052] A titanium dioxide / graphene nanoribbon composite negative electrode material

[0053] A quasi-one-dimensional nanocomposite material formed by titanium dioxide confined in graphene nanoribbons in the form of nanoparticles; the mass fraction of graphene nanoribbons in the titanium dioxide / graphene nanoribbon composite negative electrode material is 42.2% (wherein, graphene nanoribbons ribbon 24.8mg, titanium dioxide 34.0mg), the width of the graphene nanoribbon is 50 nm, the average thickness is 4nm, and the particle size of the titanium dioxide is 15nm.

[0054] A preparation method of titanium dioxide / graphene nanobelt composite negative electrode material

[0055] (1) Add 40 mg of graphene oxide nanoribbons into 90 mL of propanol, and ultrasonically disperse at 30 kHz, 20°C for 3 hours to obtain a suspension of graphene oxide nanoribbons;

[0056] (2) Add 150 μL tetrabutyl titanate and 150 μL deionized water to the graphene oxide nanoribbon suspension obtained in ste...

Embodiment 3

[0063] A titanium dioxide / graphene nanoribbon composite negative electrode material

[0064] It is a quasi-one-dimensional nanocomposite material formed by titanium dioxide confined in graphene nanobelts in the form of nanoparticles; in the titanium dioxide / graphene nanobelt composite negative electrode material, the mass content of graphene nanobelts is 39.3% (wherein graphite 18.6 mg of graphene nanobelts, 28.7 mg of titanium dioxide), the width of the graphene nanobelts is 90 nm, the average thickness is 5 nm, and the particle size of the titanium dioxide is 25 nm.

[0065] A preparation method of titanium dioxide / graphene nanobelt composite negative electrode material

[0066] (1) Add 30 mg of graphene oxide nanobelts into 80 mL of ethanol, and ultrasonically disperse at 40kHz, 45°C for 2 hours to obtain a suspension of graphene oxide nanobelts;

[0067] (2) Add 200 μL tetrabutyl titanate and 200 μL deionized water to the graphene oxide nanoribbon suspension obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com