Preparation method of porous copper current collector, porous copper current collector, negative electrode and battery

A technology of porous copper and current collector, applied in the field of energy storage, can solve the problem of difficulty in ensuring the normal use of metal negative electrodes, and achieve the effects of low cost, uniform distribution and long cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

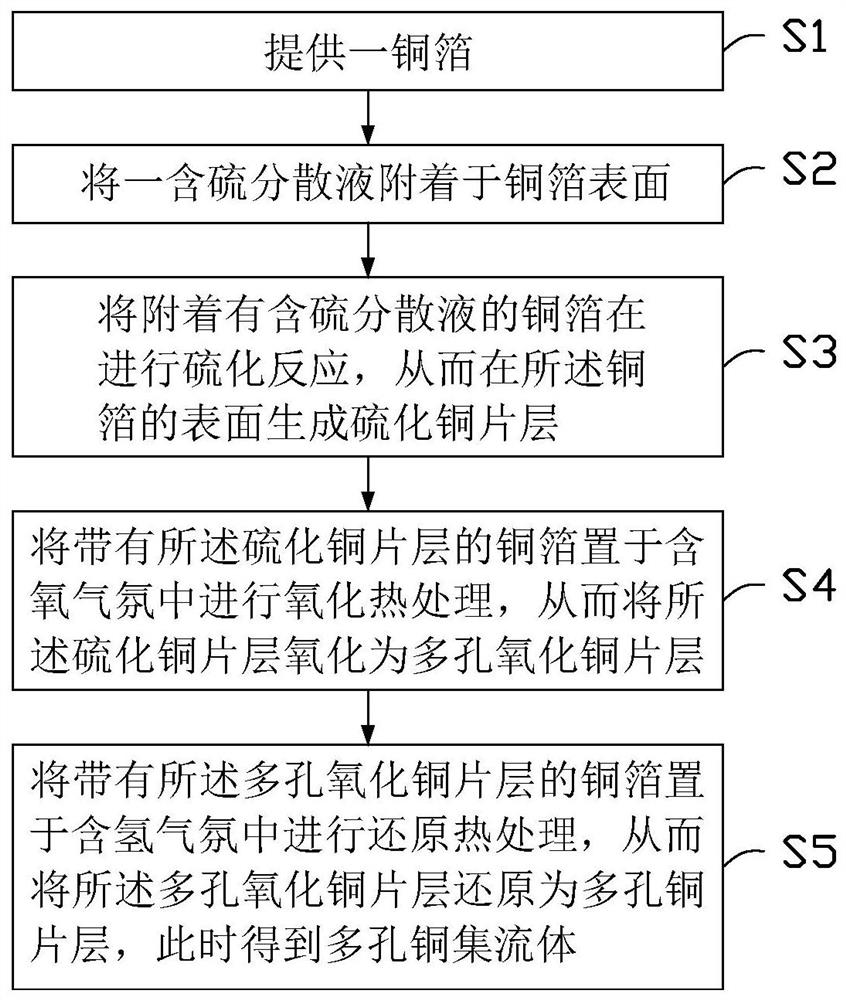

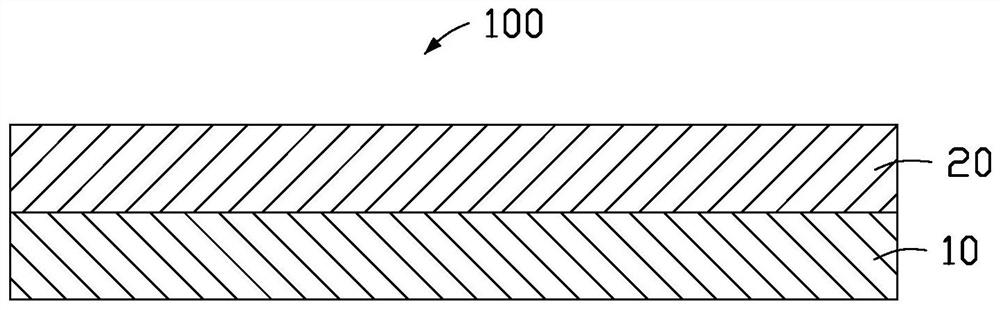

[0031] refer to figure 1 , a preferred embodiment of the present invention provides a method for preparing a porous copper current collector 100, the preparation method comprising the following steps:

[0032] Step S1, providing a copper foil;

[0033] Step S2, attaching a sulfur-containing dispersion to the surface of the copper foil;

[0034] Step S3, performing a vulcanization reaction on the copper foil attached with the sulfur-containing dispersion, thereby forming a copper sulfide sheet layer on the surface of the copper foil;

[0035] Step S4, placing the copper foil with the copper sulfide layer in an oxygen-containing atmosphere for oxidation heat treatment, so as to oxidize the copper sulfide layer into a porous copper oxide layer;

[0036] Step S5, placing the copper foil with the porous copper oxide layer in a hydrogen-containing atmosphere for reduction heat treatment, so as to reduce the porous copper oxide layer to a porous copper layer, and obtain a porous co...

Embodiment 1

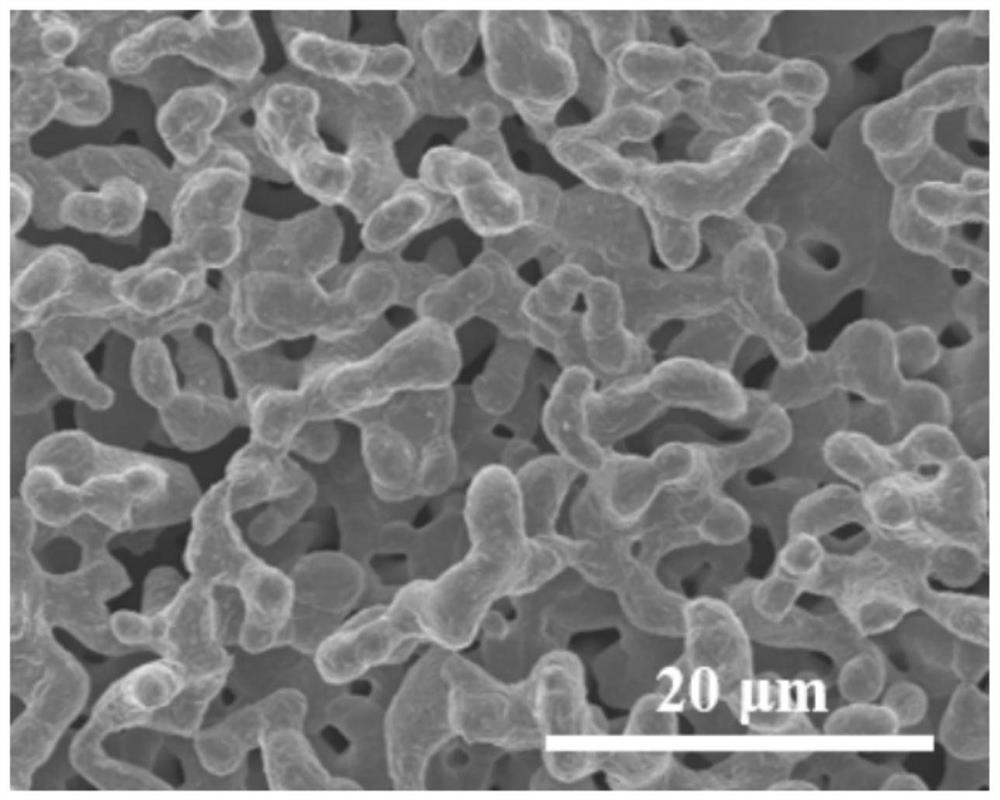

[0050] Take a commercial copper foil with a thickness of 100 μm, and ultrasonicate it in ethanol for 30 minutes; dissolve sulfur powder, carbon black and PVDF in the solvent NMP with a mass ratio of 7:2:1, and prepare a sulfur-containing dispersion with a sulfur concentration of 10 mg / mL. liquid; drop the sulfur-containing dispersion liquid on the surface of copper foil, and control the sulfur load to be about 1 mg / cm 2 , Vulcanization reaction at 60°C for 24h; then put the copper foil in an air atmosphere, and carry out oxidation treatment at 600°C for 4h; place the oxidized copper foil in hydrogen / argon (5%H 2 +95% Ar) atmosphere, thermal reduction treatment at 500° C. for 2 hours, to obtain a porous copper current collector 100 .

Embodiment 2

[0052] The difference from Example 1 is that the concentration of the sulfur-containing dispersion in this example is 20 mg / mL, and the sulfur load on the surface of the copper foil is about 2 mg / cm 2 .

[0053] Other steps are the same as in Example 1 and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com