Preparation method of hollow spherical negative electrode material vanadium phosphate/carbon for lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficulty in controlling the morphology and characteristics of vanadium phosphate materials, influence on the electrochemical performance of materials, and low industrialization prospects, and achieve Coulomb efficiency. Stable, good cycle stability, strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Add 10mmol (1169.8mg) ammonium metavanadate to 250mL ultrapure water, heat to 60°C, and keep stirring at 400 rpm until dissolved, then add 10mmol (1150.3mg) ammonium dihydrogen phosphate, Heat to 70°C and keep stirring at 500 rpm until dissolved, finally add 0.5mmol (4000mg) polyvinylpyrrolidone, heat to 70°C, and keep stirring at 400 rpm until dissolved to obtain the precursor solution;

[0037] (2) Spray-dry the precursor solution obtained in step (1), wherein the inlet temperature is 220°C and the flow rate of the liquid is 600mL / h to obtain the precursor of vanadium phosphate / carbon material;

[0038] (3) The vanadium phosphate / carbon material precursor obtained in step (2) was heated to 750°C at a rate of 5°C / min under high-purity argon gas, and kept for 8 hours to obtain a hollow spherical lithium-ion battery negative electrode material vanadium phosphate / carbon.

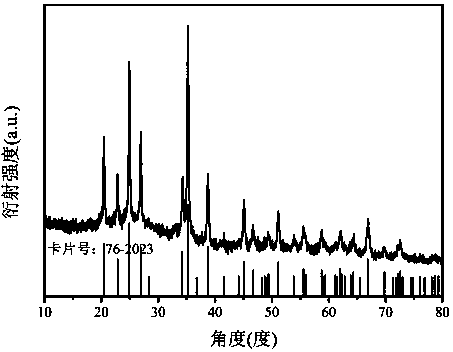

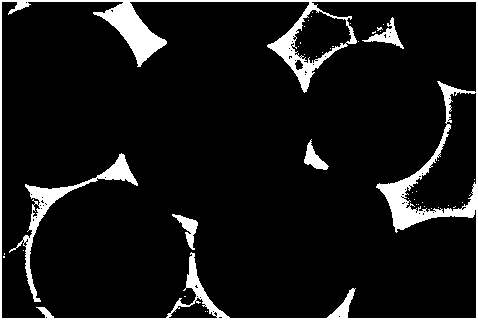

[0039] Such as figure 1 As shown, the peak value of vanadium phosphate / carbon of the hollow ...

Embodiment 2

[0047] (1) Add 5mmol (584.9mg) ammonium metavanadate to 250mL ultrapure water, heat to 55°C, and keep stirring at 300 rpm until dissolved, then add 5mmol (660.28mg) diammonium hydrogen phosphate, Heat to 65°C and keep stirring at 600 rpm until dissolved, finally add 0.05mmol (400mg) polyvinylpyrrolidone, heat to 70°C, and keep stirring at 400 rpm until dissolved to obtain the precursor solution;

[0048] (2) Spray-dry the precursor solution obtained in step (1), wherein the inlet temperature is 210°C and the flow rate of the liquid is 700mL / h to obtain the precursor of vanadium phosphate / carbon material;

[0049] (3) The precursor of the vanadium phosphate / carbon material obtained in step (2) was heated up to 800°C at a rate of 3°C / min under high-purity helium gas, and kept for 6 hours to obtain a hollow spherical lithium-ion battery negative electrode material vanadium phosphate / carbon.

[0050] After testing, the XRD peaks of the vanadium phosphate / carbon anode material f...

Embodiment 3

[0058] (1) Add 30mmol (3509.4mg) ammonium metavanadate to 600mL ultrapure water, heat to 45°C, and keep stirring at 280 rpm until dissolved, then add 30mmol (3450.9mg) ammonium dihydrogen phosphate, Heat to 65°C and keep stirring at 350 rpm until dissolved, finally add 3mmol (1093.35mg) hexadecyltrimethylammonium bromide, heat to 70°C and keep stirring at 400 rpm , until dissolved to obtain a precursor solution;

[0059] (2) Spray-dry the precursor solution obtained in step (1), wherein the inlet temperature is 210°C and the flow rate of the liquid is 500mL / h to obtain the precursor of vanadium phosphate / carbon material;

[0060] (3) The precursor of the vanadium phosphate / carbon material obtained in step (2) was heated up to 700°C at a rate of 3°C / min under high-purity argon, and kept for 16 hours to obtain a hollow spherical lithium-ion battery negative electrode material vanadium phosphate / carbon.

[0061] After testing, the XRD peaks of the vanadium phosphate / carbon ano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com