Magnesium ion doped gradient nickel cobalt lithium manganate anode material and preparation method thereof

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, applied in the field of magnesium ion-doped gradient nickel-cobalt lithium manganese oxide positive electrode materials and its preparation, can solve the problem of fast capacity decay, low capacity, and inability to meet the needs of lithium-ion battery capacity problem, to achieve the effect of high charge and discharge reaction and reversible charge and discharge reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

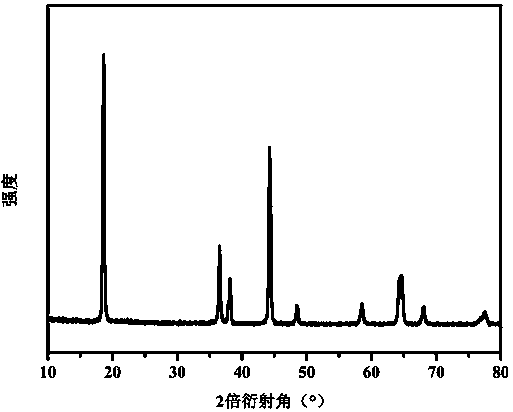

[0062] The chemical formula of the magnesium ion-doped gradient nickel-cobalt lithium manganate positive electrode material is LiNi 0.84 co 0.09 mn 0.05 Mg 0.02 o 2 The nickel content gradually decreases from the center to the surface of the positive electrode material particle, the manganese content gradually increases from the center to the surface of the positive electrode material particle, and the content of cobalt and magnesium is uniformly distributed in the positive electrode material; the magnesium ion The doped graded nickel-cobalt lithium manganate cathode material is spherical particles with an average particle diameter of 7.5 μm.

[0063] Such as figure 1 As shown, the magnesium ion-doped gradient nickel-cobalt lithium manganese oxide positive electrode material in the embodiment of the present invention is a polycrystalline aggregate containing nickel, cobalt, manganese, and magnesium without other impurities.

[0064] Such as figure 2 As shown, the second...

Embodiment 2

[0074] The chemical formula of the magnesium ion-doped gradient nickel-cobalt lithium manganate positive electrode material is LiNi 0.67 co 0.12 mn 0.16 Mg 0.05 o 2 The nickel content gradually decreases from the center to the surface of the positive electrode material particle, the manganese content gradually increases from the center to the surface of the positive electrode material particle, and the content of cobalt and magnesium is uniformly distributed in the positive electrode material; the magnesium ion The doped graded nickel-cobalt lithium manganate cathode material is spherical particles with an average particle diameter of 10.2 μm.

[0075] After testing, the magnesium ion-doped gradient nickel-cobalt lithium manganese oxide positive electrode material in the embodiment of the present invention is a polycrystalline aggregate containing nickel, cobalt, manganese, and magnesium without other impurities.

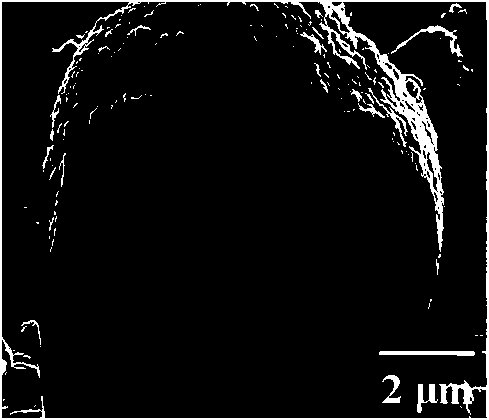

[0076] like Figure 7 As shown, the secondary particle si...

Embodiment 3

[0086] The chemical formula of the magnesium ion-doped gradient nickel-cobalt lithium manganate positive electrode material is LiNi 0.78 co 0.06 mn 0.06 Mg 0.1 o 2 The nickel content gradually decreases from the center to the surface of the positive electrode material particle, the manganese content gradually increases from the center to the surface of the positive electrode material particle, and the content of cobalt and magnesium is uniformly distributed in the positive electrode material; the magnesium ion The doped graded nickel-cobalt lithium manganate cathode material is a spherical particle with an average particle diameter of 6 μm.

[0087] After testing, the magnesium ion-doped gradient nickel-cobalt lithium manganese oxide positive electrode material in the embodiment of the present invention is a polycrystalline aggregate containing nickel, cobalt, manganese, and magnesium without other impurities.

[0088] After testing, the secondary particle size distributio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com