Carbon-based lithium ion battery negative electrode material taking sludge as precursor and preparation of carbon-based lithium ion battery negative electrode material

A technology for ion batteries and anode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of strict requirements on sludge types and components, impossibility of industrial promotion and application, and limited range of sludge selection, so as to improve the reversible capacity And cycle performance, improve lithium intercalation capacity and charge-discharge cycle performance, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

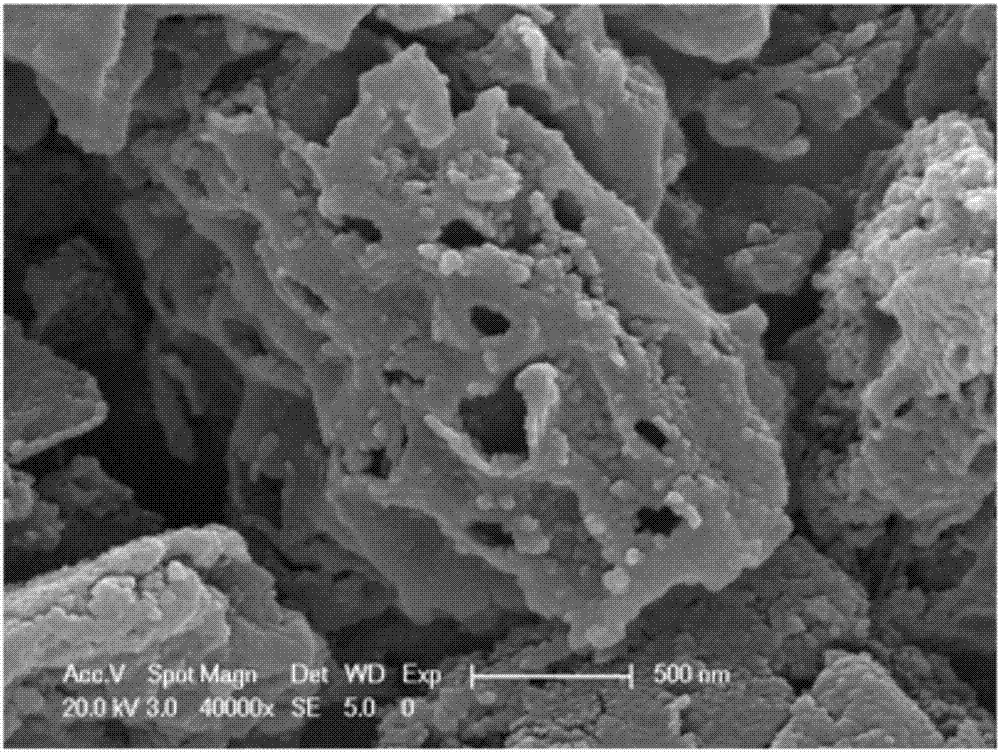

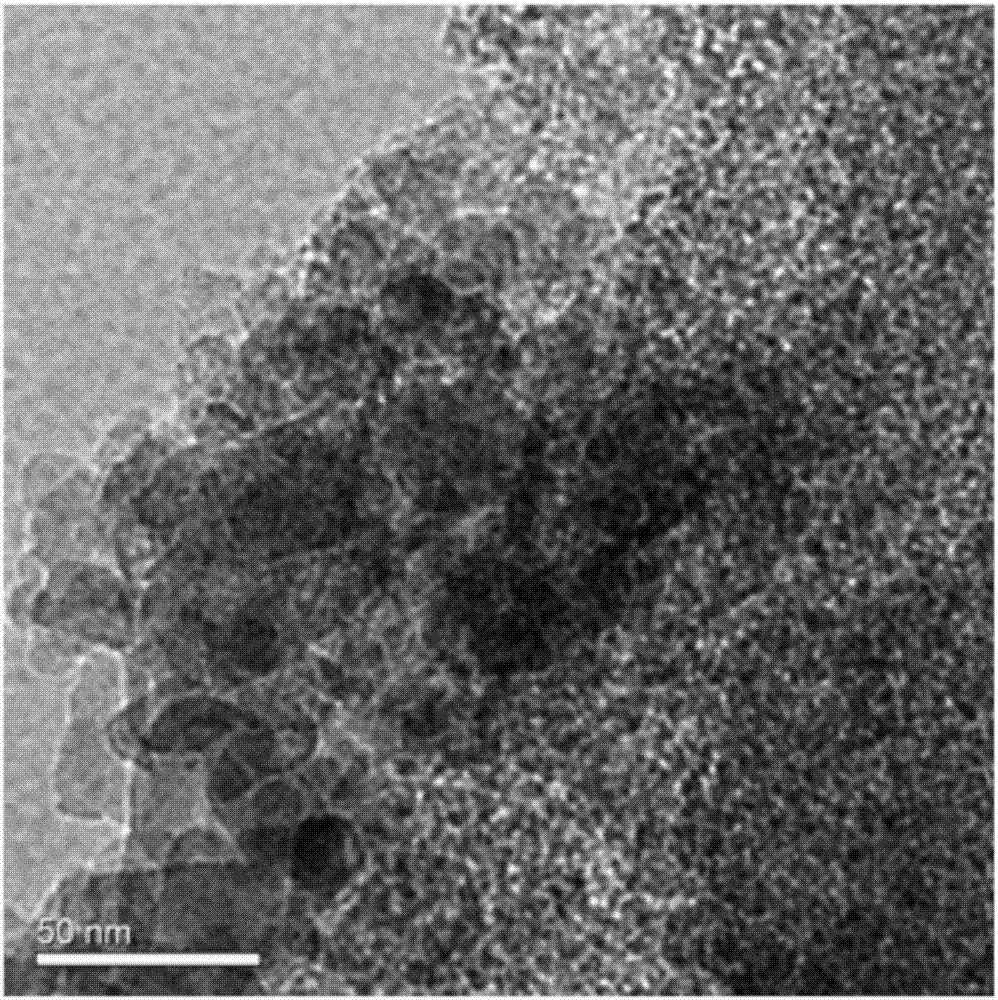

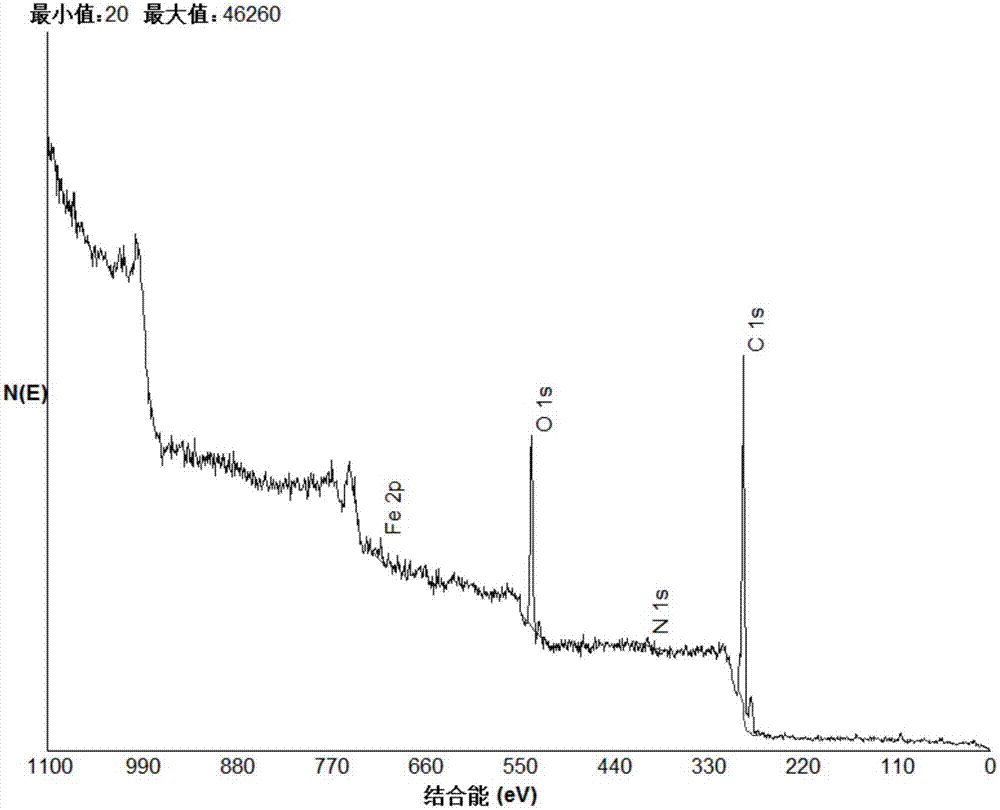

[0042] The primary sludge was lyophilized for 96 hours and ground into powder, placed in a tube furnace, and carbonized at 500°C for 8 hours under nitrogen protection. The obtained carbon material was ground and mixed in a 10% hydrofluoric acid solution for 4 hours. Distilled water was washed and dried; the carbon material obtained by drying was mixed with potassium hydroxide in a ratio of 1:5, then an appropriate amount of distilled water was added, mixed and stirred for 8 hours, dried and ground, and then placed in a tube furnace under nitrogen protection at 800 °C for carbonization again; the obtained carbon The material was soaked in 5% dilute hydrochloric acid for 10 hours, washed with distilled water and dried, and the obtained carbon material was used as the negative electrode material of lithium ion battery.

[0043] The BET test was performed on the carbon-based lithium-ion battery negative electrode material, and the results were compared with the sludge carbon electr...

Embodiment 2

[0053] The dewatered sludge was lyophilized for 48 hours and then ground into powder, placed in a tube furnace, and placed in a tube furnace under nitrogen protection for carbonization at 550 °C for 6 hours. The obtained carbon material was ground into powder, and then placed in 15% hydrogen Mix and stir in the fluoric acid solution for 4 hours, then wash with distilled water until the solution becomes neutral, and dry; mix the dried carbon material and potassium hydroxide in a ratio of 1:4, and add an appropriate amount of distilled water to submerge the carbon material, mix and stir 7h, dried and ground; then put the carbon material in a tube furnace, and carbonized again at 850°C under nitrogen protection; the obtained carbon material was soaked in 4% dilute hydrochloric acid for 10h, washed with distilled water until the solution was neutral, The obtained carbon material is used as a lithium ion battery negative electrode material.

[0054] After testing, the obtained carb...

Embodiment 3

[0056] The digested sludge was lyophilized for 60 hours and ground into powder, which was placed in a tube furnace, and then placed in a tube furnace under nitrogen protection for carbonization at 500°C for 7 hours. The obtained carbon material was ground into powder, and then placed in 20% hydrofluoric acid. Mix and stir in the acid solution for 4 hours, then wash with distilled water until the solution is neutral, and dry; mix the dried carbon material and potassium hydroxide in a ratio of 1:3 and add an appropriate amount of distilled water to submerge the carbon material, mix and stir for 8 hours, Dry and grind; then put the carbon material in a tube furnace, and carbonize again at 800°C under nitrogen protection; soak the obtained carbon material in 6% dilute hydrochloric acid for 12 hours, and wash it with distilled water until the solution is neutral. Carbon materials use them as anode materials for lithium-ion batteries.

[0057] After testing, the obtained carbon mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com