Oscillating head type milling and turning combined machining center

A compound machining center and swing head technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of restricting the processing quality and efficiency of high-end parts, comprehensive compensation processing difficulties, etc., and achieve real-time dynamic solution of multiple errors The effects of comprehensive compensation processing, large torque, and large power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the present invention more clear and understandable, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. All examples.

[0022] In this article, terms such as "left, right, front, and back" are established based on the positional relationship shown in the drawings. Depending on the drawings, the corresponding positional relationship may also change accordingly. It is understood as an absolute limitation of the scope of protection.

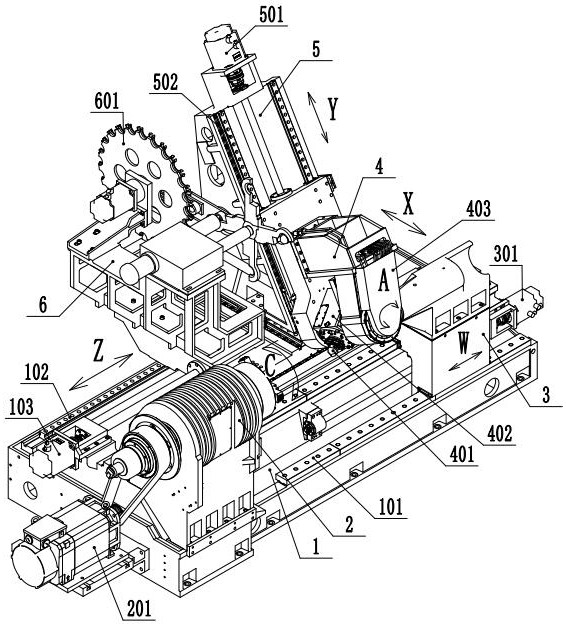

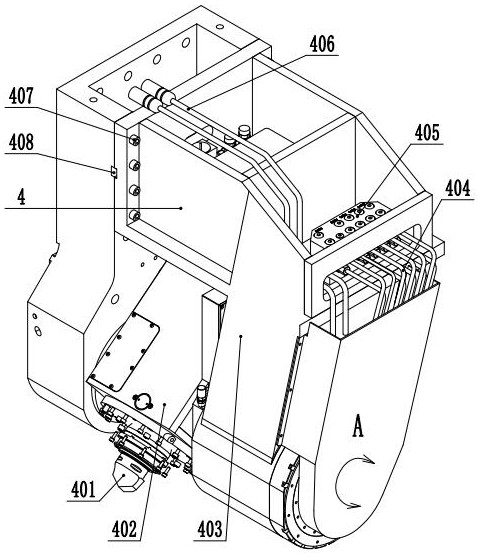

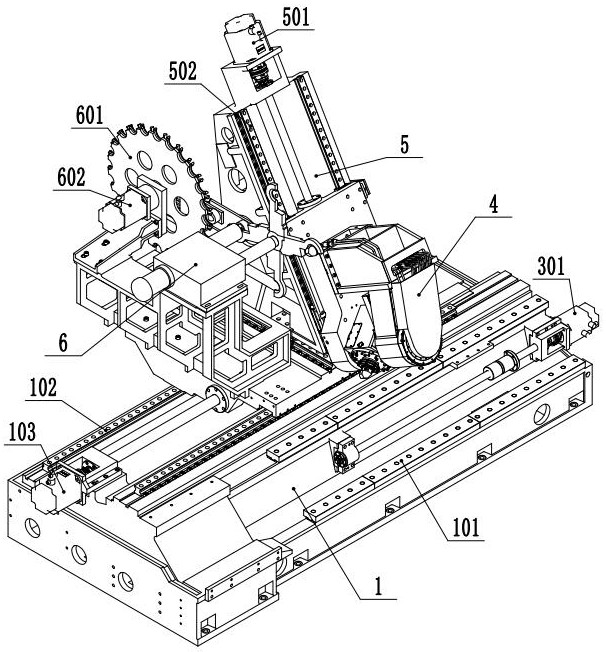

[0023] combine Figure 1-4 , a swing head type milling and turning compound machining center, comprising a bed base 1, a turning head 2, a tailstock 3, a swing head 4, a ram 5 and a tool magazine 6, the turning head 2 is fixedly installed on the bed base 1, and the main shaft Driven by the motor 201, the turning head 2 has interpolation and positioning functions, which is called the C axis; the tailstock 3 is slidingly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com