Lithium-ion battery composite negative electrode material vanadium trioxide/graphene and preparation method

A vanadium trioxide, lithium-ion battery technology, applied in battery electrodes, secondary batteries, electrochemical generators, etc., can solve the problem that the lithium storage and sodium storage properties of nanoparticles cannot be well used, and graphene cannot be fully used. Inhibition, material agglomeration and conductivity, etc., to achieve the effects of stable Coulomb efficiency, good cycle stability and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040](1) Add 3mmol of ammonium metavanadate (350.94mg) into 40mL of a mixed solution of water and ethylene glycol (the volume ratio of water and ethylene glycol is 1:35), heat to 60°C, and turn at 500 rpm , keep stirring until dissolved to obtain solution A;

[0041] (2) Add 80 mg of graphene oxide into the solution A obtained in step (1), and then ultrasonicate for 4 hours at 300W until the graphene oxide is uniformly dispersed to obtain liquid B;

[0042] (3) Heat the liquid B obtained in step (2), conduct a hydrothermal reaction at 180°C for 4 hours, wash with absolute ethanol for 3 times, centrifuge at 8000 rpm, and dry at 80°C for 18 hours to obtain Precursor;

[0043] (4) Heat the precursor obtained in step (3) to 400°C at a speed of 5°C / min in a hydrogen / argon gas mixture (the volume fraction of hydrogen is 5%), and keep it warm for 4 hours to obtain a lithium-ion battery composite negative electrode material Vanadium trioxide / graphene.

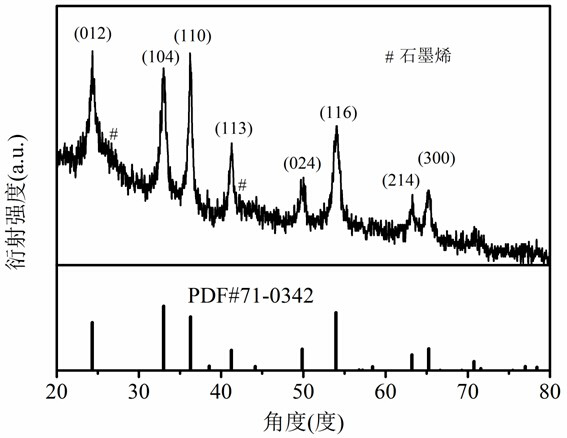

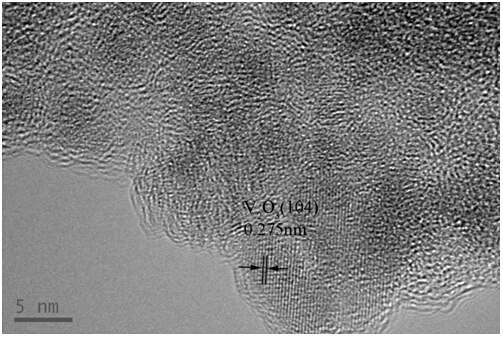

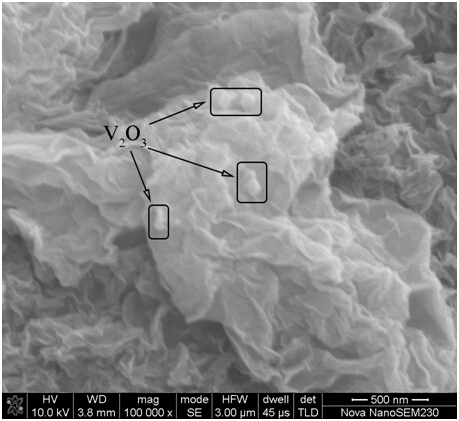

[0044] Such as figure 1 As...

Embodiment 2

[0052] (1) Add 2 mmol of vanadyl acetylacetonate (530.30 mg) into 50 mL of a mixed solution of water and ethylene glycol (the volume ratio of water and ethylene glycol is 1:30), heat to 70 ° C, and turn at 430 rpm , keep stirring until dissolved to obtain solution A;

[0053] (2) Add 53mg of graphene oxide into the solution A obtained in step (1), and then ultrasonicate for 4.5 hours at 350W until the graphene oxide is uniformly dispersed to obtain liquid B;

[0054] (3) Heat the liquid B obtained in step (2), conduct a hydrothermal reaction at 200°C for 10 hours, wash with absolute ethanol for 4 times, centrifuge at 6300 rpm, and dry at 70°C for 12 hours to obtain Precursor;

[0055] (4) Heat the precursor obtained in step (3) to 500°C at a rate of 6°C / min in hydrogen / nitrogen mixed gas (the volume fraction of hydrogen is 6%), and keep it warm for 6 hours to obtain a lithium-ion battery composite negative electrode material Vanadium trioxide / graphene.

[0056] After testin...

Embodiment 3

[0064] (1) Add 6mmol of vanadium acetylacetonate (2089.62mg) into 70mL of a mixed solution of water and ethylene glycol (the volume ratio of water and ethylene glycol is 1:40), heat to 80°C, and at 800 rpm, Stir continuously until dissolved to obtain solution A;

[0065] (2) Add 626.8 mg of graphene oxide into the solution A obtained in step (1), and then ultrasonicate for 5 hours at 500W until the graphene oxide is uniformly dispersed to obtain liquid B;

[0066] (3) Heat the liquid B obtained in step (2), conduct a hydrothermal reaction at 220°C for 10 hours, wash with absolute ethanol 4 times, centrifuge at 6500 rpm, and dry at 75°C for 18.5 hours, get the precursor;

[0067] (4) Heat the precursor obtained in step (3) to 550°C at a speed of 7°C / min in hydrogen / nitrogen mixed gas (the volume fraction of hydrogen is 7%), and keep it warm for 6.5 hours to obtain a lithium-ion battery composite negative electrode Materials Vanadium trioxide / graphene.

[0068] After testing,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com