Layered metal organic phosphate frame sodium ion cathode material and preparation method thereof

A technology of cathode materials and layered metals, applied in the field of sodium ion cathode materials and their preparation, can solve the problems of complex process flow, numerous production steps, poor environmental performance, etc., and achieve good repeatability, strong controllability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0057] The carbon conductive agent used in the embodiment of the present invention is acidified before use. The specific method is: add 0.2g of the carbon conductive agent to 100mL (concentrated sulfuric acid and concentrated nitric acid are mixed at a volume ratio of 3:1) mixed acid, At room temperature, at 300W, carry out ultrasonic dispersion for 4 hours, after cooling to room temperature, add 400mL water to dilute, then use a microporous membrane with a pore size of 0.45μm to carry out suction filtration, wash, repeat the above operation until the washing liquid is neutral, Finally, vacuum-dry at 90°C until constant weight to obtain the acidified carbon conductive agent.

Embodiment 1

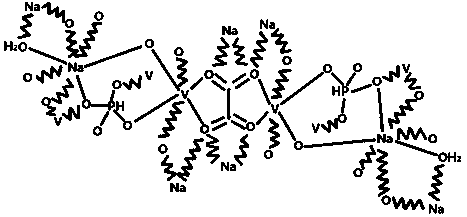

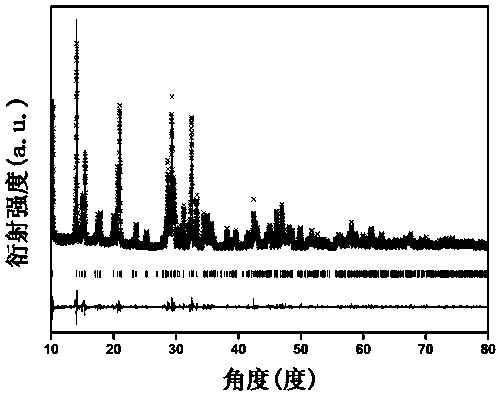

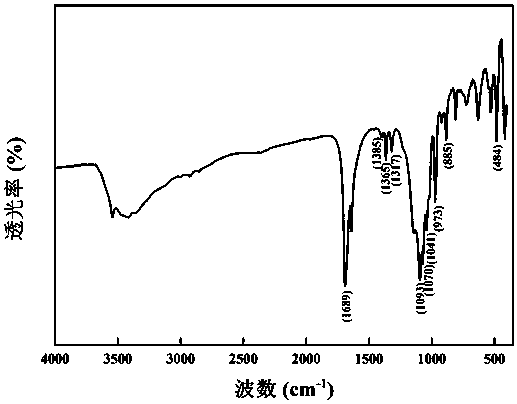

[0059] The layered metal organophosphate framework sodium ion cathode material is a layered material formed by doping acidified carbon nanotubes in the metal organophosphate framework sodium ion cathode material; the metal organophosphate framework sodium ion cathode material The single crystal molecular formula is: C 2 h 10 Na 2 o 16 P 2 V 2 , the molecular structure belongs to the monoclinic structure whose space group is the chiral non-central space group; the unit cell volume of the single crystal molecule is 683.94982 Å 3 , the grain size is 131.6 nm, and the crystallinity is 87.17%; the layered metal organophosphate framework sodium ion positive electrode material is a layered nanosheet structure, and the width of the nanosheet is 1 to 5 μm; the acidified carbon nanotube The doping amount is 5% of the mass of the metal organophosphate framework sodium ion positive electrode material; the particle diameter of the acidified carbon nanotubes doped in the nanosheets is ...

Embodiment 2

[0075] The layered metal organophosphate framework sodium ion cathode material is a layered material formed by doping acidified carbon nanotubes in the metal organophosphate framework sodium ion cathode material; the metal organophosphate framework sodium ion cathode material The single crystal molecular formula is: C 2 h 10 Na 2 o 16 P 2 V 2 , the molecular structure belongs to the monoclinic structure whose space group is the chiral non-central space group; the unit cell volume of the single crystal molecule is 685.6 Å 3 , the grain size is 121.5nm, and the crystallinity is 95%; the sodium ion positive electrode material of the layered metal organophosphate framework is a layered nanosheet structure, and the width of the nanosheet is 5-10 μm; the acidified carbon nanotube The doping amount is 8% of the mass of the metal organophosphate framework sodium ion positive electrode material; the particle diameter of the acidified carbon nanotubes doped in the nanosheets is 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com