Nanometer carbon-lead super capacitor battery

A supercapacitor battery and nanocarbon technology, applied in lead-acid batteries, hybrid capacitor electrodes, battery electrodes, etc., can solve the problems of unsafe lithium batteries and low energy density of lead-acid batteries, and reduce lead pollution and lead consumption. Reduced, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

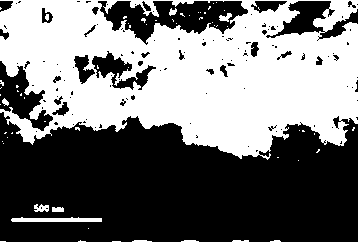

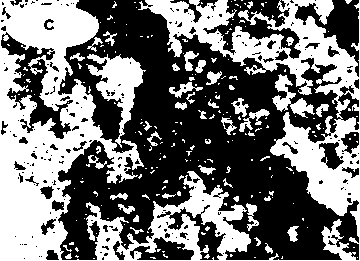

[0030] The carbon nanomaterial and the foamed lead composite material are prepared by an electrodeposition method, and the electrodeposition method includes the following steps:

[0031] 1) Prepare the electrodeposition solution;

[0032] 2) Add carbon nanomaterials to the electrodeposition solution in step 1). At this time, the electrodeposition solution includes lead ions with a concentration of 100g / L, carbon nanomaterials with a concentration of 0.9g / L, and lead ions with a concentration of 30g / L. Fluoroboric acid, boric acid with a concentration of 20g / L and peptone with a concentration of 0.9g / L;

[0033] 3) Conduct electrodeposition, wherein the apparent current density of the electrodeposited cathode is 300A / m 2 , the temperature is 20°C, and after electrodeposition, the composite material of carbon nanometer material and lead foam is obtained.

Embodiment 2

[0035] The other steps are the same, the concentration of each component of the electrodeposition solution adding carbon nanomaterials is: lead ion concentration 150g / L, carbon nanomaterials 1.0g / L, fluoboric acid concentration 30g / L, boric acid concentration 20g / L, peptone concentration 1.0g / L. During the electrodeposition process, the apparent current density of the electrodeposition cathode is 300A / m 2 , temperature 25°C.

Embodiment 3

[0037] The other steps are the same, the concentration of each component of the electrodeposition solution adding carbon nanomaterials is: lead ion concentration 150g / L, carbon nanomaterials 1.0g / L, fluoboric acid concentration 40g / L, boric acid concentration 20g / L, additive peptone concentration 1.0 g / L. During the electrodeposition process, the apparent current density of the electrodeposition cathode is 400A / m 2 , temperature 25°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com