Electromotor energy storage braking system and control method

A technology of energy storage braking and electric motor, which is applied in motor generator control, control system, fluid pressure actuation system components, etc., can solve the problems of large grid interference, small energy storage energy, inconvenient use, etc. Small, large energy storage, reducing the effect of heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

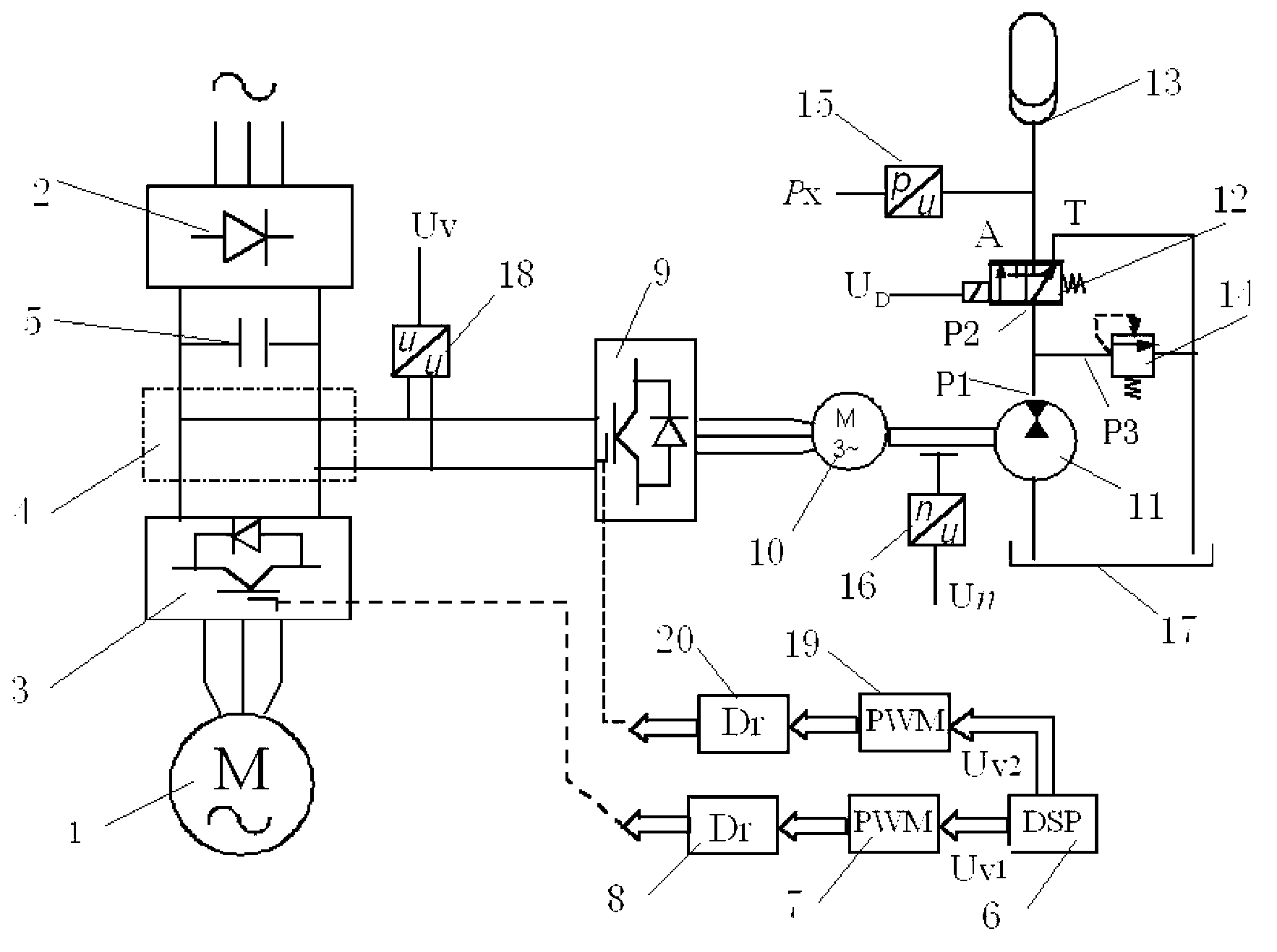

[0023] Such as figure 1 As shown, the motor energy storage braking system in this embodiment includes a main motor 1, a rectifier 2, a main inverter 3, a DC bus 4, a filter capacitor 5, a control computer 6, and the first pulse width signal (PWM) Generator 7 and the 1st driving module 8, wherein: it also comprises motor speed controller 9, electric / generator 10, hydraulic pump / motor 11, two-position three-way control valve 12, hydraulic accumulator 13, safety valve 14 , pressure sensor 15, speed sensor 16, hydraulic oil tank 17, voltage sensor 18, second pulse width signal (PWM) generator 19 and second driving module 20; the oil outlet P1 of the hydraulic pump / motor 11 is connected to the second through the pipeline The oil inlet P2 of the one-position three-way control valve 12 is connected with the oil inlet P3 of the safety valve 14, the oil return port T of the two-position three-way control valve 12 is connected with the hydraulic oil tank 17 through a pipeline, and the t...

Embodiment 2

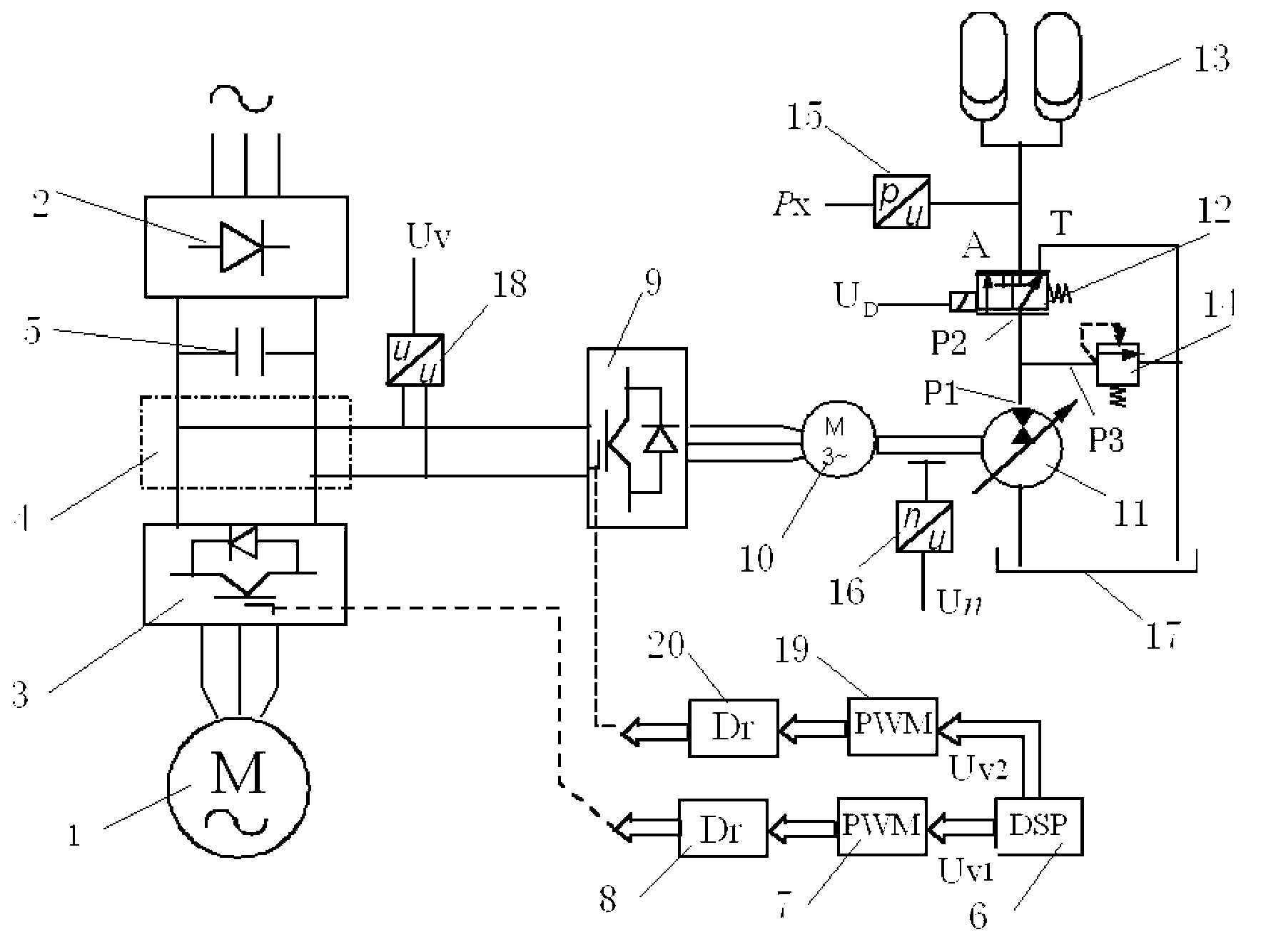

[0034] Such as figure 2 As shown, the motor energy storage braking system and control method in this embodiment are basically the same as the structure and control method in Embodiment 1, the difference is as follows: the quantitative hydraulic pump / motor 11 is electronically controlled variable displacement proportional hydraulic pump / motor instead; the two-position three-way control valve 12 adopts a pilot-operated electro-hydraulic reversing valve; the hydraulic accumulator 13 adopts an accumulator group composed of two accumulators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com