Lithium iron phosphate composite material, its preparation method and application

A technology of lithium iron phosphate and composite materials, which is applied to non-aqueous electrolyte battery electrodes, structural parts, circuits, etc., can solve the problem that the battery cannot be quickly charged and discharged, and achieve the effect of improving electrical conductivity and rapid charging and discharging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

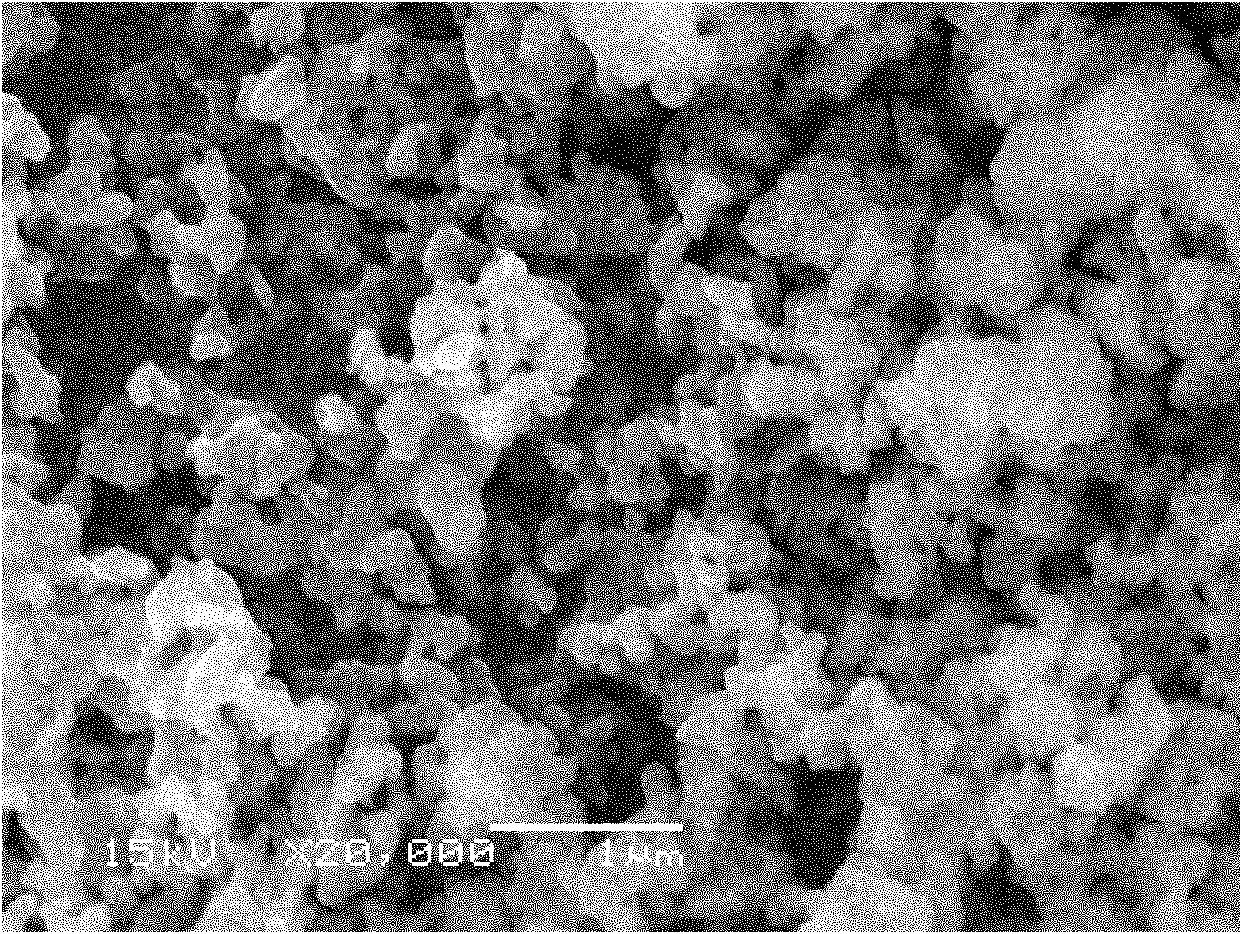

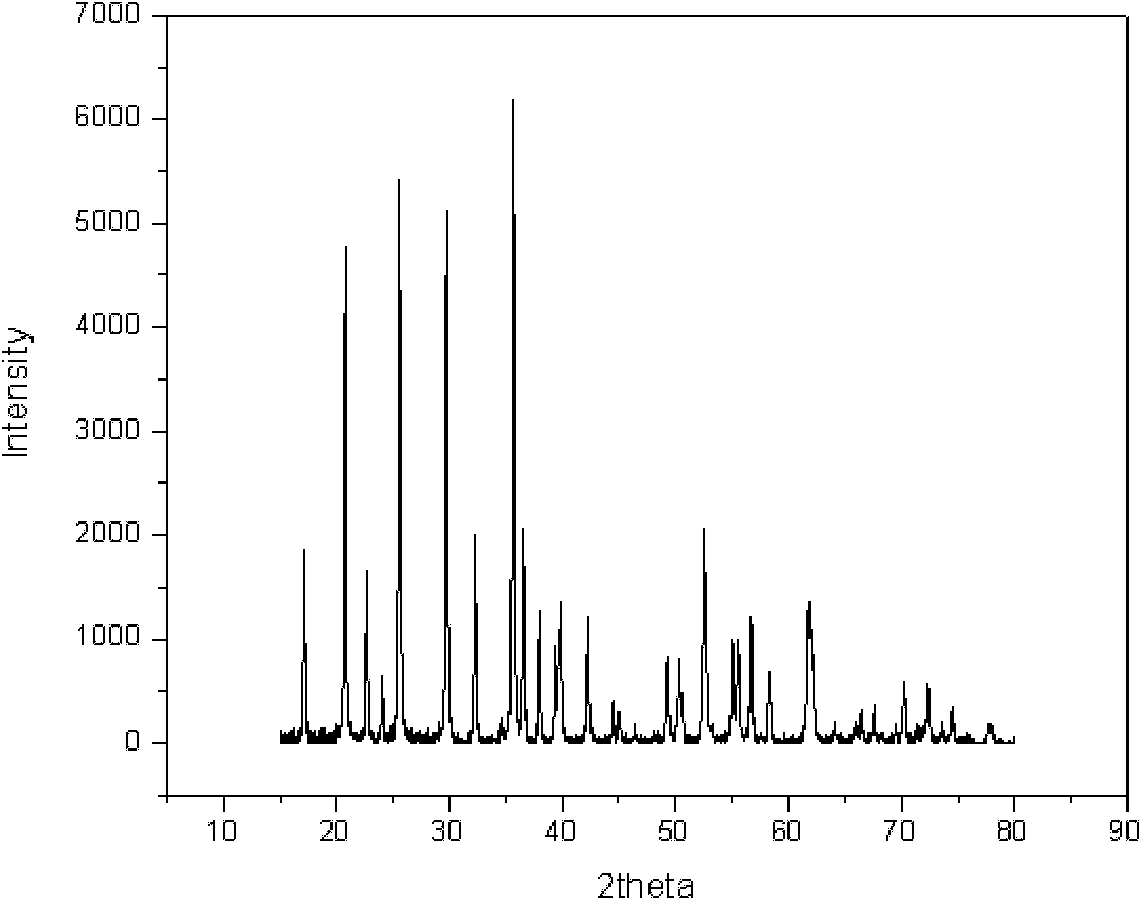

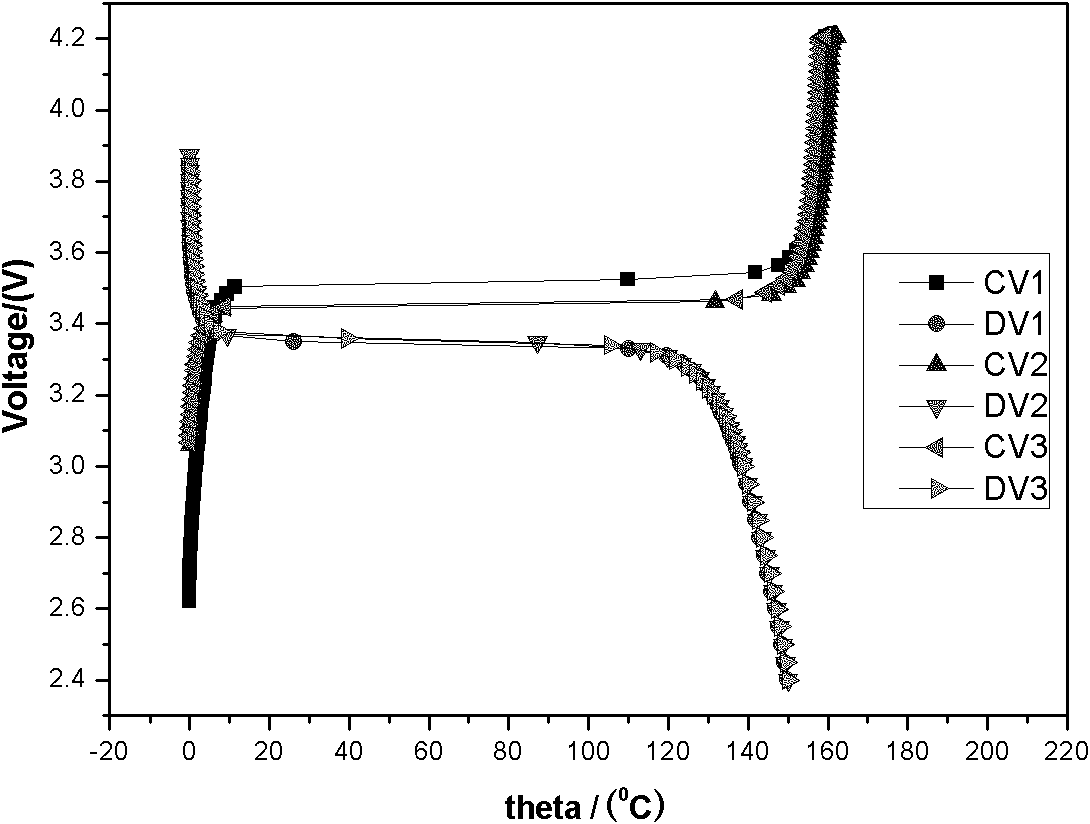

Image

Examples

preparation example Construction

[0021] The preparation method of the lithium iron phosphate of the embodiment of the present invention, the specific steps are as follows:

[0022] a) According to the metal M, iron element and phosphorus element molar ratio is x: 1-x: 1, prepare iron salt mixed solution;

[0023] In step a), preparation containing chemical composition is Fe 1-x m x PO 4 solutions of nanoparticles, by containing Fe 3+ The compound or its solution, the compound of metal M ion or its solution, containing PO 4 3- The compound or its solution is prepared by reacting in a solvent.

[0024] The above contains Fe 3+ The compounds include but are not limited to iron oxide, iron sulfate, iron citrate, and can also be composed of Fe 2+ Compounds such as ferric oxide, ferrous sulfate, ammonium ferrous sulfate, ammonium ferrous phosphate, ferrous phosphate, ferrous citrate, ferrous oxide, etc. are obtained by oxidation containing Fe 3+ There is no limitation on the type of oxidant used, preferably...

Embodiment 1

[0046] Chemical composition is LiFe 0.8 Cr 0.2 PO 4 The preparation method of lithium iron phosphate composite material, concrete steps are as follows

[0047] 1) add ferric nitrate, 85% phosphoric acid, chromium nitrate in aqueous solution, wherein the ratio of the molar number of P and the total molar number of Fe and Cr is 1: 1, ferric nitrate concentration is 2mol / L, chromium nitrate and nitric acid The molar ratio of iron is 1:4;

[0048] II) prepare 100ml of aqueous ammonia solution of 6mol / L;

[0049] III) The deionized water of 50ml is in the beaker and the aniline monomer of 8g is added, under the condition of stirring (500rpm / min) with peristaltic pump continuously simultaneously above-mentioned I) obtains solution input and fills in the solution of aniline monomer, with The pH value of the above-mentioned ammonia solution is controlled to be 2.0 in the reaction system, reacted at 50°C for 2 hours, controlled the flow rate of the peristaltic pump to 0.45ml / min, s...

Embodiment 2

[0060] Chemical composition is LiFe 0.7 Cr 0.3 PO 4 The preparation method of lithium iron phosphate composite material, concrete steps are as follows

[0061] 1) add ferric nitrate, chromium nitrate in aqueous solution, ferric nitrate concentration is 2mol / L, and the mol ratio of chromium nitrate and ferric nitrate is 3: 7;

[0062] II) prepare 100ml of aqueous ammonia solution of 3mol / L;

[0063] III) 50ml of deionized water is added to a beaker and 8g of aniline monomer and ammonium dihydrogen phosphate (the total molar ratio of P to iron and chromium is 1:1), under stirring conditions (500rpm / min) with The peristaltic pump continuously feeds the solution obtained in the above I) into the solution of solution III) at the same time, controls the pH value of the reaction system to 4.0 with the above ammonia solution, reacts at 50°C for 2 hours, and controls the flow rate of the peristaltic pump to 0.45ml / min , after the solution was finished, continue to stir for 2 hours, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com