Rare earth doped lithium titanate electrode material and preparation method thereof

A technology of rare earth doping and lithium titanate, which is applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of low lithium ion diffusion coefficient and electronic conductivity, limit fast charge and discharge performance, etc., and achieve good cycle stability, Good fast charge and discharge ability, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

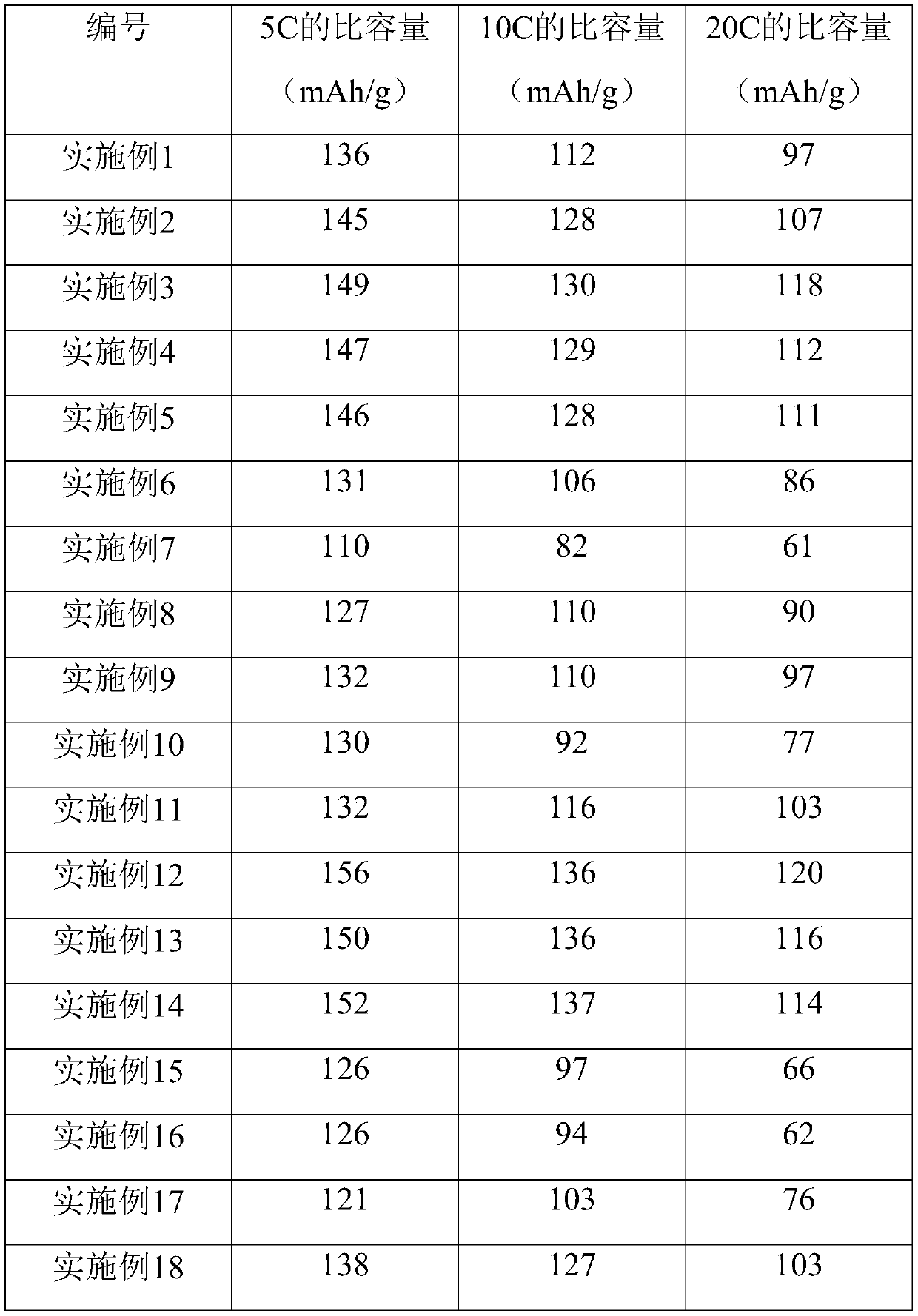

Embodiment 1

[0025] Step 1) Titanium dioxide, lithium carbonate, lanthanum nitrate, and glucose are mixed in ethanol in proportion, and ball milled to prepare slurry; wherein, the mass ratio of glucose to titanium dioxide is 1:10, and the molar ratio of lanthanum nitrate to titanium dioxide is 1:499;

[0026] Step 2) drying the slurry in an oven at 80° C. for 12 hours to prepare a precursor of lanthanum-doped lithium titanate;

[0027] Step 3) Putting the precursor into a tube furnace, and calcining at 950° C. for 6 hours under the protection of a nitrogen atmosphere to prepare a carbon-coated lanthanum-doped lithium titanate precursor;

[0028] Step 4) The carbon-coated lanthanum-doped lithium titanate precursor is then put into a box furnace and calcined at 600° C. for 2 hours in an air atmosphere to prepare lanthanum-doped lithium titanate.

Embodiment 2

[0030] Other conditions are the same as in Example 1, and the difference from Example 1 is that in step 1), the mass ratio of glucose to titanium dioxide is 2:1.

Embodiment 3

[0032] Other conditions are the same as in Example 1, and the difference from Example 1 is that in step 1), the mass ratio of glucose to titanium dioxide is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com