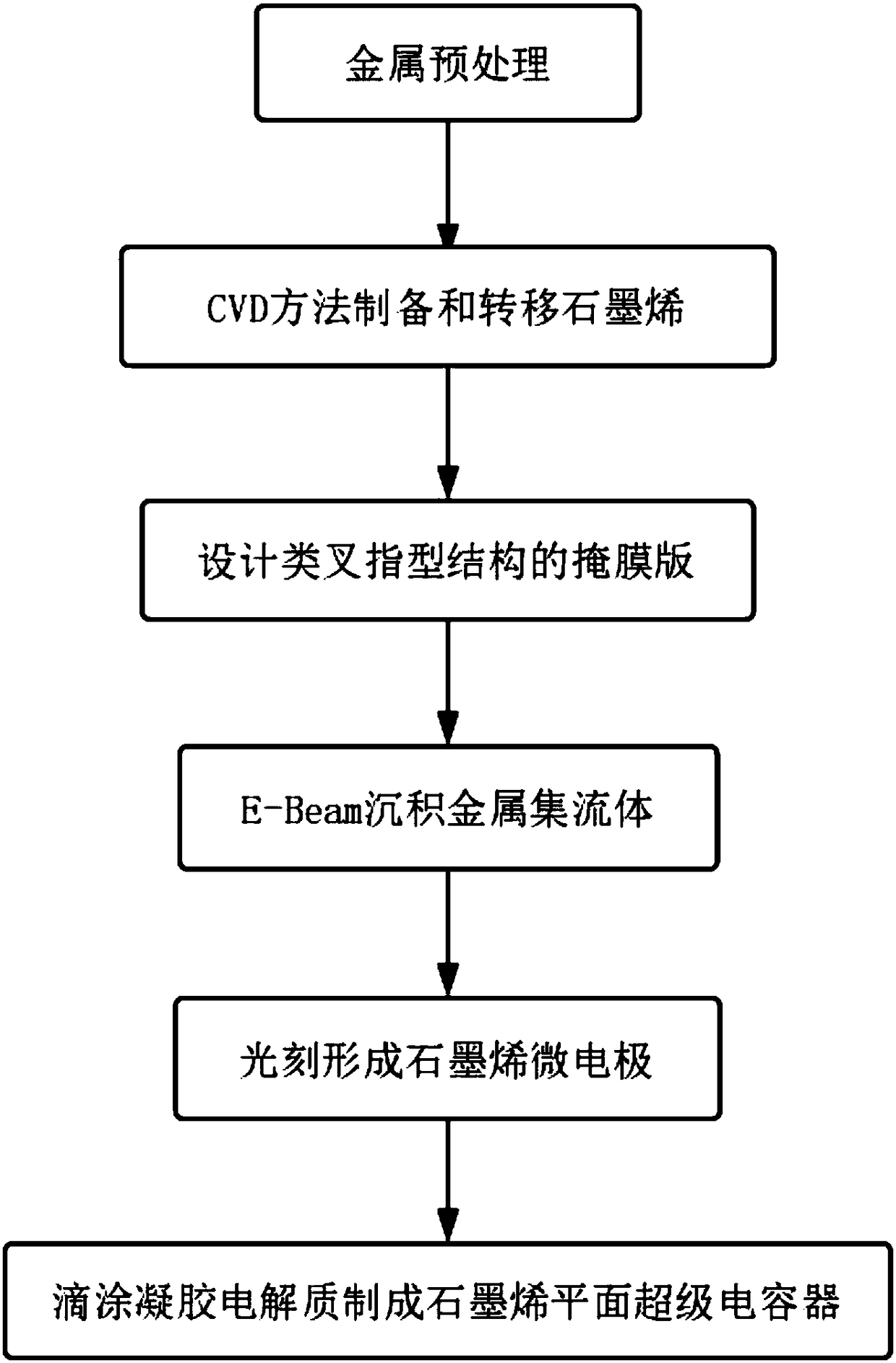

Preparation method of CVD graphene planar miniature supercapacitor

A supercapacitor and graphene technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of not realizing the combination of energy devices and electronic devices, affecting the performance of micro supercapacitors, and the decline in the conductivity of graphene , to achieve the effect of improving fast charge and discharge capacity, reducing volume, and reducing device impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: make the graphene planar micro-supercapacitor based on silicon dioxide substrate.

[0031] Step 1: Carry out substrate pretreatment on metal foamed copper.

[0032] 1a) Select metallic copper foam as the substrate for CVD growth of graphene, and perform a surface pretreatment process, that is, first use a tablet press to thin the foam copper, and then use deionized water in turn to analyze pure acetone and analyze pure ethanol After ultrasonic cleaning several times, dry them for later use;

[0033] 1b) Immerse the thinned copper foam substrate in 0.01M ammonium persulfate solution for 3 minutes to remove oxides on the copper surface, then rinse with deionized water several times and dry.

[0034] Step 2, CVD method prepares and transfers graphene.

[0035] 2a) Put the foamed copper into the tube furnace, evacuate to less than 1Pa, and feed H2 into the furnace with a flow rate of 10 sccm 2 , to heat up to the set temperature of 1030°C;

[0036] 2b) Aft...

Embodiment 2

[0056] Embodiment 2: make the graphene planar miniature supercapacitor based on PET substrate.

[0057] Step 1, base pretreatment is performed on the metal copper foil.

[0058] 1.1) Select metal copper foil as the substrate for CVD growth graphene, and perform surface pretreatment process on it, that is, first press it with a tablet press, and then use deionized water, analytically pure acetone, and analytically pure ethanol for ultrasonic cleaning Blow dry after several times;

[0059] 1.2) Immerse the metal copper foil in a 0.01M ammonium persulfate solution for 3 minutes to remove oxides on the surface of the metal copper, and then rinse the sample several times with deionized water and dry it.

[0060] Step 2, prepare and transfer graphene by CVD method.

[0061] 2.1) Put the pretreated copper foil into the tube furnace, evacuate to less than 1Pa, and feed H2 into the furnace with a flow rate of 50 sccm 2 , to heat up to the set temperature of 1050°C;

[0062] 2.2) Af...

Embodiment 3

[0082] Embodiment 3: making a graphene planar micro-supercapacitor based on a silicon wafer substrate.

[0083] In step A, substrate pretreatment is performed on the nickel foam.

[0084] Select foamed nickel as the substrate for CVD growth graphene, and carry out surface pretreatment process, that is, first use a tablet press to thin the foamed nickel, and then use deionized water, analytically pure acetone, and analytically pure ethanol for ultrasonic cleaning. After several times, dry it for later use; then soak the thinned nickel foam in 0.01M ammonium persulfate solution for 3 minutes to remove oxides on the copper surface, and then rinse the sample with deionized water several times and dry it.

[0085] Step B, preparing and transferring graphene by CVD method.

[0086] In the first step, put the nickel foam into the tube furnace, evacuate to below 1Pa, and feed into the furnace with a flow rate of 20 sccm of H 2 , heat up to the set temperature of 950°C; when the set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com