Lithium iron phosphate/graphene composite lithium battery positive electrode material with porous structure

A graphene composite and lithium iron phosphate technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of poor rate performance and insignificant improvement in electrochemical performance, and achieve excellent electrical conductivity and a wide range of raw material options Broad, effect-enhancing magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

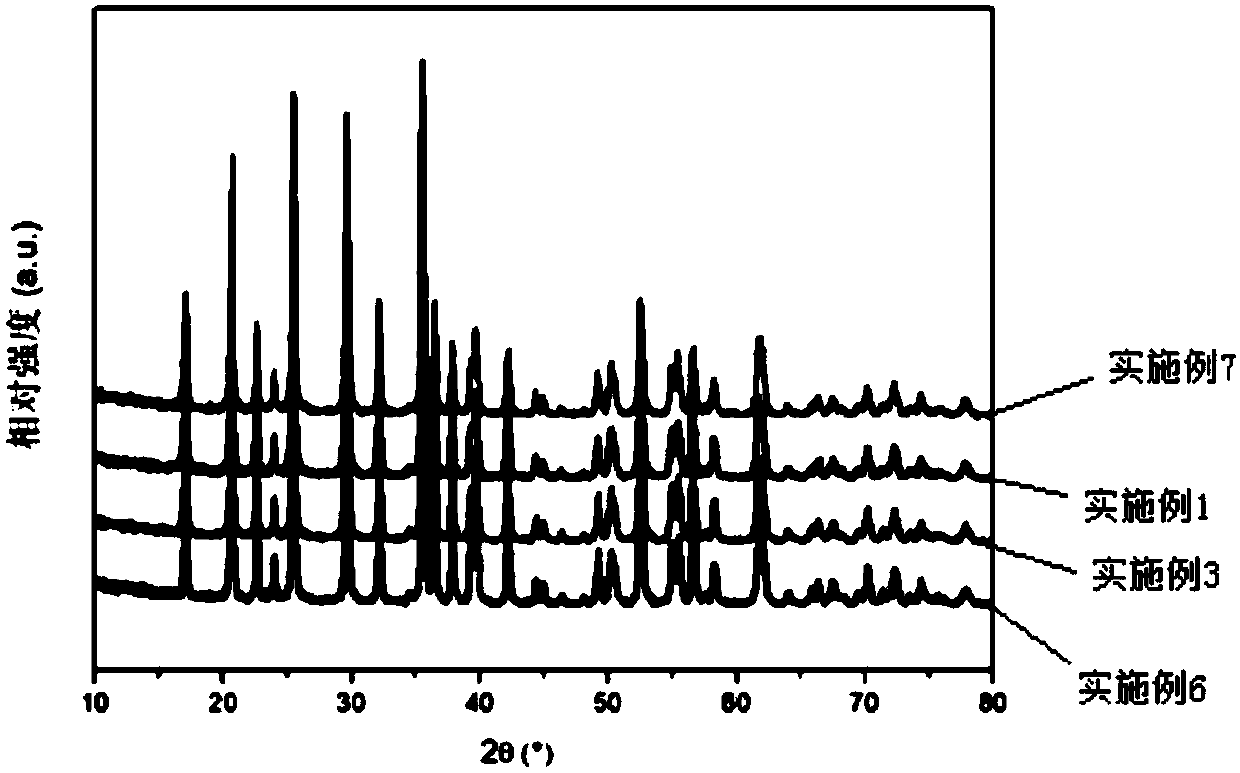

Embodiment 1

[0026] This embodiment provides a lithium iron phosphate / graphene composite lithium battery positive electrode material with a porous structure, the positive electrode material has a core-shell structure, wherein the material of the core structure is lithium iron phosphate, the material of the shell structure is graphene, and A pore structure is formed on the graphene, the pore size of the pore structure is 5nm-100nm, and the specific surface area of the positive electrode material is 180㎡ / g.

[0027] Wherein, the particle size of lithium iron phosphate is 1 μm-5 μm, and the thickness of graphene is 10 nm-100 nm.

[0028] The preparation method of the cathode material at least includes the following steps:

[0029] In the first step, mix deionized water with lithium carbonate, iron phosphate, and sucrose and stir thoroughly to obtain mixture A; wherein, the molar ratio of lithium in lithium carbonate and iron in iron phosphate is 1:1, and in mixture A, The concentration of ...

Embodiment 2

[0037] This embodiment provides a lithium iron phosphate / graphene composite lithium battery positive electrode material with a porous structure, the positive electrode material has a core-shell structure, wherein the material of the core structure is lithium iron phosphate, the material of the shell structure is graphene, and A pore structure is formed on the graphene, the pore size of the pore structure is 5nm-100nm, and the specific surface area of the positive electrode material is 130㎡ / g.

[0038] Wherein, the particle size of lithium iron phosphate is 1 μm-5 μm, and the thickness of graphene is 10 nm-100 nm.

[0039] The preparation method of the cathode material at least includes the following steps:

[0040] In the first step, mix deionized water with lithium acetate, iron phosphate, and sucrose and stir thoroughly to obtain mixture A; wherein, the molar ratio of lithium in lithium acetate to iron in iron phosphate is 1.01:1, and in mixture A, The concentration of li...

Embodiment 3

[0046] This embodiment provides a lithium iron phosphate / graphene composite lithium battery positive electrode material with a porous structure, the positive electrode material has a core-shell structure, wherein the material of the core structure is lithium iron phosphate, the material of the shell structure is graphene, and A pore structure is formed on the graphene, the pore size of the pore structure is 5nm-100nm, and the specific surface area of the positive electrode material is 100m2 / g.

[0047] Wherein, the particle size of lithium iron phosphate is 1 μm-5 μm, and the thickness of graphene is 10 nm-100 nm.

[0048] The preparation method of the cathode material at least includes the following steps:

[0049] In the first step, mix deionized water with lithium citrate, iron phosphate, and sucrose and stir thoroughly to obtain mixture A; wherein, the molar ratio of lithium in lithium citrate and iron in iron phosphate is 0.99:1, and in mixture A Among them, the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com