Method for improving conductivity of zinc oxide negative electrode material applicable to lithium ion battery

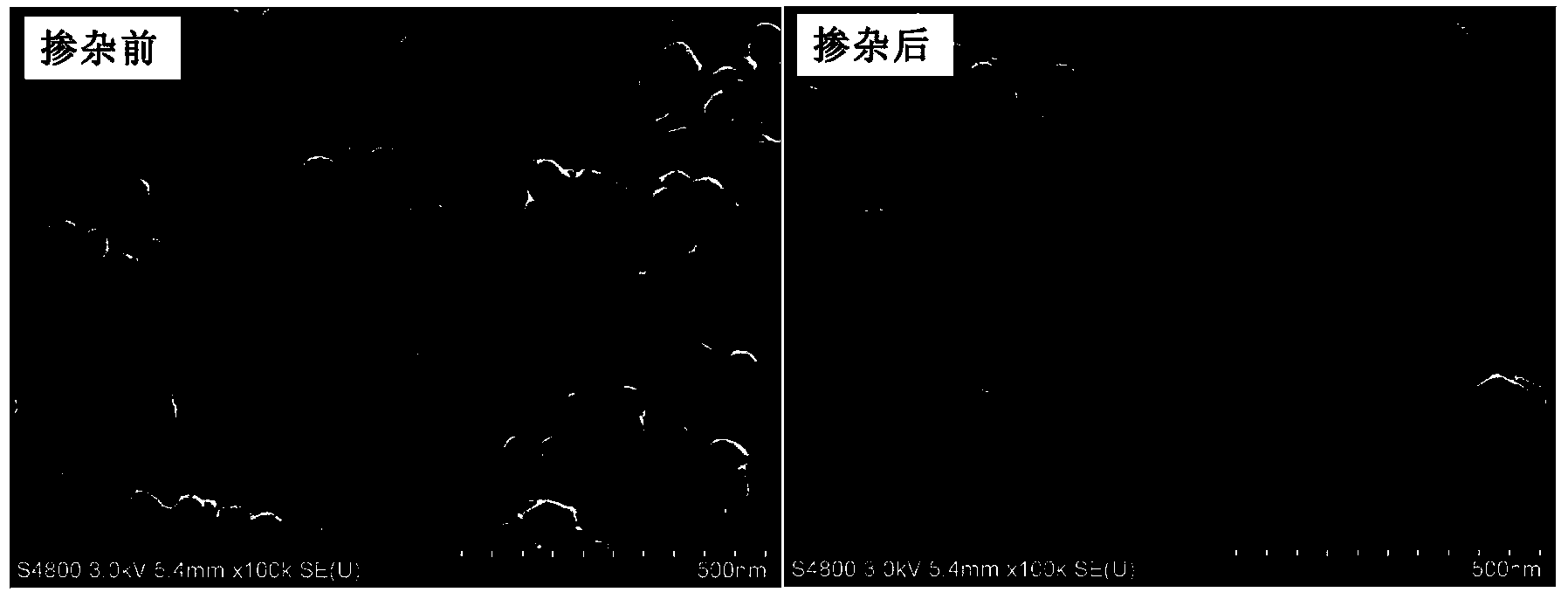

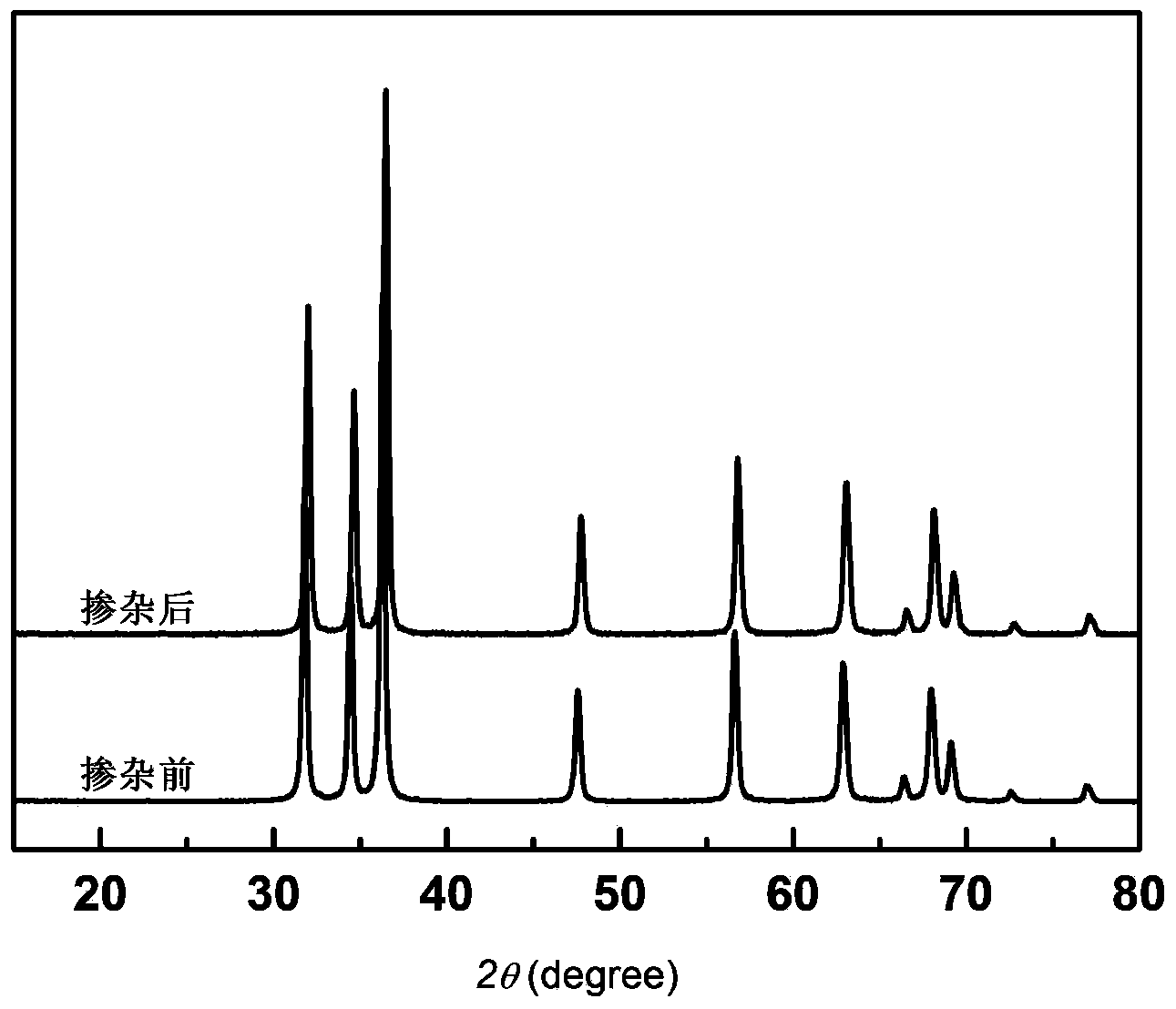

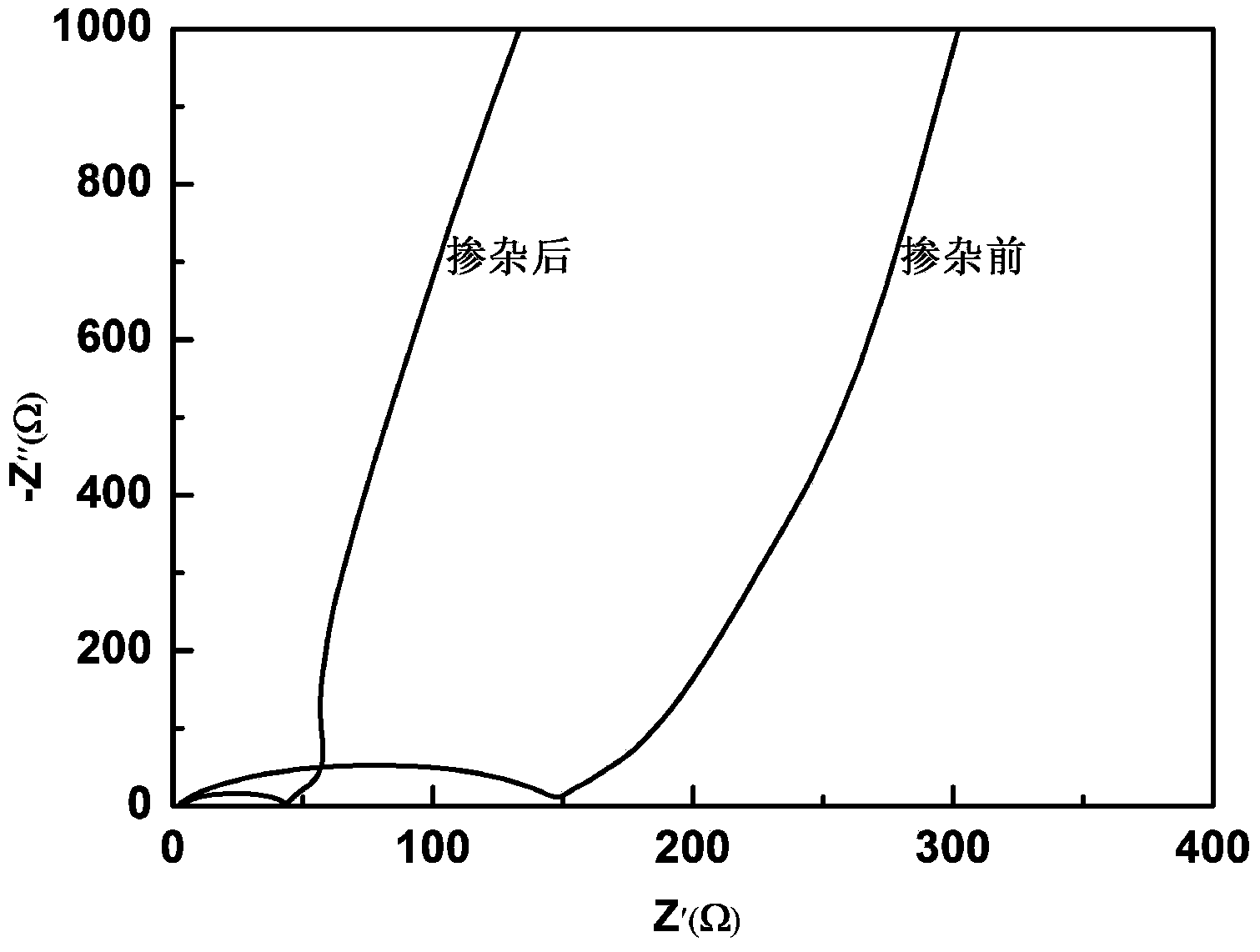

A lithium-ion battery and anode material technology, applied in battery electrodes, batteries, secondary batteries, etc., can solve problems such as poor conductivity, zinc oxide lattice distortion, poor rapid charge and discharge ability, etc., to improve conductivity and production costs Low, improve the effect of volume expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 2.5000gZn(CH 3 CO 2 ) 2 2H 2 O (zinc acetate) and 0.0894gAl (NO 3 ) 3 9H 2 O (aluminum nitrate) was dissolved in 40ml of absolute ethanol, stirred for 30min, transferred to a 50ml hydrothermal kettle, and reacted at 150°C for 12h using the traditional hydrothermal method. After the reaction, it was naturally cooled to room temperature, washed with water and ethanol three times respectively, and then dried at 90°C to obtain doped Al 3+ zinc oxide anode material.

Embodiment 2

[0038] Weigh 2.5000gZnCl 2 (Zinc chloride) and 0.0994gAl(SO 4 ) 3 (Aluminum sulfate) was dissolved in 40ml of absolute ethanol, stirred for 30min, transferred to a 50ml hydrothermal kettle, and reacted at 120°C for 2h by microwave hydrothermal method. After the reaction was completed, it was naturally cooled to room temperature, washed with water and ethanol three times respectively, and then dried at 90°C to obtain doped Al 3+ zinc oxide anode material.

Embodiment 3

[0040] Weigh 2.5000gZn(CH 3 CO 2 ) 2 2H 2 O (zinc acetate) and 0.1894gGa (NO 3 ) 3 (Gallium nitrate) was dissolved in 40ml of absolute ethanol, stirred for 30min, transferred to a 50ml hydrothermal kettle, and reacted at 90°C for 15h using a homogeneous hydrothermal method. After the reaction, it was naturally cooled to room temperature, washed with water and ethanol three times respectively, and then dried at 90°C to obtain doped Ga 3+ zinc oxide anode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com