Germanium dioxide/graphene composite and preparation method thereof

A germanium dioxide and composite material technology, applied in secondary batteries, electrochemical generators, electrical components, etc., can solve the problems of low product purity, environmental pollution, complicated steps, etc., and achieve high purity, no environmental pollution, raw materials, etc. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A preparation method of germanium dioxide / graphene composite material, the steps are as follows:

[0024] (1) Add 0.1 g of commercial germanium dioxide powder and 0.03 g of graphene oxide (GO) into 30 ml of distilled water, and magnetically stir the solution for 50 minutes, so that both germanium dioxide and graphene oxide are completely dissolved in distilled water;

[0025] (2) Transfer the obtained solution into a watch glass, put the watch glass into an electric heating constant temperature blast drying oven, keep a constant temperature of 35°C until the water evaporates completely;

[0026] (3) Calcining the black powder obtained after drying in step (2) at 300° C. for 1.5 hours in an air atmosphere, and finally obtaining a germanium dioxide / graphene composite material.

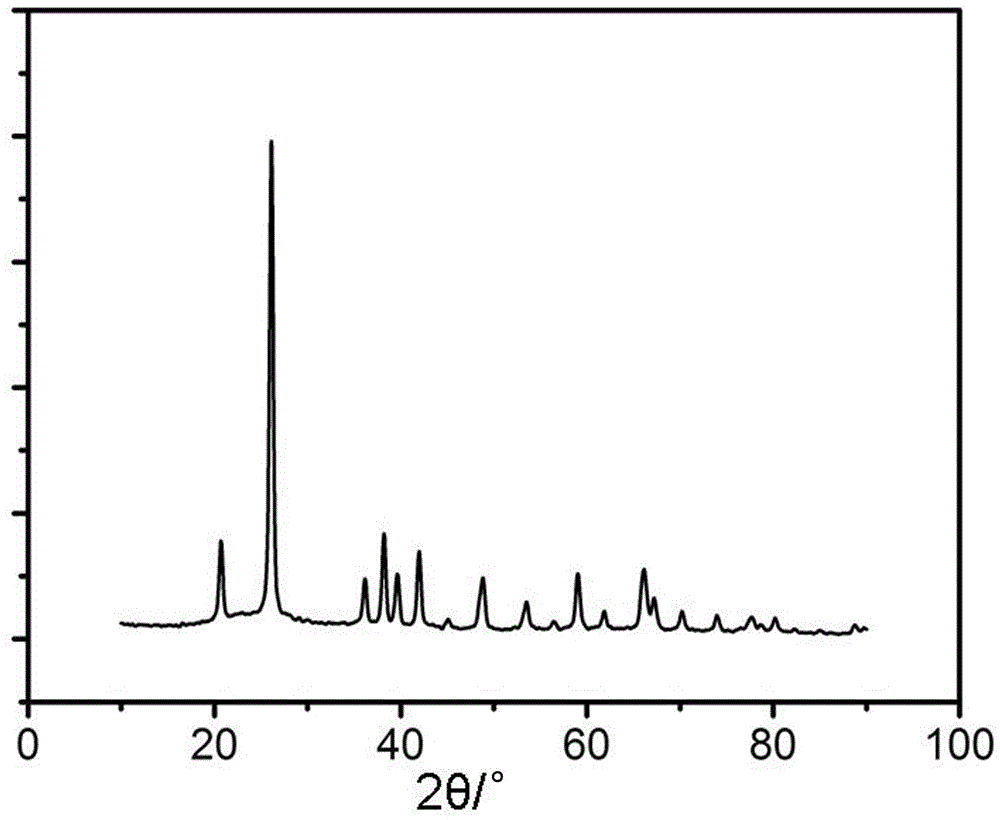

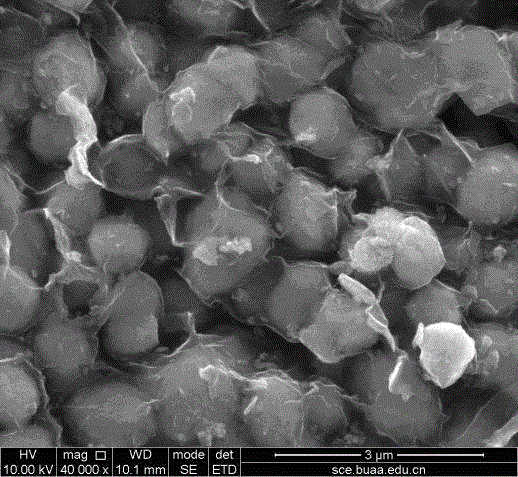

[0027] Such as figure 1 As shown, the X-ray powder diffraction of the product obtained in this example shows that the product is germanium dioxide in the hexagonal phase, corresponding to the JCP...

Embodiment 2

[0030] A preparation method of germanium dioxide / graphene composite material, the steps are as follows:

[0031] (1) Add 0.5 g of commercial germanium dioxide powder and 0.05 g of graphene oxide (GO) into 120 ml of distilled water, and magnetically stir the solution for 30 minutes, so that both germanium dioxide and graphene oxide are completely dissolved in distilled water;

[0032] (2) Transfer the obtained solution into a watch glass, put the watch glass into an electric heating constant temperature blast drying oven, and keep a constant temperature of 25°C until the water evaporates completely;

[0033] (3) Calcining the black powder obtained after drying in step (2) at 300° C. for 2.5 hours in an air atmosphere, and finally obtaining a germanium dioxide / graphene composite material. The resulting product has a purity of 100%.

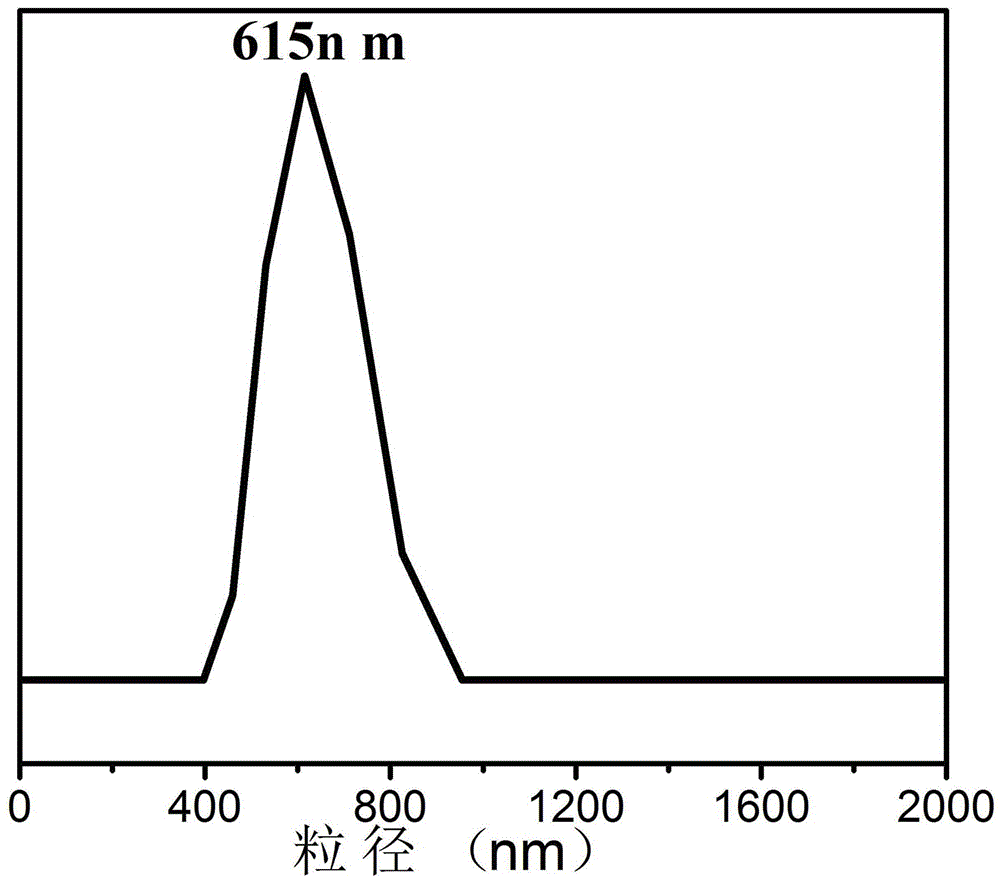

[0034] The germanium dioxide / graphene composite material prepared in this example was used as the negative electrode material of lithium ion batte...

Embodiment 3

[0036] A preparation method of germanium dioxide / graphene composite material, the steps are as follows:

[0037] (1) Add 0.8 g of commercial germanium dioxide powder and 1.0 g of graphene oxide (GO) into 200 ml of distilled water, and magnetically stir the solution for 60 minutes, so that both germanium dioxide and graphene oxide are completely dissolved in distilled water;

[0038](2) Transfer the obtained solution into a watch glass, put the watch glass into an electric heating constant temperature blast drying oven, and keep a constant temperature of 40°C until the water evaporates completely;

[0039] (3) Calcining the black powder obtained after drying in step (2) at 250° C. for 1 hour in an air atmosphere, and finally obtaining a germanium dioxide / graphene composite material. The resulting product has a purity of 100%.

[0040] The germanium dioxide / graphene composite material prepared in this example was used as the negative electrode material of lithium ion battery, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com