Carbon-coated titanium sodium phosphate composite material and prepared sodium ion battery

A carbon-coated technology for sodium titanium phosphate and sodium ion batteries, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as side reactions, poor cycle stability, poor electronic conductivity, etc. Good cycle stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mix sodium dihydrogen phosphate monohydrate, titanium dioxide, and diammonium hydrogen phosphate evenly according to the molar ratio of 1:2:2, add 10% conductive carbon black, use ethanol as the organic solvent, and the mass ratio of ball to material is 10:1. 1000r / min, ball milled for 2 hours, and then dried at 80°C. The obtained material was placed in an atmosphere furnace, first sintered at 400°C for 5 hours at a rate of 5°C / min in an argon atmosphere, then heated to 900°C for 10 hours, and further mechanically crushed to obtain NaTi 2 (PO 4 ) 3 / C Composite.

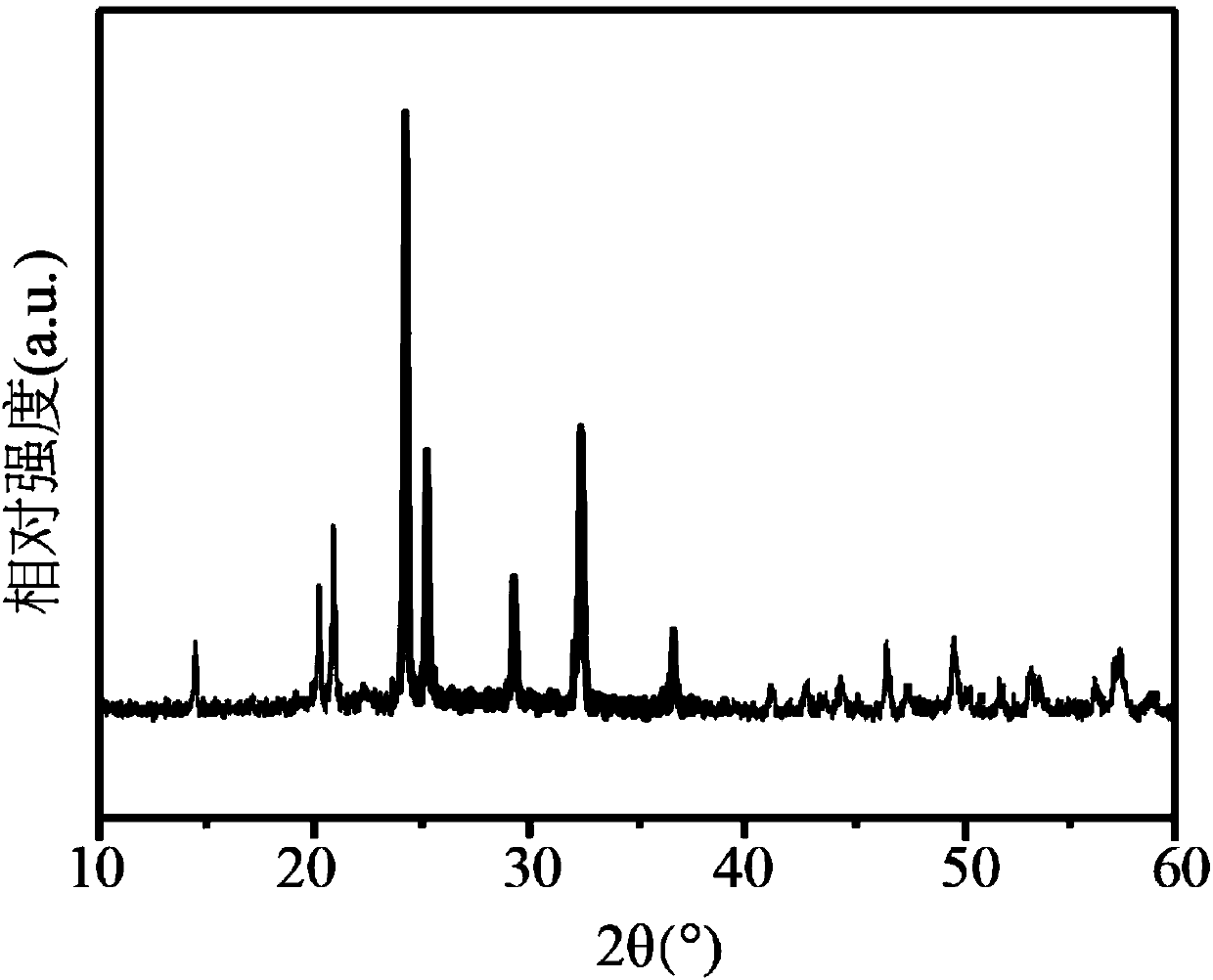

[0032] NaTi 2 (PO 4 ) 3 The crystal structure of / C composite material is good, and the R3c space structure is well maintained, indicating that the crystal structure of sodium titanium phosphate has not been changed during the coating process. ( figure 1 )

[0033] NaTi 2 (PO 4 ) 3 The main particle size of the / C composite material is 1-3μm and 50-500nm, the crystal form is good, and the distributi...

Embodiment 2

[0036] Mix sodium dihydrogen phosphate dihydrate, titanium dioxide, and ammonium dihydrogen phosphate evenly according to the molar ratio of 1:2:2, add 5% of 1500 mesh graphite, use acetone as the organic solvent, the mass ratio of balls to materials is 50:1, and the speed of the host is 800r / min, ball milled for 5h, and then dried at 80°C. The obtained material was placed in an atmosphere furnace, sintered at 400°C for 5 hours at a rate of 5°C / min in an argon atmosphere, then heated to 900°C for 10 hours, and further mechanically crushed to obtain NaTi 2 (PO 4 ) 3 / C Composite.

[0037] With the NaTi that embodiment 2 prepares 2 (PO 4 ) 3 / C composite material, conductive carbon black and binder PTFE are mixed according to the mass ratio of 80:10:10, slurried with N-methylpyrrolidone, then coated on the treated graphite paper, and dried for 12 hours. Then with 1M NaSO 4 The sodium aqueous solution is used as the electrolyte, and the activated carbon material is used as...

Embodiment 3

[0040] In Example 1, the molar ratio of sodium dihydrogen phosphate monohydrate, titanium dioxide, and diammonium hydrogen phosphate was adjusted to 1:1.7:2, and the rest were the same as in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com