Composite graphite negative electrode material, preparation method and application thereof, and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in the directions of graphite, battery electrodes, secondary batteries, etc., can solve the problems of low rate charge and discharge performance, high production cost, low lithium intercalation capacity, etc. The effect of sheet rebound and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

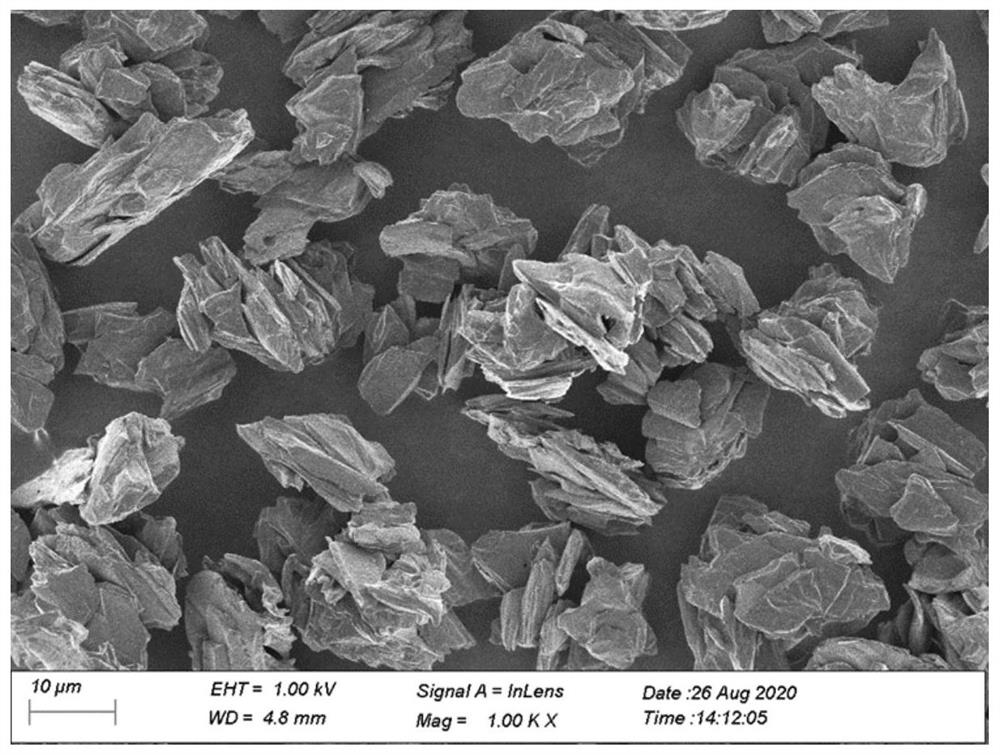

Image

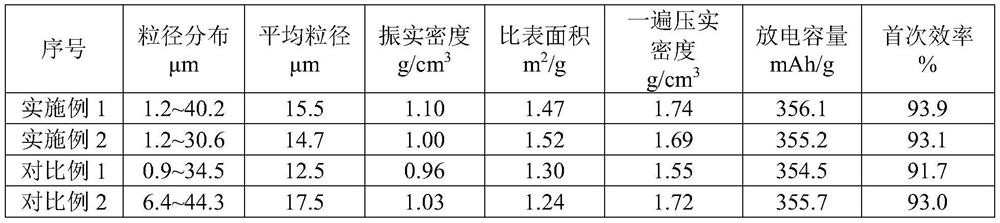

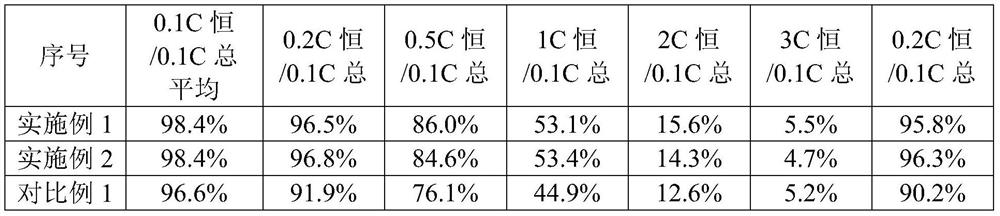

Examples

Embodiment 1

[0074] The preparation method of the composite graphite negative electrode material of the present embodiment, concrete steps are as follows:

[0075] The kiln powder of the needle coke is pulverized by a roller mill. The median particle size D50 of the pulverized material is 9.5 μm, and the fine powder is removed by shaping. At this time, the median particle size D50 of the shaped material is 10.0 μm. The shaped material was graphitized in an Acheson graphitization furnace, the graphitization temperature was 3000°C, and the temperature was kept constant for 32 hours. The graphitized material and petroleum asphalt were mixed in a CDLW-6000 ribbon mixer with a mass ratio of 100:4 for 60 minutes. The frequency of the CDLW-6000 ribbon mixer was 30 Hz, and the petroleum asphalt The median particle size D50 is 3 μm, the softening point is 220°C, and the volatile content is 35%. The above-mentioned mixture is coated with asphalt in a horizontal coating kettle. The horizontal coatin...

Embodiment 2

[0079] The difference between this example and Example 1 lies in that the first particle and the second particle are blended at a mass ratio of 50:50, and other conditions are kept the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com