Graphene-based quasi-solid battery based on printing technology

A solid-state battery and graphene technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of uncontrollable battery shape and difficulty in further thinning the coating thickness of the electrode layer, so as to facilitate rapid transmission and easy wireless Seam connection, reduce the effect of interface impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

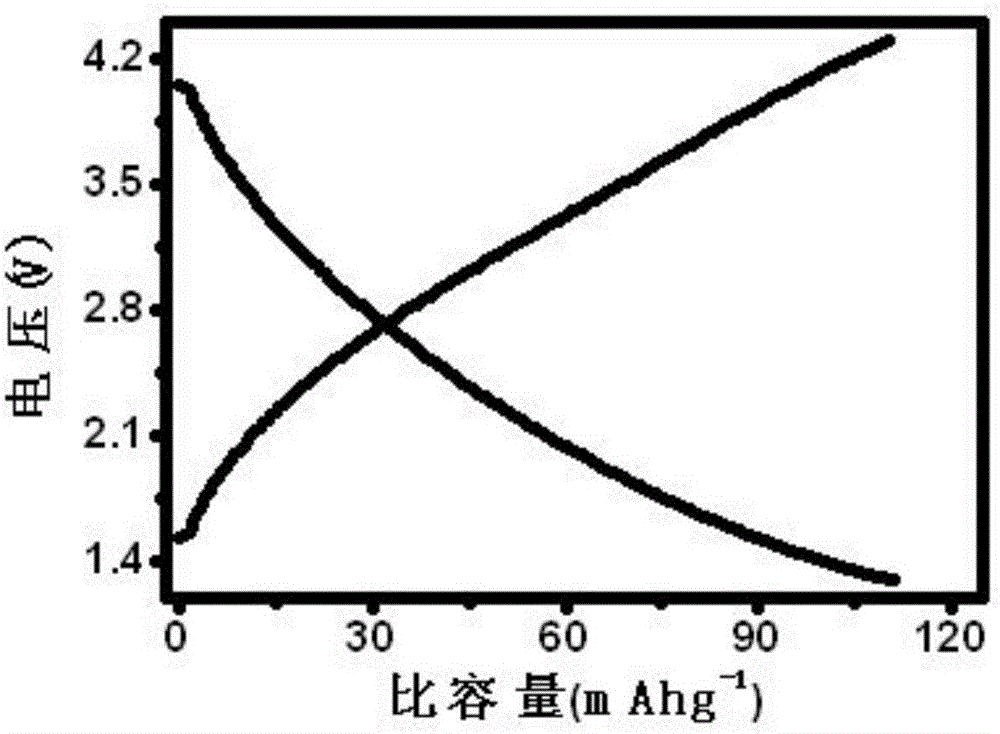

[0030] A graphene benchmark solid-state battery based on printing technology, the functionalized graphene material is prepared into positive ink, and the positive electrode is printed on the positive current collector by inkjet printing; the solid electrolyte membrane is obtained by coating; The negative electrode material is pressed on the negative electrode current collector to obtain the negative electrode; the liquid electrolyte is sprayed on the surface of the positive electrode, and the solid electrolyte membrane and the negative electrode are combined successively to obtain a quasi-solid-state battery.

[0031] The specific implementation process of graphene benchmark solid-state battery based on printing technology:

[0032] 1. Positive electrode preparation:

[0033] a) Mix the functionalized graphene material, conductive agent (carbon nanotubes), and binder (CMC) in a weight ratio of 90:5:5, use pure water as the solvent, stir magnetically for 10 hours, and disperse ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com