Preparation method and application of iron-modified carbon microsphere/carbon nanosheet composite porous carbon based on hydrothermal carbonization of moso bamboos

A technology of hydrothermal carbonization and carbon microspheres, applied in chemical instruments and methods, carbon compounds, hybrid/electric double layer capacitor manufacturing, etc., can solve problems such as promotion, unfavorable electrochemical performance of materials, and destruction of special morphology, and achieve Improve dispersibility and fluidity, benefit large-scale industrial production, and have suitable pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

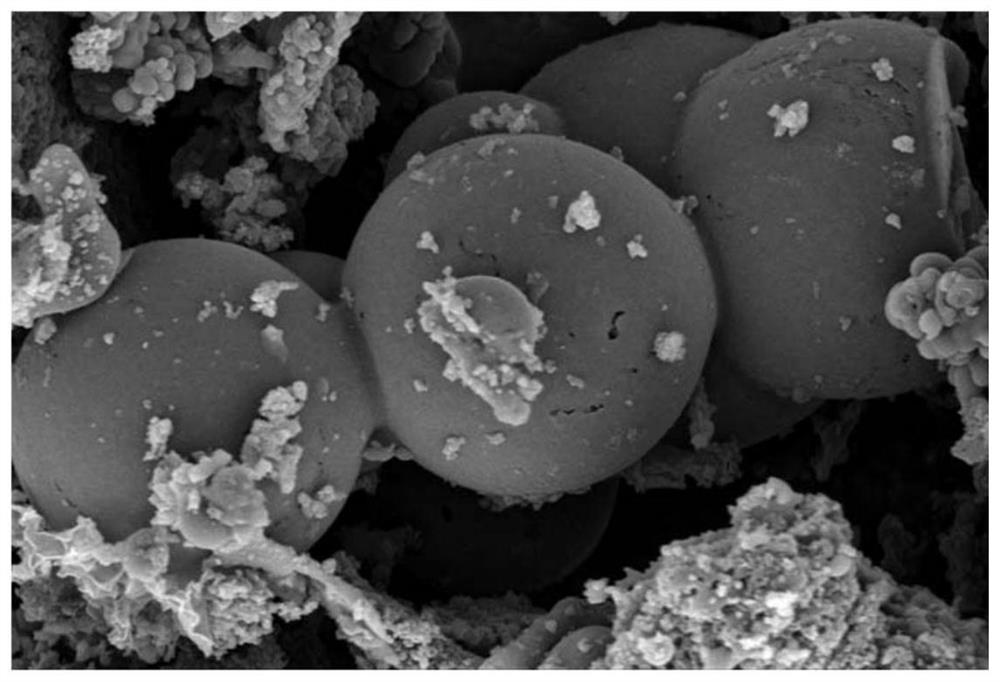

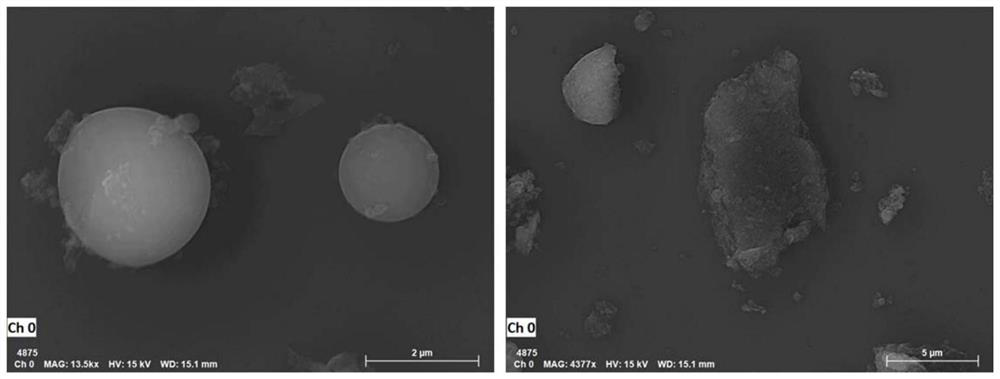

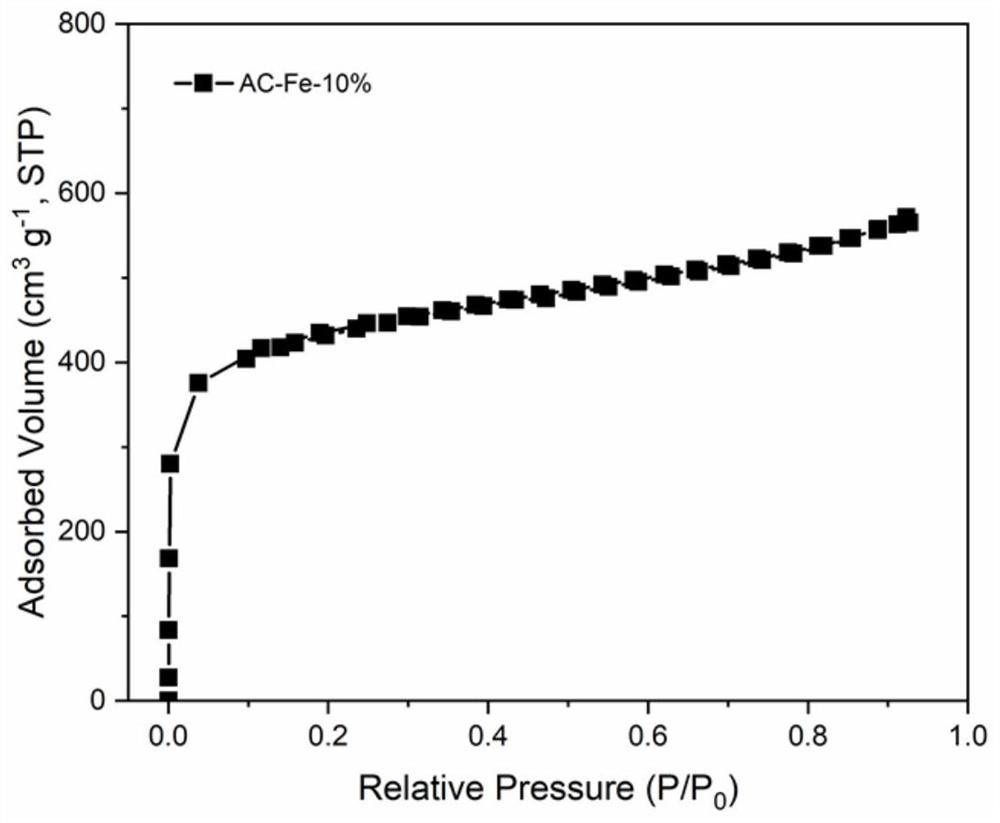

[0037] Raw bamboos were pulverized by a turbine grinder, passed through a 40-mesh standard sieve, and then dried in a blast drying oven at 105°C for 12 hours. Get 6g pulverized moso bamboo raw material and 0.6g Fe 2 (SO 4 ) 3 Add it into 60ml of ultrapure water, mix it evenly by ultrasonication for 15min at room temperature, then seal it in a hydrothermal reaction kettle with a polytetrafluoroethylene liner, and place it in a muffle furnace at 180°C for 24h. Naturally cool to room temperature after the reaction is completed, filter with suction, wash with absolute ethanol and ultrapure water to remove impurities, and dry at 105°C for 12 hours to obtain iron-modified carbon microsphere / carbon nanosheet composite hydrothermal carbon. The iron-modified carbon microsphere / carbon nanosheet composite hydrothermal carbon and potassium bicarbonate were mixed at a mass ratio of 1:6 and then fully ground in a mortar. The obtained mixture was placed in a tube furnace, and the temperat...

Embodiment 2

[0039] Raw bamboos were pulverized by a turbine grinder, passed through a 40-mesh standard sieve, and then dried in a blast drying oven at 105°C for 12 hours. Get 6g pulverized moso bamboo raw material and 1.2g Fe 2 (SO 4 ) 3 Add it into 60ml of ultrapure water, mix it evenly by ultrasonication for 15min at room temperature, then seal it in a hydrothermal reaction kettle with a polytetrafluoroethylene liner, and place it in a muffle furnace at 200°C for 24h. Naturally cool to room temperature after the reaction is completed, filter with suction, wash with absolute ethanol and ultrapure water to remove impurities, and dry at 100°C for 12 hours to obtain iron-modified carbon microsphere / carbon nanosheet composite hydrothermal carbon. The iron-modified carbon microsphere / carbon nanosheet composite hydrothermal carbon and potassium bicarbonate were mixed at a mass ratio of 1:6 and then fully ground in a mortar. The obtained mixture was placed in a tube furnace, and the temperat...

Embodiment 3

[0041] Raw bamboos were pulverized by a turbine grinder, passed through an 80-mesh standard sieve, and then dried in a blast drying oven at 105°C for 12 hours. Get 6g pulverized moso bamboo raw material and 1.2g Fe 2 (SO 4 ) 3 Add it into 60ml of ultrapure water, mix it evenly by ultrasonication for 15min at room temperature, then seal it in a hydrothermal reaction kettle with a polytetrafluoroethylene liner, and place it in a muffle furnace at 180°C for 24h. Naturally cool to room temperature after the reaction is completed, filter with suction, wash with absolute ethanol and ultrapure water to remove impurities, and dry at 105°C for 12 hours to obtain iron-modified carbon microsphere / carbon nanosheet composite hydrothermal carbon. The iron-modified carbon microsphere / carbon nanosheet composite hydrothermal carbon and potassium bicarbonate were mixed at a mass ratio of 1:2 and then fully ground in a mortar. The obtained mixture was placed in a tube furnace, and the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com