Lithium sodium manganate cathode material and preparation method thereof

A technology of sodium manganate and lithium positive electrode, which is applied in the field of new lithium-ion battery positive electrode materials, can solve the problem of low capacitance of electrode materials, and achieve the effects of environmental friendliness, low production cost and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

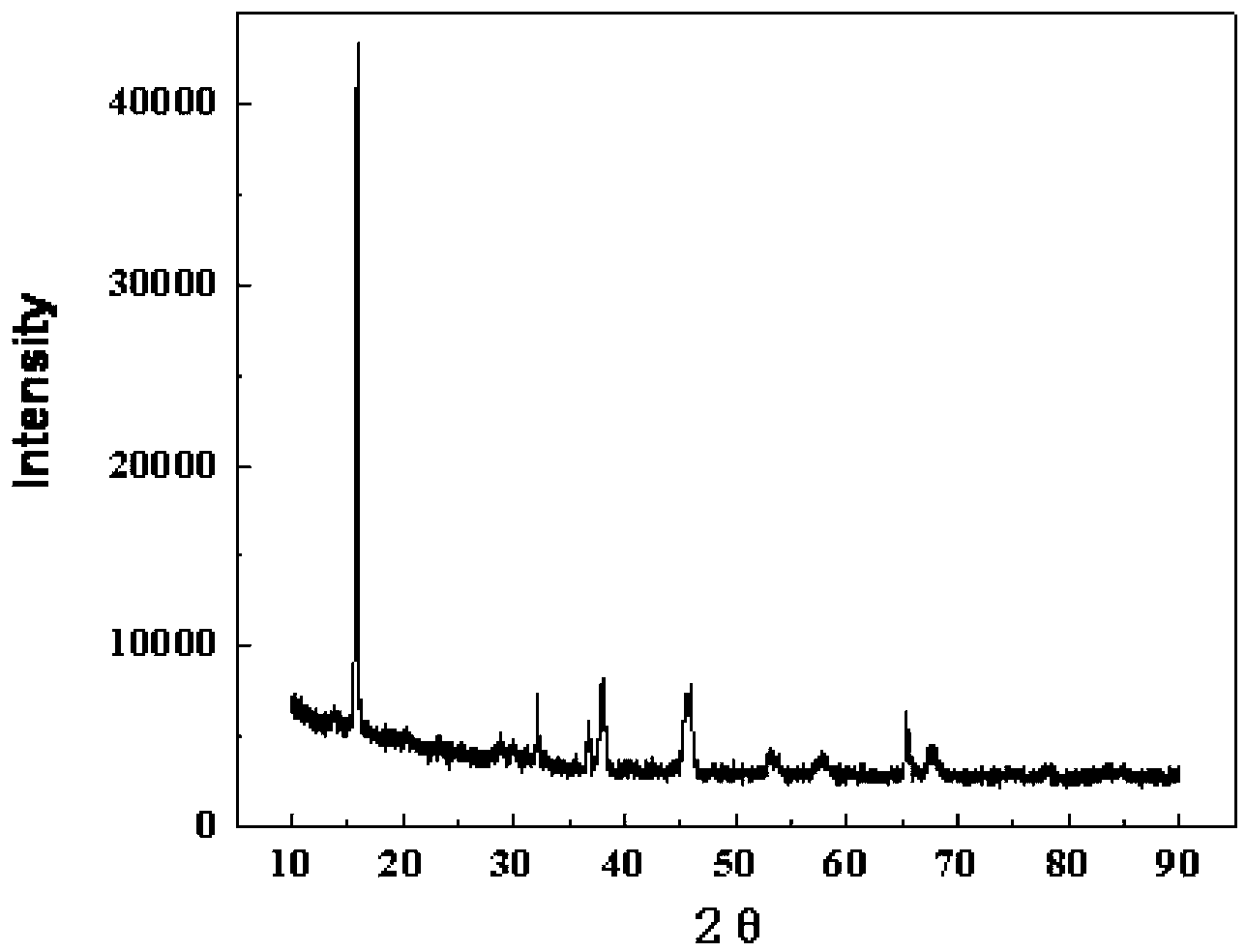

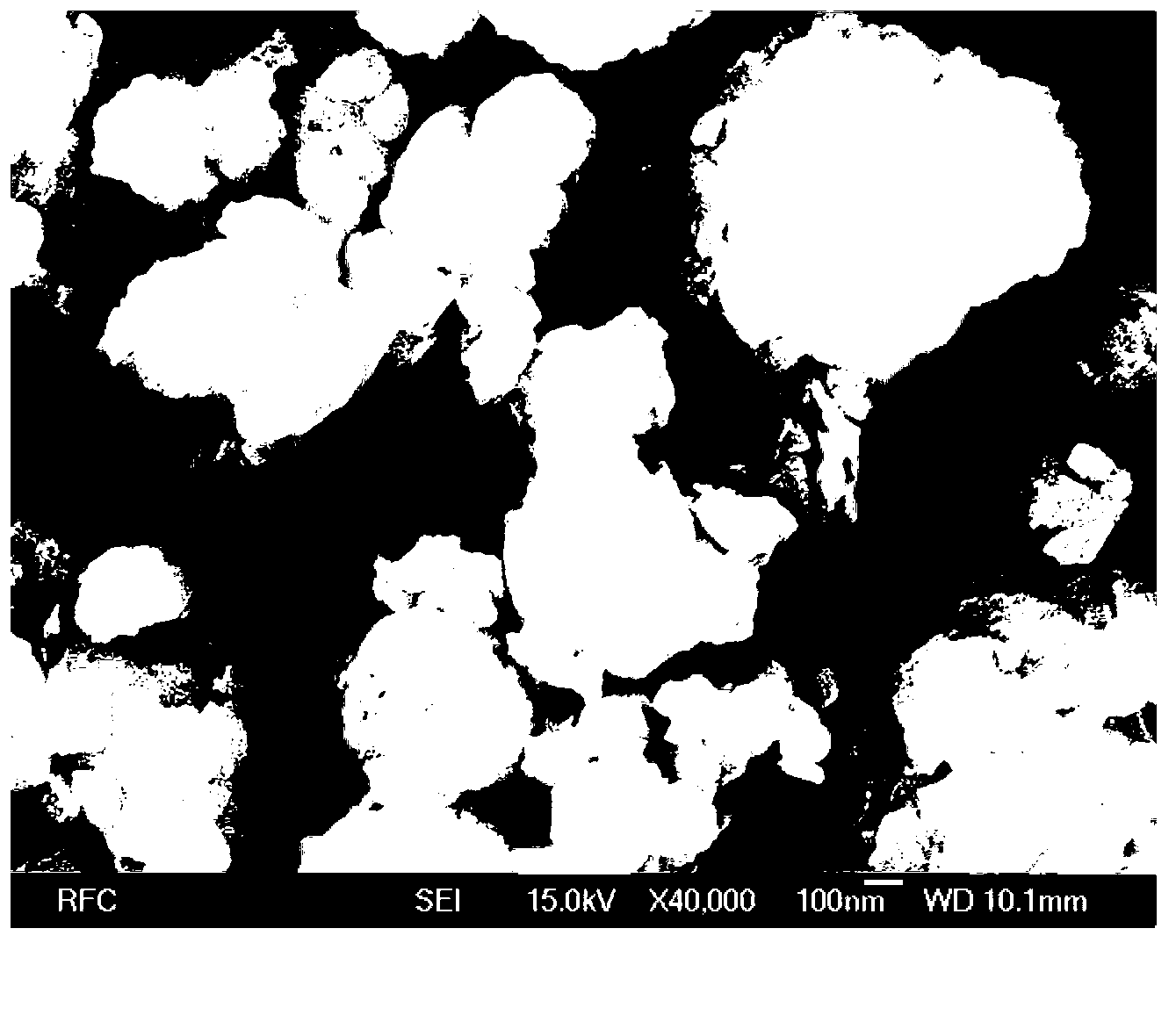

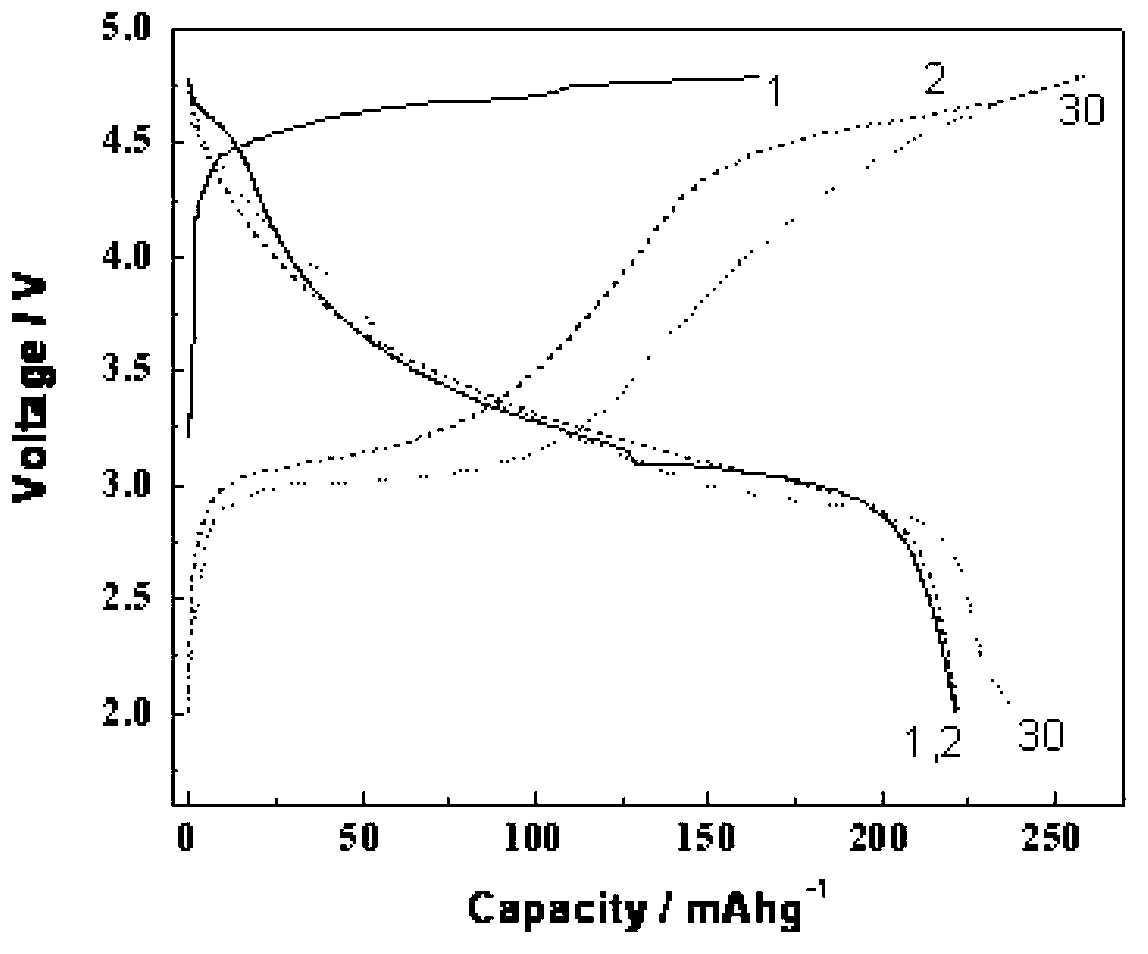

[0039] LiOH·H 2 O, NaOH, electrolytic MnO 2 , mixed at a molar ratio of 1:3:4, dispersed in ethanol, placed in a planetary ball mill at a speed of 500 rpm for 4 hours. Then, in an argon atmosphere, the temperature was raised to 600° C. at a rate of 2° C. / min, roasted at a constant temperature for 8 hours, and then cooled naturally with the furnace. The nominal composition of the resulting product is Li 1 / 4 Na 3 / 4 MnO 2 , XRD analysis ( figure 1 ) shows that it has Na 0.7 MnO 2 Structured single-phase compounds. The primary particle size is 100~300nm, with a certain degree of agglomeration ( figure 2 ). Mix it with acetylene black and polyvinylidene fluoride (PVDF) at a mass ratio of 8:1:1, add an appropriate amount of organic solvent N-methylpyrrolidone (NMP) as a dispersant, grind it evenly and coat it on a 0.02mm current collector After being vacuum-dried at 120° C. on an aluminum foil, it was stamped into a positive electrode disc with a diameter of 14 mm. Use m...

Embodiment 2

[0042] LiOH·H 2 O, NaOH, MnCO 3 , mixed at a molar ratio of 1:2:3, dispersed in ethanol, placed in a planetary ball mill at a speed of 600 rpm for 6 hours. Then in an air atmosphere, the temperature was raised to 700° C. at a rate of 1° C. / min, roasted at a constant temperature for 48 hours, and then cooled naturally with the furnace. The nominal composition of the resulting product is Li 1 / 3 Na 2 / 3 MnO 2 . A battery was assembled according to the method of Example 1, and a charge and discharge test was carried out. The results show that the specific capacity of the first discharge is 196mAh / g, and the specific capacity of the second discharge is 241mAh / g. As the cycle progresses, the specific capacity of the 30th discharge is 252mAh / g.

Embodiment 3

[0044] Will Li 2 CO 3 , Na 2 CO 3 , MnCO 3 , mixed at a molar ratio of 1:1:4, dispersed in ethanol, placed in a planetary ball mill at a speed of 600 rpm for 6 hours. Then in an air atmosphere, the temperature was raised to 700° C. at a rate of 1° C. / min, roasted at a constant temperature for 24 hours, and then cooled naturally with the furnace. The nominal composition of the resulting product is Li 1 / 2 Na 1 / 2 MnO 2 , XRD shows that it is a layered material (Na 0.7 MnO 2 phase) and spinel materials (LiMn 2 o 4 )mixture. A battery was assembled according to the method of Example 1, and a charge and discharge test was carried out. The results show that there are multiple platforms on the charge and discharge curve, and the discharge curve has at least four platforms of 4V, 2.9V, 2.7V and 2V, which proves that the material is a mixture of layered materials and spinel materials, and the specific capacity of the first discharge is 196mAh / g, the specific capacity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com