Patents

Literature

78results about How to "The preparation process is simple and mature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-light-shading acrylonitrile butadiene styrene (ABS) composite material and preparation method thereof

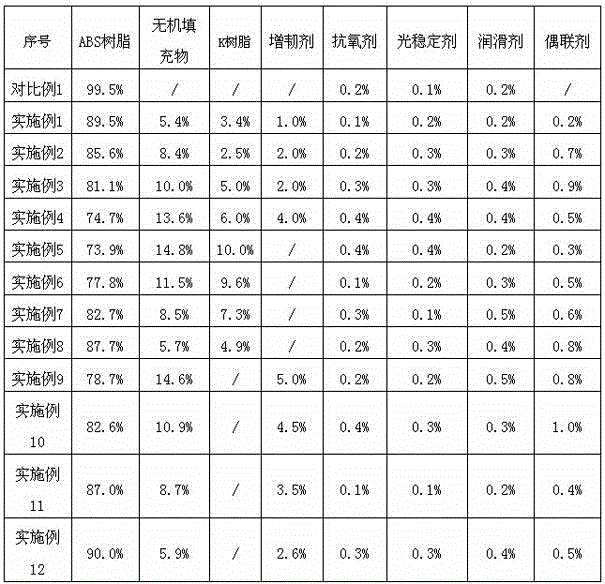

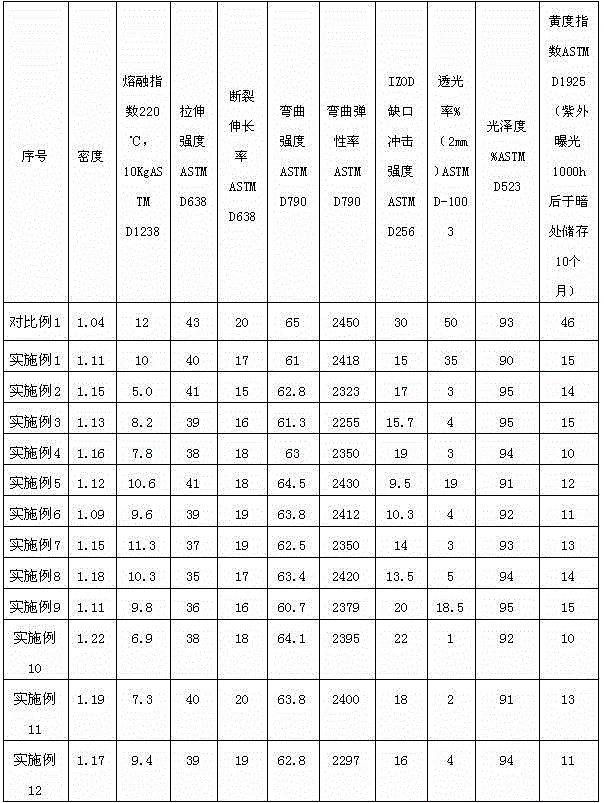

The invention relates to the technical field of modification of acrylonitrile butadiene styrene (ABS) materials and in particular relates to a high-light-shading ABS composite material and a preparation process thereof. The ABS composite material consists of the following raw materials in percentage by weight: 70 to 90 percent of ABS resin, 5 to 15 percent of an inorganic filler, 0 to 15 (0 to 10) percent of a styrene-butadiene copolymer, 0 to 10 (0 to 5) percent of a flexibilizer, 0.1 to 0.5 percent of an antioxidant, 0.1 to 0.5 percent of a light stabilizer, 0.1 to 0.5 percent of a lubricating agent and 0.2 to 1.0 percent of a coupling agent. The high-light-shading ABS composite material has white appearance and high light-shading performance, meets the requirements of shells of IT equipment and lampshades of lighting lamps on high light-shading performance and light aging resistance, and has high surface gloss.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

Soil heavy metal biological fixing agent and application method thereof

ActiveCN103275728ALow costReduce environmental risksAgriculture tools and machinesContaminated soil reclamationSoil heavy metalsNutrient

The invention relates to the technical field of soil conditioners and particularly relates to a soil heavy metal biological fixing agent and an application method thereof. The formula of the soil heavy metal biological fixing agent is that every one kilogram of an organic fertilizer is added with 2-10 g (109 CFU / g) of B. natto solid leavening agent, 2-10 g (109 CFU / g) of B.mucilaginosus solid leavening agent, 2-6 g (109 CFU / g) of B.megaterium solid leavening agent and 4-10 g (1010 CFU / g) of Trichoderma koningii solid leavening agent, wherein the main ingredients of the biological organic fertilizer contain more than 40% of organic matter, more than 20 million / g of effective viable count, and more than 5% of total nutrient. The soil heavy metal biological fixing agent is low in cost, has few environmental risks, remarkably reduces the absorption of the heavy metals of the crops, improves the soil fertility, effectively prevents and cures the soil-borne diseases and increases the economic benefit of the crops.

Owner:DONGGUAN BAODE BIOLOGICAL ENG

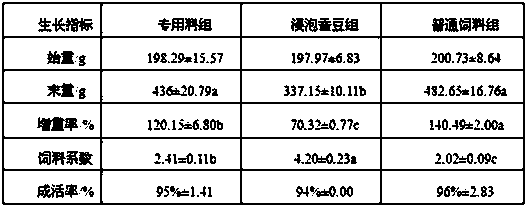

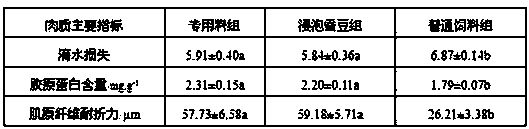

Special formula feed for improving tilapia mossambica meat quality and preparation method thereof

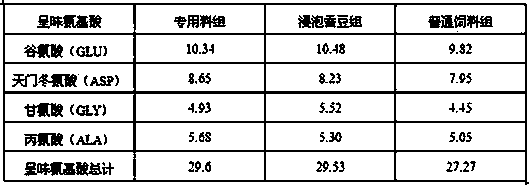

InactiveCN103380861AImprove meat qualityFirm and crispy meatClimate change adaptationAnimal feeding stuffBiotechnologyAnimal science

The invention relates to the field of aquatic feed, in particular to special formula feed for improving tilapia mossambica meat quality and a preparation method thereof. Ingredients in a feed formula comprise, by weight, 40-70 parts of broad bean, 2-5 parts of fish meal, 7-12 parts of bran, 9-19 parts of rapeseed dregs, 8-19 parts of peanut meal, 1-2 parts of fish oil, 0.3-0.5 part of glycine betaine, 0.4-0.6 part of choline chloride, 0.6-0.8 part of monocalcium phosphate, 0.10-0.13 part of methionine, 0.06-0.1 part of enzyme preparation, 0.02-0.03 part of allicin, 0.4-0.6 part of multivitamins and 1.0-1.2 parts of complex mineral. The preparation method of the feed is further provided. The feed can improve the tilapia mossambica meat quality to be firm, hard, crisp and tasty, improves growth performance of tilapia mossambica, reduces pollution on water quality and production cost and remarkably improves economical and social benefit.

Owner:福建省淡水水产研究所

Special compound feed for tilapia meat quality improvement and preparation method thereof

InactiveCN103960529AImprove meat qualityFirm and crispy meatClimate change adaptationAnimal feeding stuffBiotechnologyAnimal science

The invention relates to the field of aquatic feed and particularly provides special compound feed for tilapia meat quality improvement and a preparation method thereof. The feed comprises the following components in parts by weight: 40-70 parts of broad bean, 2-5 parts of fish meal, 7-12 parts of bran, 9-19 parts of rapeseed mea1, 8-19 parts of peanut meal, 1-2 parts of fish oil, 0.3-0.5 part of glycine betaine, 0.4-0.6 part of choline chloride, 0.6-0.8 part of monocalcium phosphate, 0.10-0.13 part of methionine, 0.06-0.1 part of enzyme preparation, 0.02-0.03 percent of garlicin, 0.4-0.6 percent of compound vitamin and 1.0-1.2 parts of composite mineral salt. The invention also provides a preparation method of the feed. The feed has the benefits that the tilapia meat quality can be improved, so that tilapia meat is hard and crisp; and the growth performance of tilapia is improved, so that the pollution to the water quality is reduced, and the production cost is reduced, therefore, the economic and social benefits are remarkable.

Owner:福建省淡水水产研究所

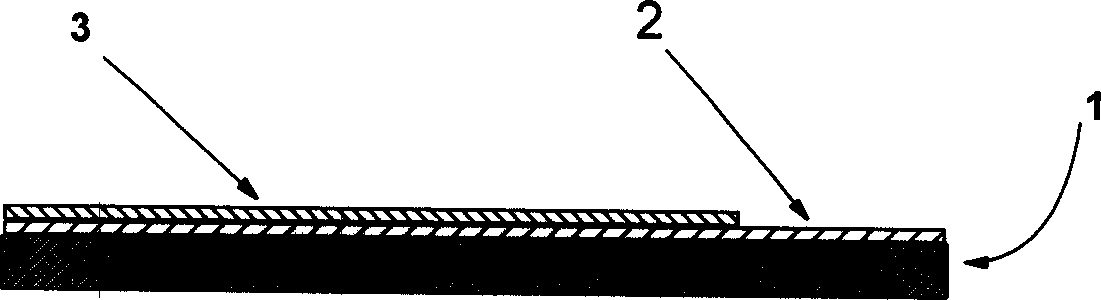

Nano-silver flexible conductive membrane and preparation method thereof

ActiveCN103992495AStable electrical conductivity on the surface of the filmLow resistivityConductive layers on insulating-supportsPretreated surfacesCellulosePolyethylene glycol

The invention relates to the technical field of conductive membranes, particularly to a nano-silver flexible conductive membrane and a preparation method thereof. The nano-silver flexible conductive membrane comprises a PET substrate layer, wherein corona treatment is performed on the surface of the PET substrate layer; a conductive coating layer which is arranged on the surface of the PET substrate layer comprises the following raw materials in percentage by weight: 50-75% of absolute ethyl alcohol, 2-5% of terpilenol, 1-3% of acetyl tributyl citrate, 2-8% of joint cement, 1-5% of polyethylene glycol 400, 2-3% of span 85, 1.5-3% of ethyl cellulose, 3-8% of silver powder of 20-40 nanometers, and 10-18% of silver powder of 150-450 nanometers. The nano-silver flexible conductive membrane, provided by the invention, has the characteristics of stable surface conductivity of the formed film, low resistivity, high light transmittance and strong adhesive force. The preparation process of the nano-silver flexible conductive membrane is simple and mature, coating equipment is simple, the operation is convenient, the cost is low, and the nano-silver flexible conductive membrane facilitates popularization and application.

Owner:杨佳雯

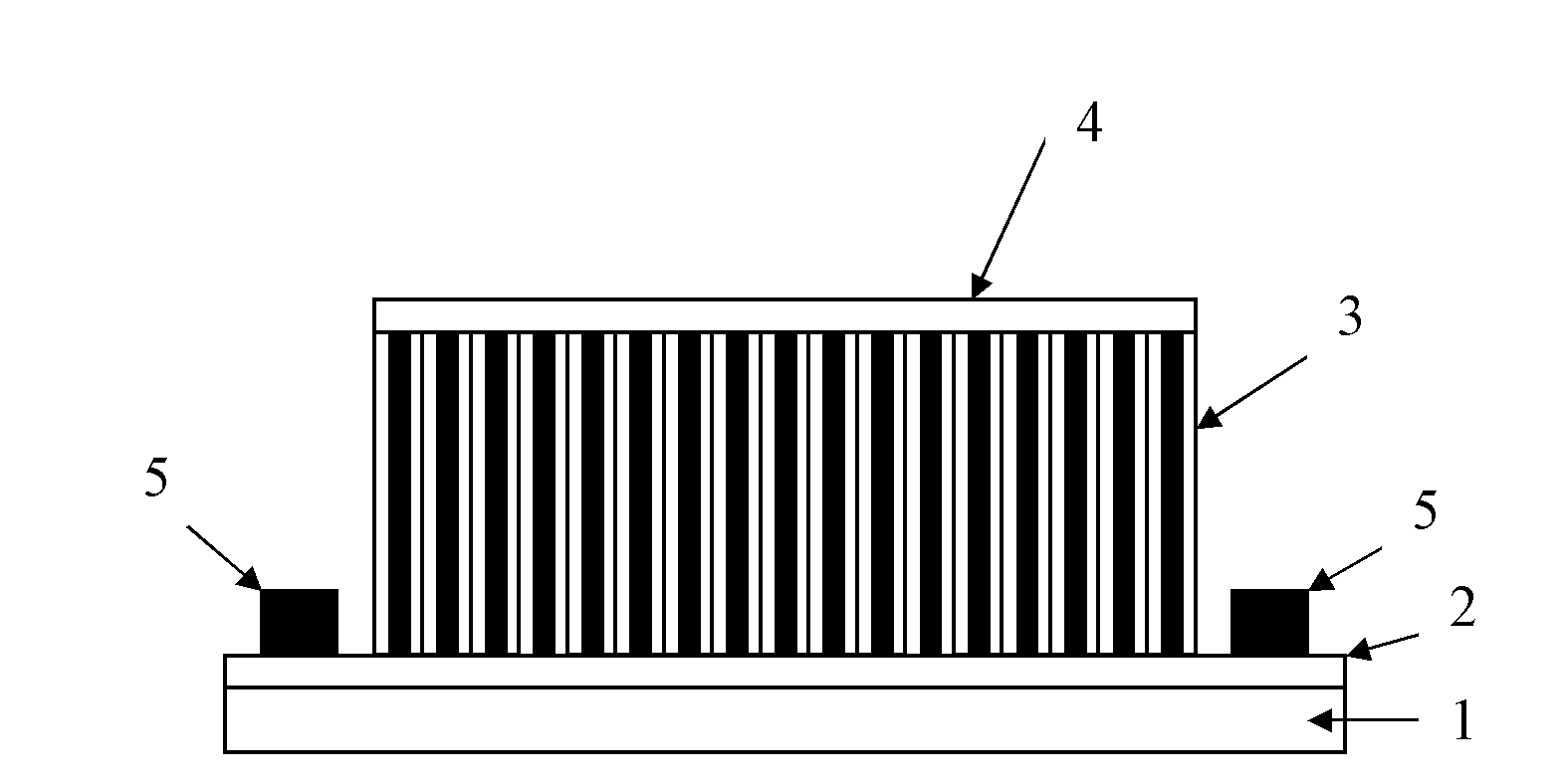

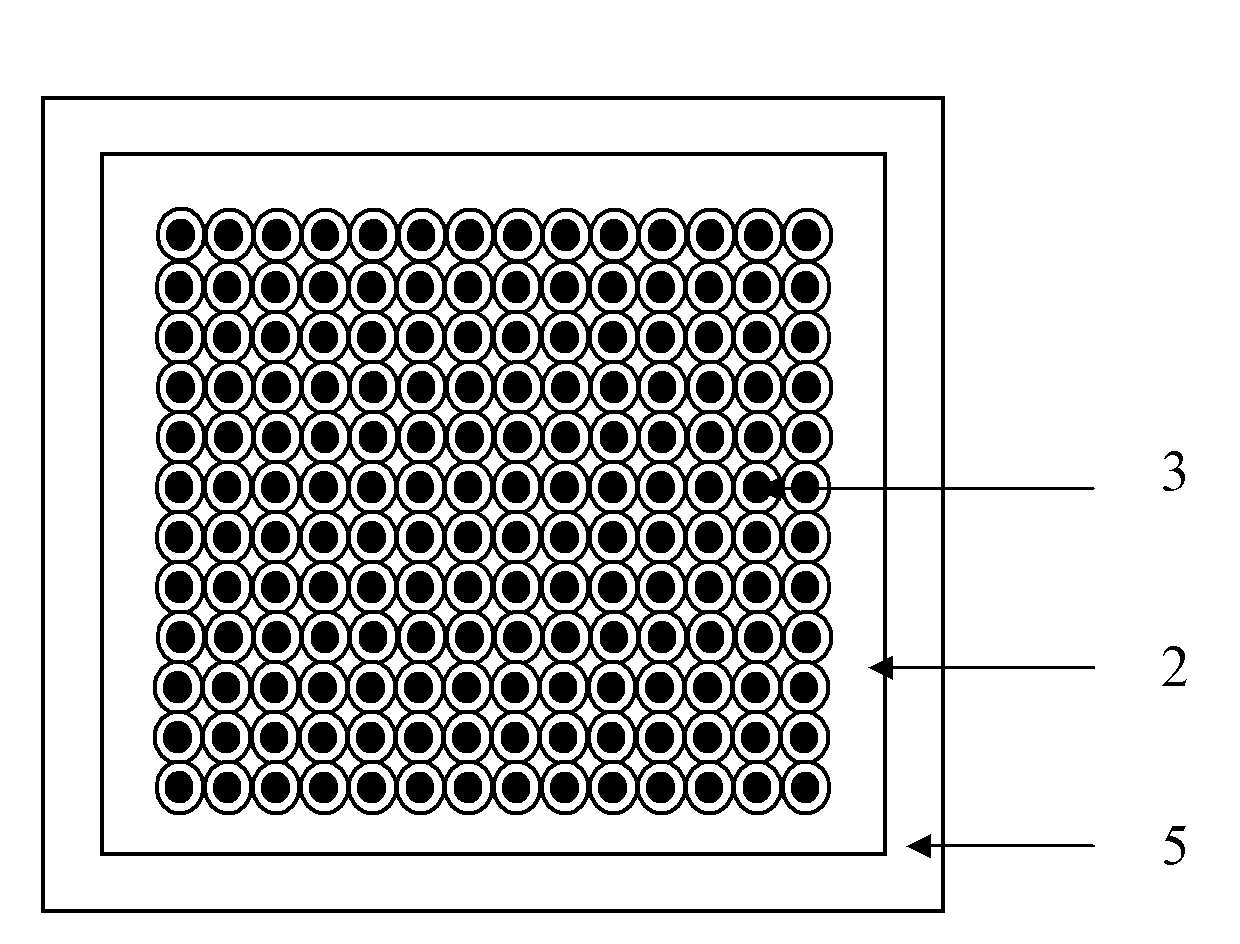

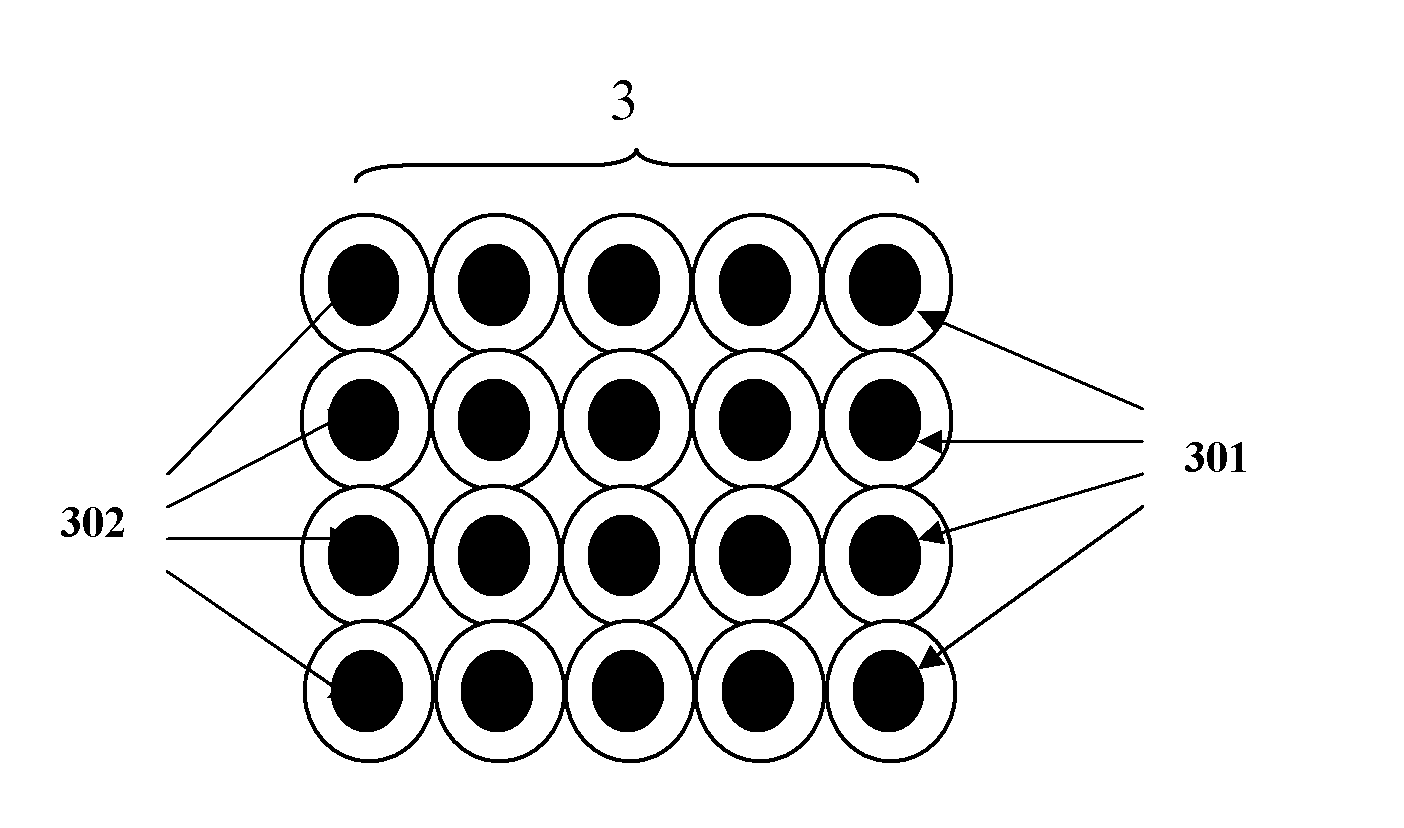

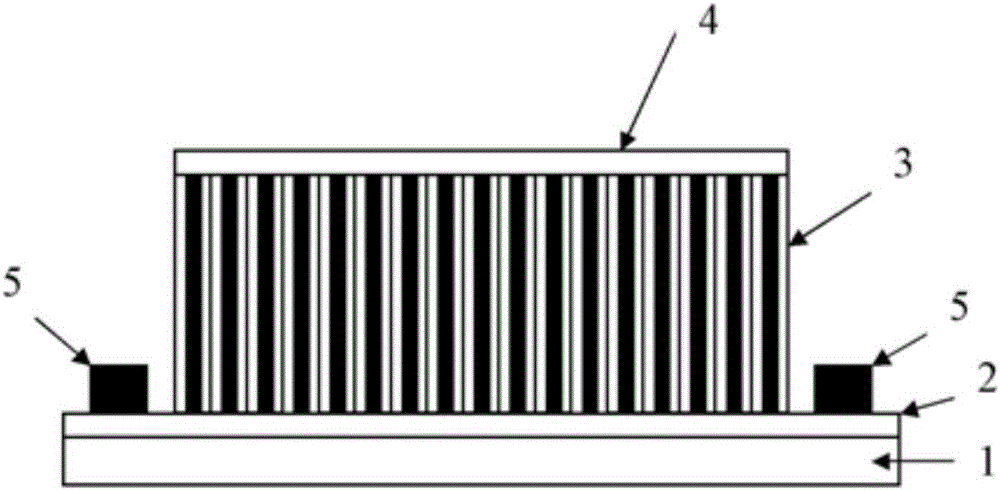

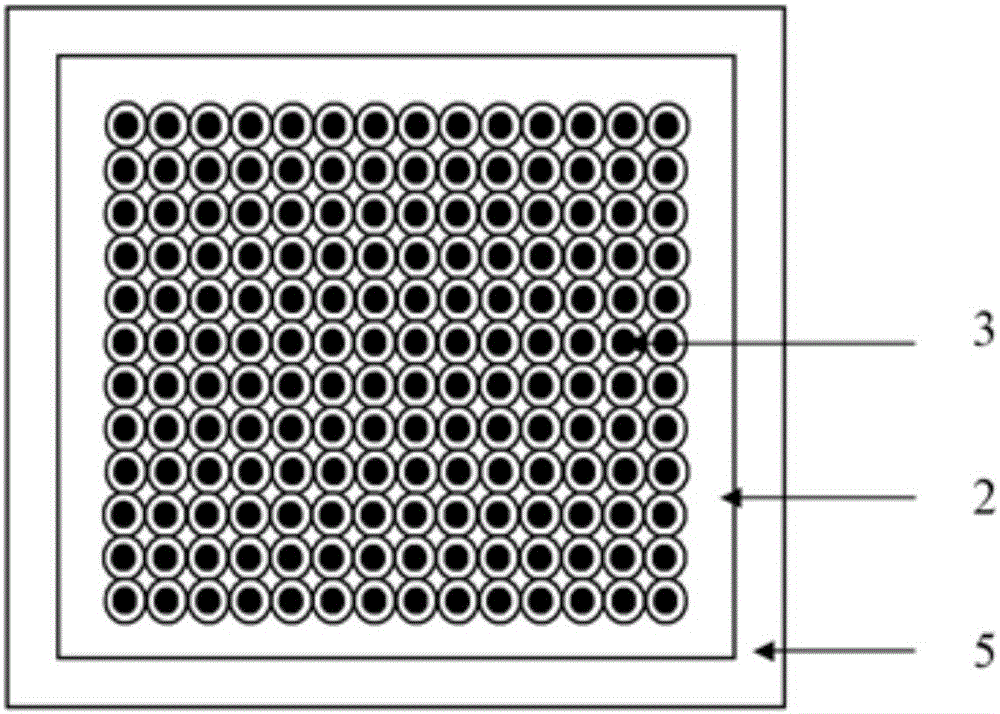

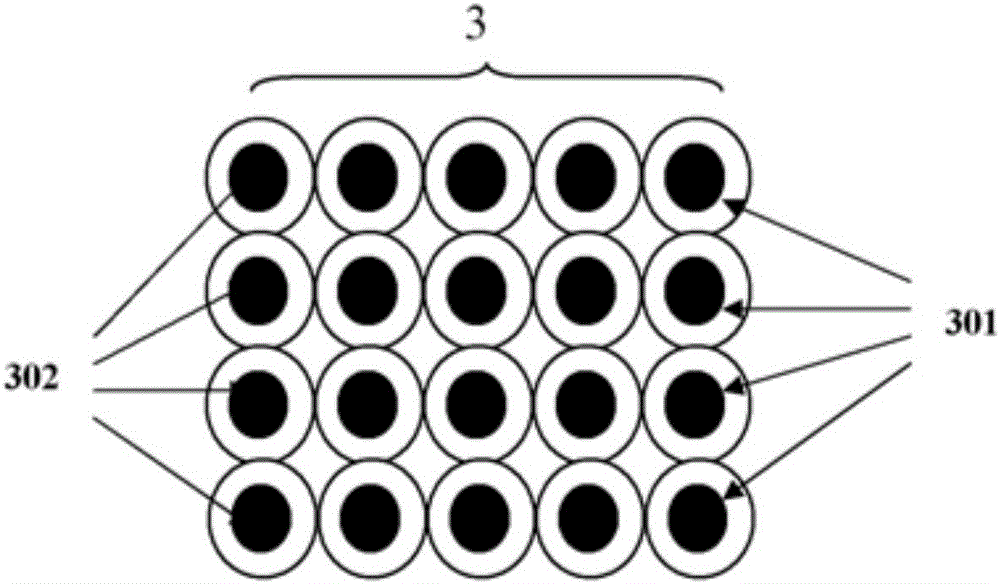

Nano coaxial-cable heterojunction array base ultraviolet detector and manufacturing method thereof

InactiveCN102208479AFast shippingEasy to separateFinal product manufactureDecorative surface effectsCoaxial cableQuantum

The invention discloses a nano coaxial-cable heterojunction array base ultraviolet detector and a manufacturing method thereof. The detector comprises a substrate and a conductive film, a NiO@TiO2 nano coaxial-cable heterojunction array which is used as an ultraviolet absorbing layer and at least one N-type ohmic electrode are arranged on the conductive film, at least one P-type ohmic electrode is arranged on the NiO@TiO2 nano coaxial-cable heterojunction array; and the NiO@TiO2 nano coaxial-cable heterojunction array is composed of a TiO2 nano-tube array and a NiO nano-wire filled in the TiO2 nano-tube. The core structure of the detector provided by the invention is the nano coaxial-cable heterojunction array consisting of the TiO2 nano-tube array and the NiO nano-wire penetrating through the TiO2 nano-tube; the usage rate of a photo-generated carrier can be sufficiently improved, and the nano coaxial-cable heterojunction array base ultraviolet detector has the advantages of high external quantum efficiency and flexibility, small volume and the like.

Owner:DALIAN MARITIME UNIVERSITY

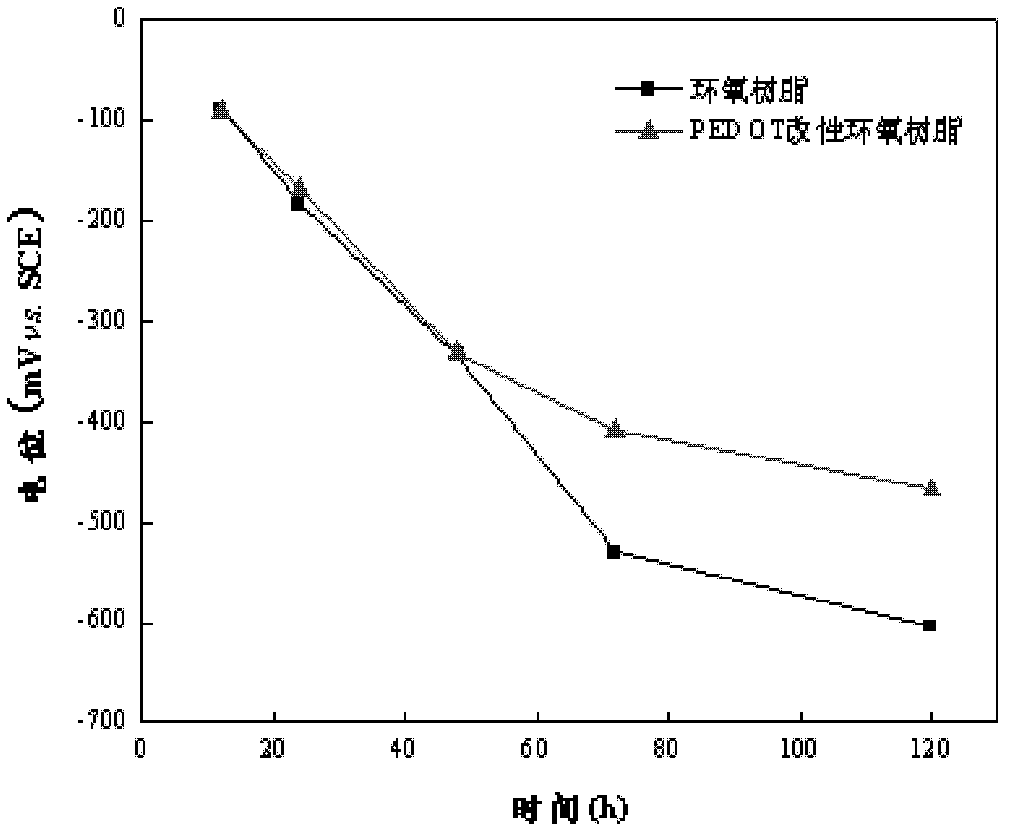

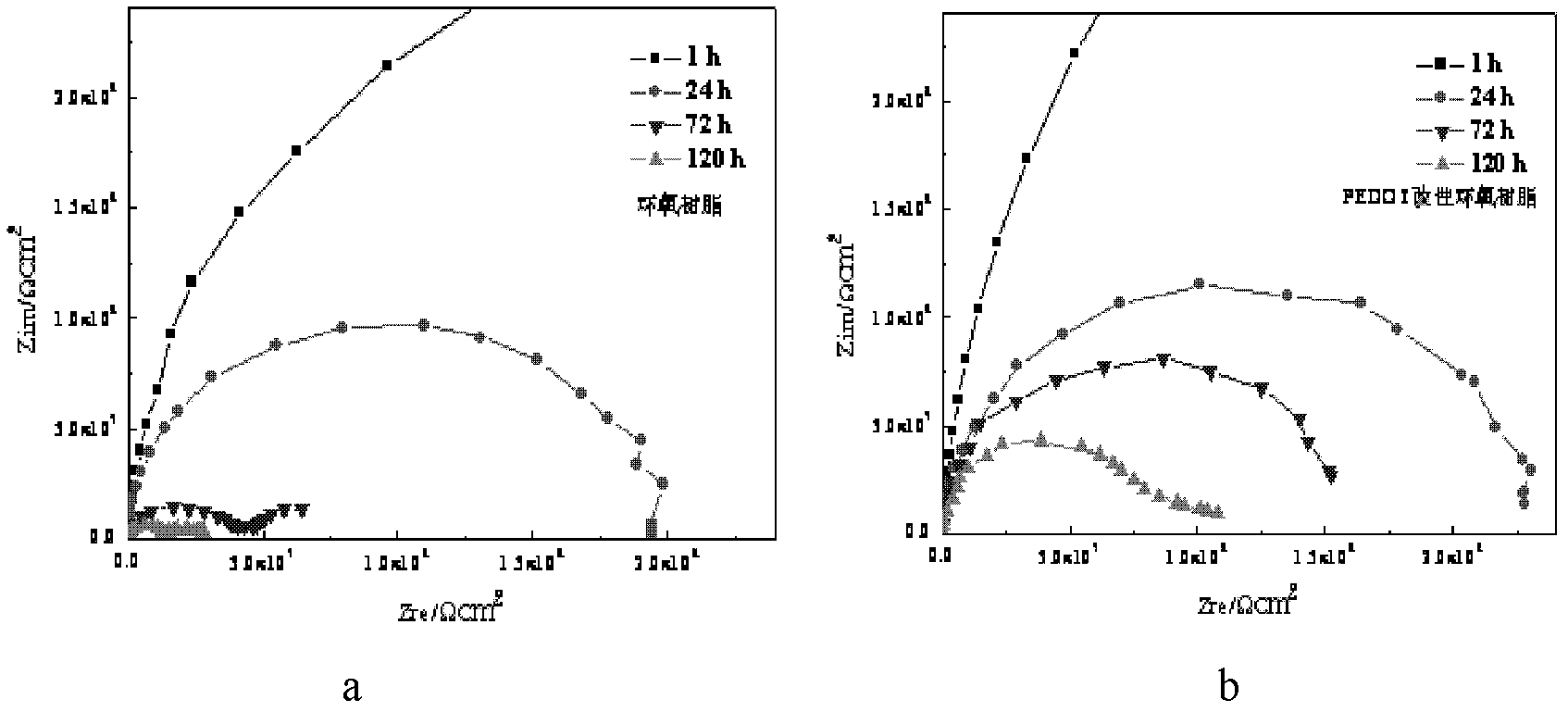

Preparation method for epoxy anticorrosive coating

InactiveCN102559011AImprove solubilityThe preparation process is simple and maturePretreated surfacesAnti-corrosive paintsEmulsionChemistry

The invention relates to a preparation method for an epoxy anticorrosive coating, which belongs to the technical field of preparation of anticorrosive coating materials. The method comprises the following steps: dissolving an emulsifier in water, adding ethylenedioxythiophene monomers into an obtained aqueous solution, cooling the aqueous solution in ice-water bath and carrying out stirring so as to obtain emulsion A; dissolving an oxidizing agent in water, cooling an obtained aqueous solution in ice-water bath and carrying out stirring so as to obtain solution B; slowly mixing the solution B and the emulsion A according to a volume ratio of 1:1, carrying out stirring and allowing the solution B to react with the emulsion A in ice-water bath so as to obtain suspending liquid C; adding acetone into the suspending liquid C for demulsification, carrying out filtering, carrying out repeated rinsing with acetone or water so as to obtain polyethylenedioxythiophene and drying polyethylenedioxythiophene at a temperature of 60 DEG C in vacuum so as to obtain solid powder D; and stirring epoxy resin, a curing agent, a diluent and the solid powder D in a container, carrying out ultrasonic treatment for 20 min to 1 h, coating an obtained mixture on a steel plate and curing the steel plate at room temperature so as to obtain the epoxy anticorrosive coating. According to the invention, process route is reasonable, technology is mature, and the prepared anticorrosive coating has the advantages of low cost, excellent performance and good economic effects.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

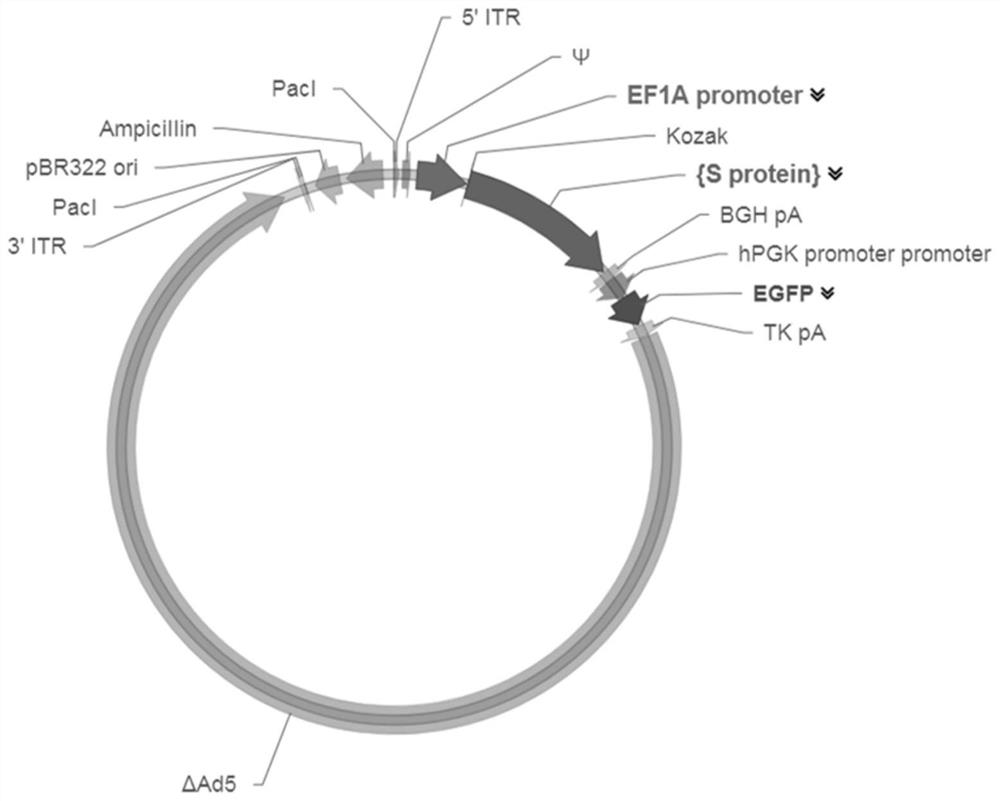

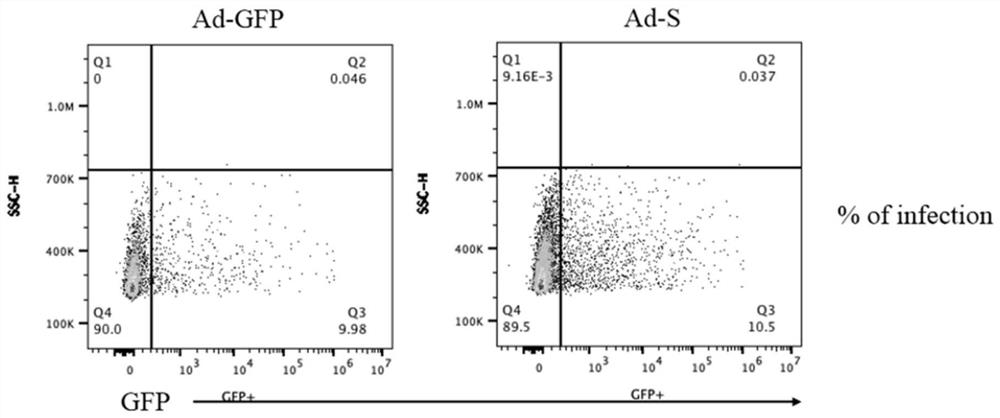

COVID-19 vaccine and preparation method and application thereof

PendingCN112386684AImprove securityWide variety of sourcesSsRNA viruses positive-senseVirus peptidesImmunocompetenceT cell

The invention provides a COVID-19 vaccine and a preparation method and application thereof. The COVID-19 vaccine comprises T cells expressing SARS-CoV-2 S protein. The preparation method of the COVID-19 vaccine comprises the following steps that (1), coding genes of the SARS-CoV-2 S protein are inserted into an adenovirus vector to construct a recombinant adenovirus vector; (2), the recombinant adenovirus vector and packaging helper plasmids are used for co-transfecting mammalian cells to prepare recombinant adenovirus; and (3), the recombinant adenovirus is adopted for infecting the T cells to obtain the COVID-19 vaccine. According to the COVID-19 vaccine and the preparation method and application thereof, a virus system is utilized for constructing the recombinant T cells expressing theSARS-CoV-2 S protein, the recombinant T cells are input into a body to continuously express the S protein, the body is induced to generate a specific humoral immune response or a cellular immune response, and the body obtains the protective immunity capacity on SARS-CoV-2.

Owner:广东昭泰细胞生物科技有限公司

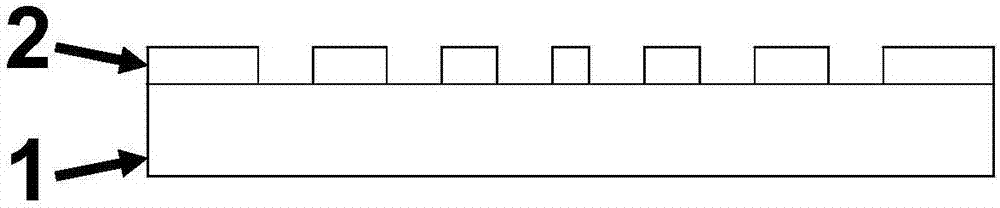

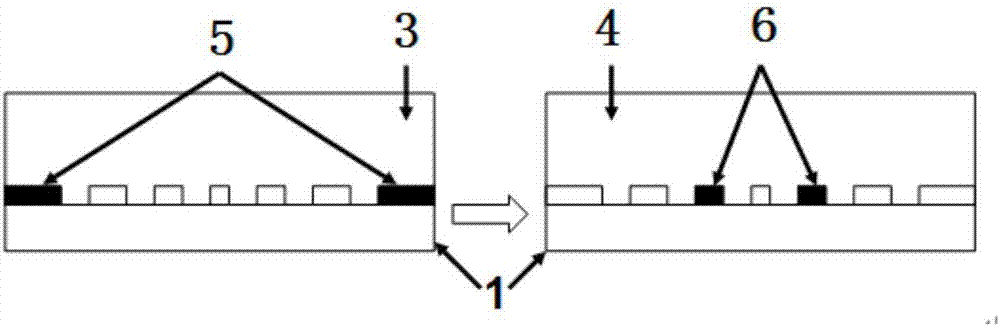

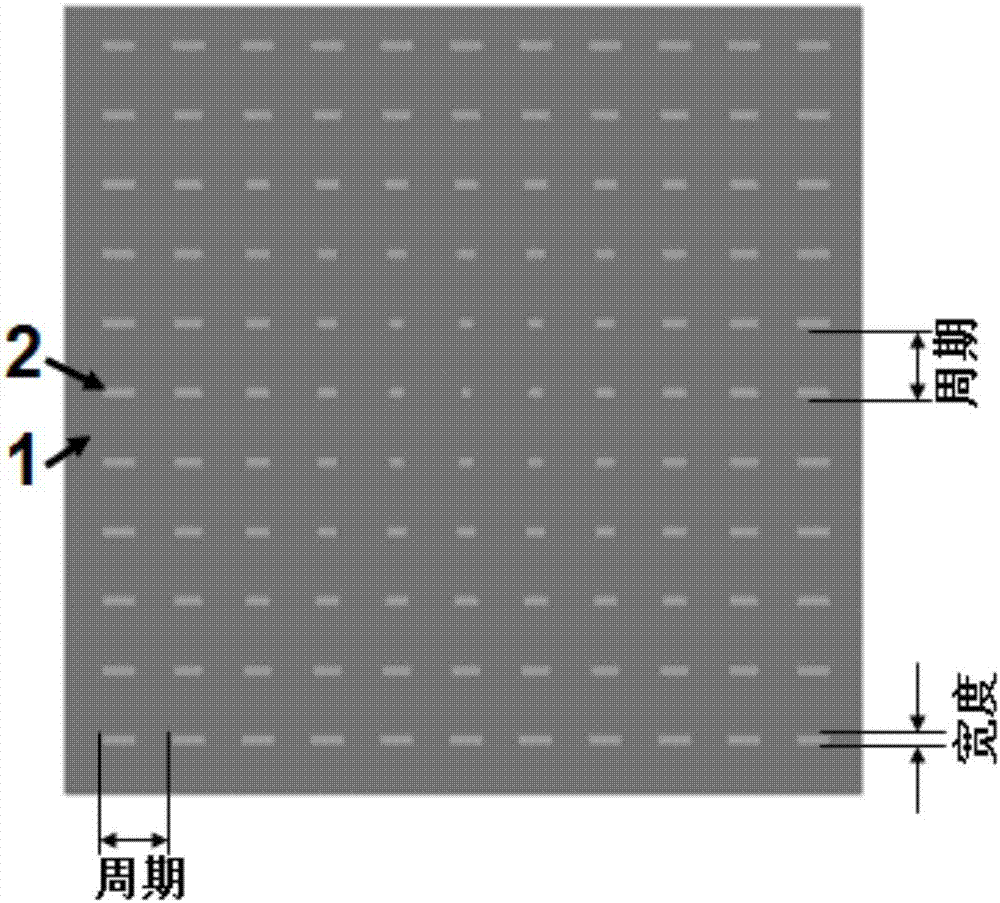

Plasmon refractive index sensor based on nano pattern and sensing method thereof

ActiveCN106940296AImplement detectionWide light sourcePhase-affecting property measurementsRefractive indexColor changes

The invention discloses a plasmon refractive index sensor based on a nano pattern and a sensing method thereof. The sensor comprises a layer of plasmon nano antenna array and a flat transparent substrate supporting the antenna array, the plasmon nano antenna array is a periodic array structure, the period is 50 to 1000 nanometers, and the thickness is 10 to 100 nanometers; the size of a single nano antenna of the array structure gradually changes according to a certain law, and the changing range is from 10 to 10000 nm. The sensor uses an imaging device to detect brightness and color change of a finite difference time domain method nano antenna array on the sensor in to-be-tested medium environment or position change of a resonance nano antenna under monochromatic light or white light irradiation to achieve medium refractive index sensing. The plasmon refractive index sensor has the advantages of simple detection technique, high sensitivity, good stability, low cost of needed detection equipment, and the like.

Owner:NANJING UNIV

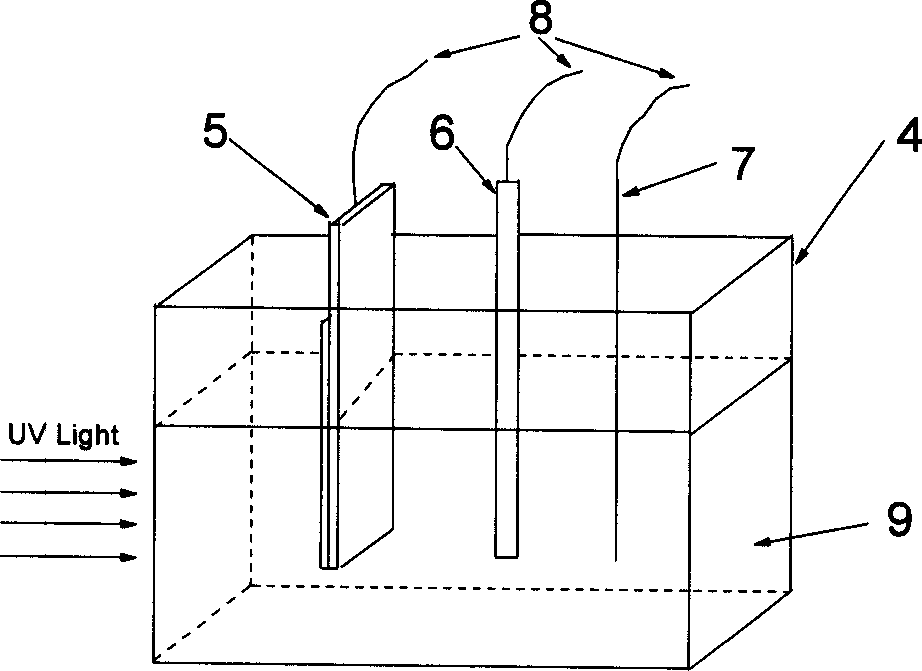

Ultraviolet sensor with nanometer TiO-M thin film and production thereof

InactiveCN1819278AThe preparation process is simple and matureLow priceFinal product manufacturePhotometrySignal processing circuitsUltraviolet lights

The invention consists of an ultraviolet photo-detector using TiO2 film as a layer of absorbing ultraviolet, a relevant offset voltage circuit, a current switching circuit and a signal processing circuit. The ultraviolet photo-detector is a wideband nano TiO2 film sensor that only has high sensitive response for ultraviolet light shorter than 380nm, and doesn't sense infrared light and visible light. Thereby it can prevent interference of other light sources except ultraviolet.

Owner:DALIAN MARITIME UNIVERSITY

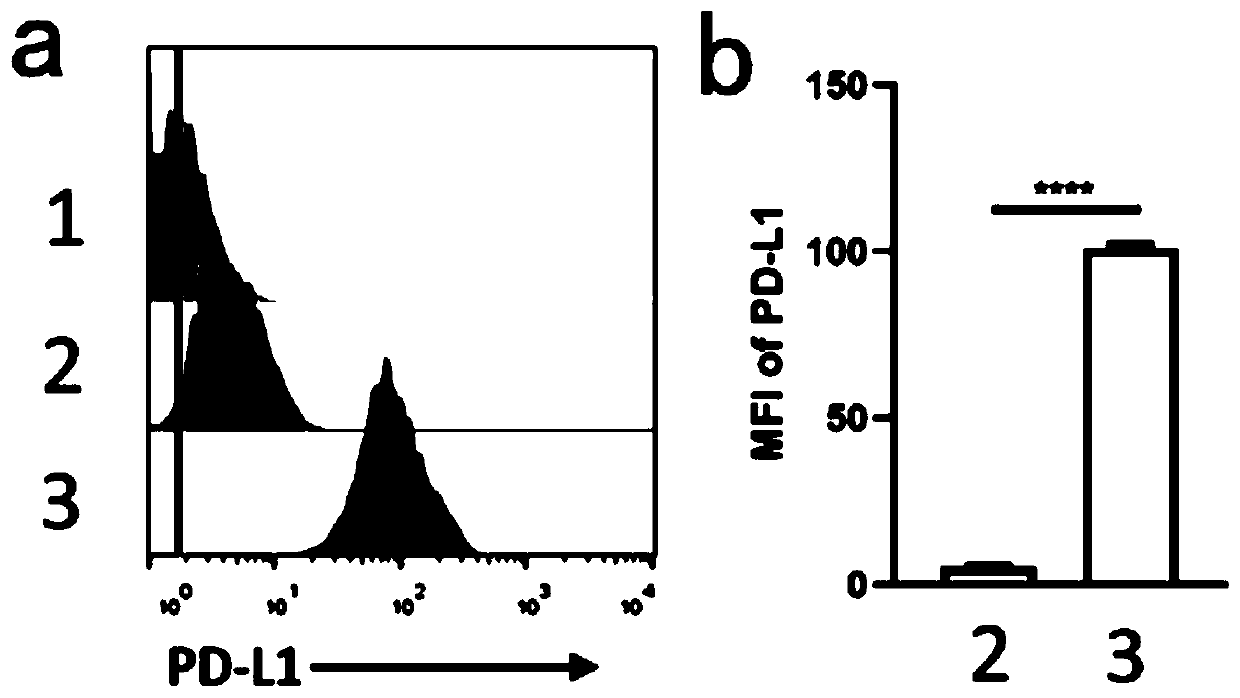

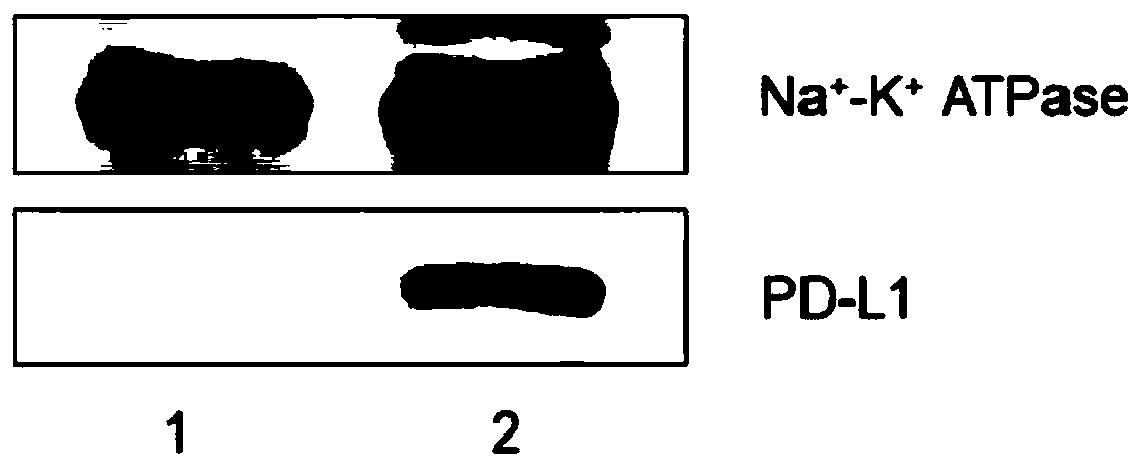

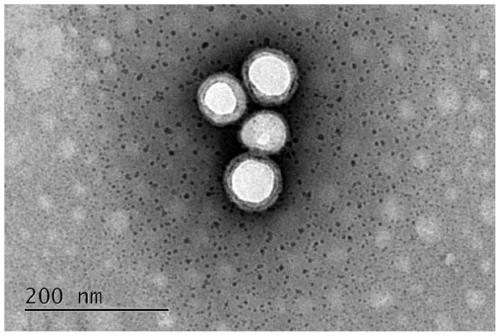

Mesenchymal stem cell membrane-coated bionic nanoparticles with overexpressed PD-L1 molecules on surface as well as preparation and application of mesenchymal stem cell membrane-coated bionic nanoparticles

ActiveCN111265549AThe preparation process is simple and matureHigh biosecurityAntibacterial agentsAntimycoticsCell membraneImmunity response

The invention relates to mesenchymal stem cell membrane-coated bionic nanoparticles with overexpressed PD-L1 molecules on the surface as well as preparation and application of the mesenchymal stem cell membrane-coated bionic nanoparticles. The mesenchymal stem cell membrane-coated bionic nanoparticle with the overexpressed PD-L1 molecules on the surface comprises a nano-core and a mesenchymal stemcell membrane wrapping the nano-core, the nano core comprises a polymer with biocompatibility, and PD-L1 molecules are overexpressed on the membrane surface of the mesenchymal stem cell membrane. Theinvention also discloses an application of the mesenchymal stem cell membrane-coated bionic nano-particle with over-expressed PD-L1 molecules on the surface in preparation of an inflammation treatment preparation. The bionic nanoparticle has a remarkable immunosuppression effect, is high in biocompatibility and simple and mature in preparation process, can be used for preparing an inflammation treatment preparation, can be effectively enriched in an inflammation part, and shows an excellent curative effect in inflammation treatment by inhibiting excessively activated immune response and cytokine storm of the inflammation part.

Owner:SUZHOU UNIV

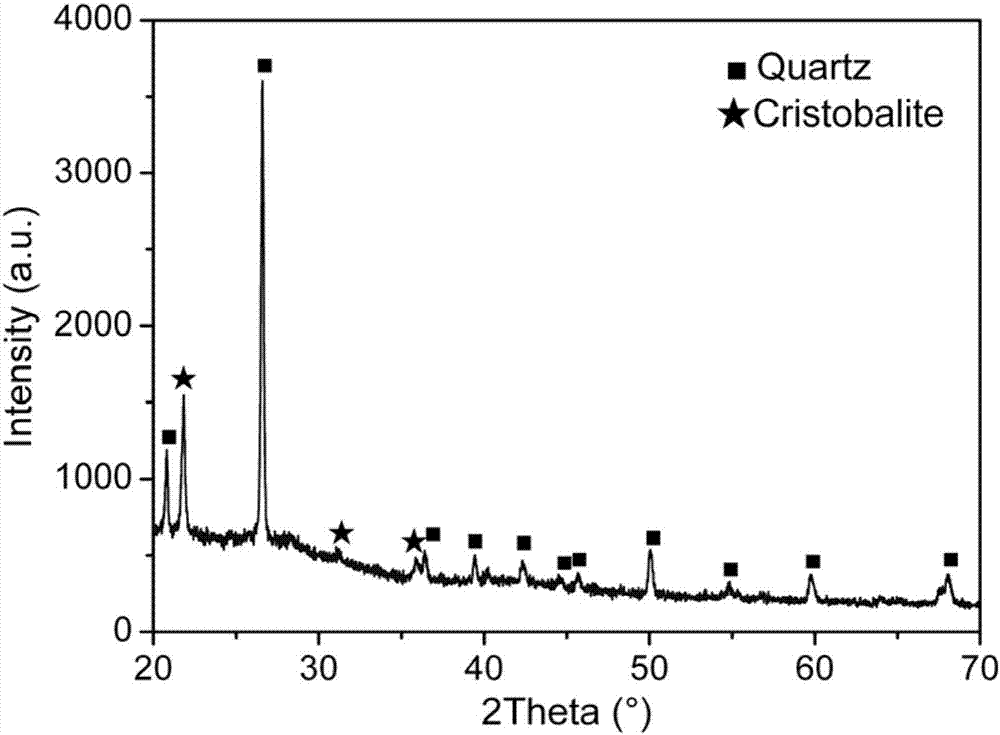

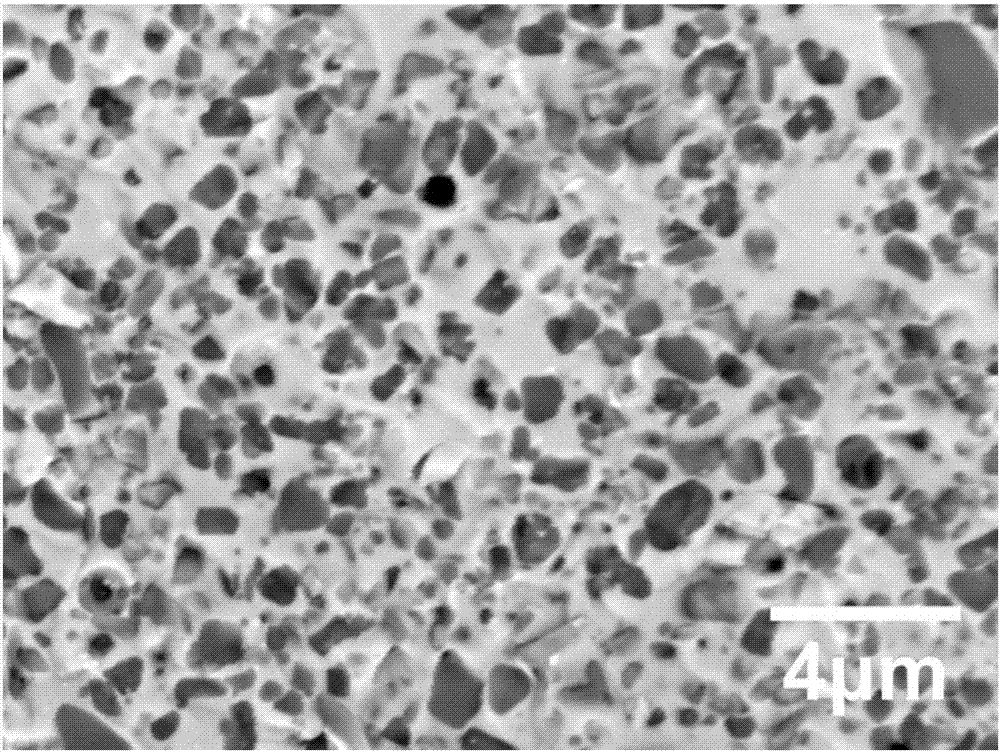

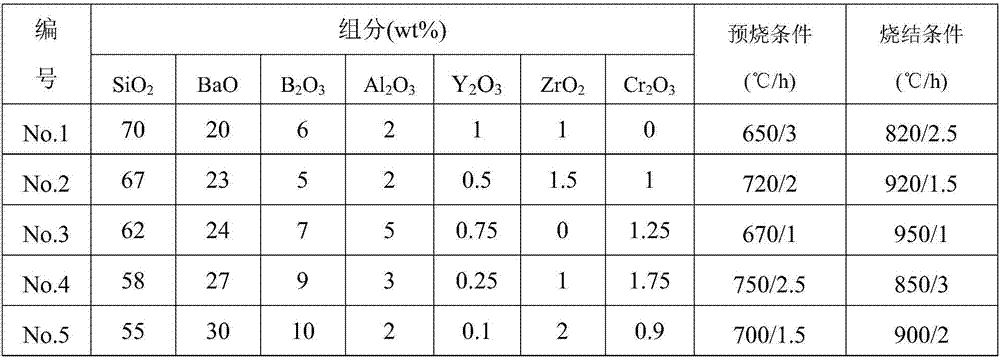

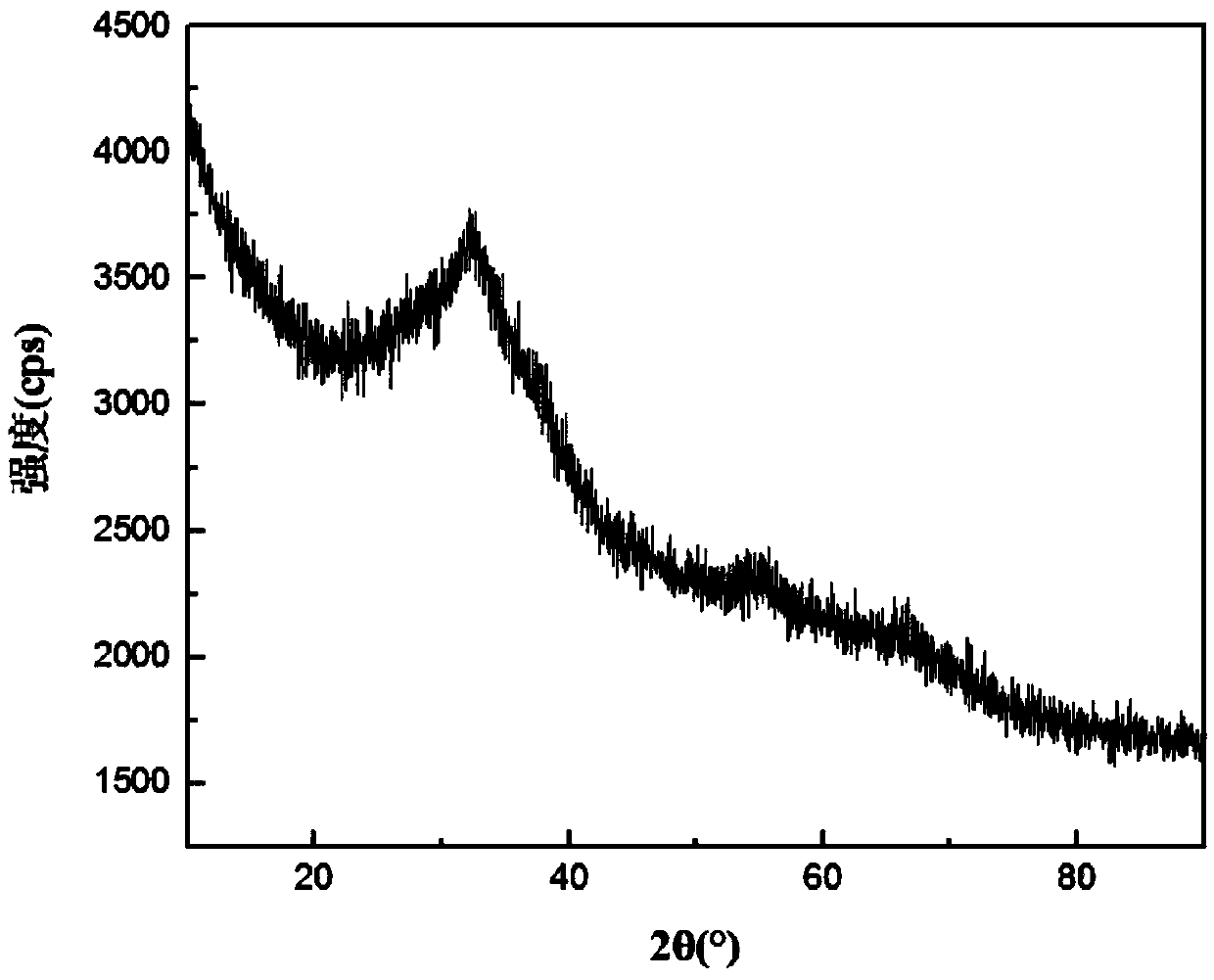

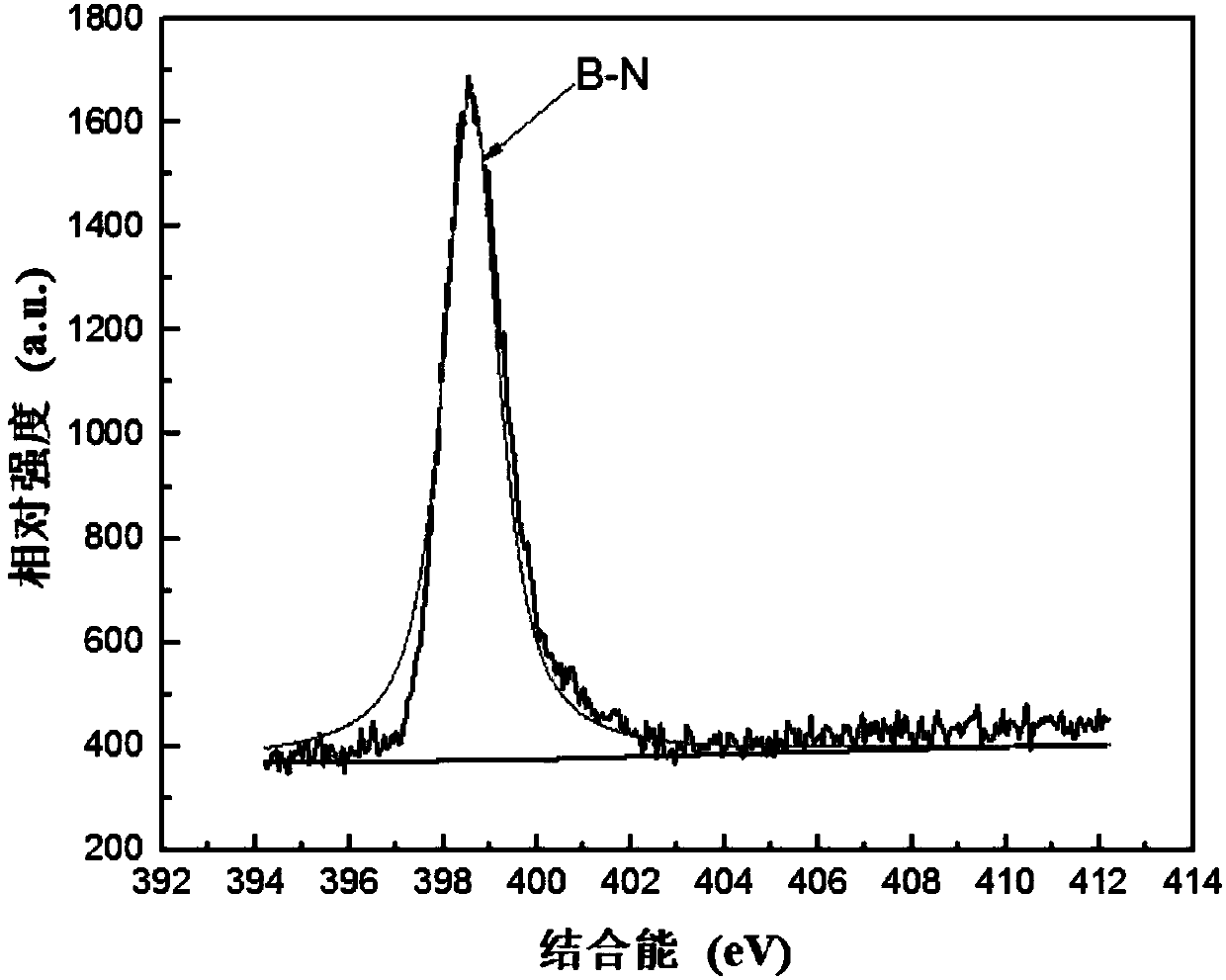

High-thermal-expansion-coefficient ceramic material for high density packaging and preparation method thereof

The invention belongs to the technical field of electronic ceramic packaging material and provides a high-thermal-expansion-coefficient ceramic material for high density packaging and a preparation method thereof so as to overcome the problem of thermal expansion mismatch of existing chip packaging materials. The ceramic material of the invention comprises the following ingredients (by weight): 55-70% of SiO2, 20-30% of BaO, 5-10% of B2O3, 2-5% of Al2O3, 0.1-1% of Y2O3, and 1-3% of a mixture of CrO2 and ZrO2. Thermal expansion coefficient of the ceramic material is 12-15 ppm / DEG C which fits with the thermal expansion coefficient (12-18 ppm / DEG C) of a PCB. Flexure strength reaches up to 170-240 MPa, Young modulus is 50-70 GPa, mechanical property is excellent, and problems such as thermal expansion mismatch, etc. can be completely overcome. Meanwhile, the material has small dielectric constant, low loss and stable properties, and can meet requirements of high density packaging. In addition, the preparation technology is simple, mature, energy-saving and efficient, meets requirements of industrial production, and is convenient for batch production and promotion and application.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite as well as preparation method and application thereof

The invention discloses an ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite as well as a preparation method and an application thereof. The preparation method of the ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite comprises the following steps: S1, preparing Si-B-C-N-Zr powder; S2, performing surface modification treatment on fiber to obtain modifiedfiber; S3, mixing the modified fiber with the Si-B-C-N-Zr powder to obtain composite powder; S4, performing hot pressing and sintering on the composite powder to prepare the ablation-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite. The prepared ablative-resistant fiber toughened Si-B-C-N-Zr ceramic matrix composite has good microstructure and higher fracture toughness, mechanical property and ablative resistance, used raw materials are widely sourced and low in price, the preparation process is simple and mature, the preparation period is short, all the steps can be realized with existing technologies and equipment, and the composite is suitable for industrial production.

Owner:HARBIN INST OF TECH

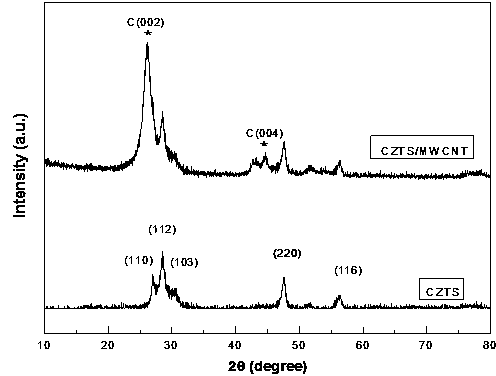

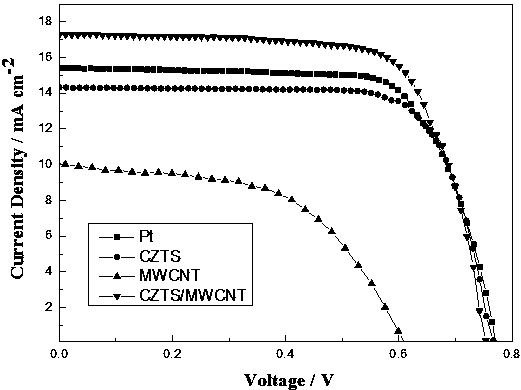

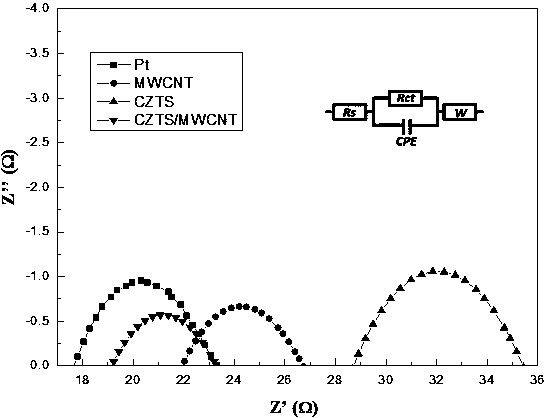

Cu2ZnSnS4 / MWCNT nano composite counter electrode for dye-sensitized solar cell and preparation method thereof

InactiveCN103794373AThe preparation process is simple and safeLow cost of preparationMaterial nanotechnologyElectrolytic capacitorsIonSolvent

The invention relates to a Cu2ZnSnS4 / MWCNT nano composite counter electrode for a dye-sensitized solar cell and a preparation method thereof. The method comprises following steps that: (1) a hot solvent method is used to synthesize a Cu2ZnSnS4 nanoparticle with a diameter of 200 to 300 nanos; (2) an MWCNT is immersed in a sulfuric acid and nitric acid mixed solution, so as to improve dispersibility of the mixed solution; (3) a Cu2ZnSnS4 / MWCNT nano composite material is stirred and carries out ultrasonic processing so that the composite material is mixed evenly, and the Cu2ZnSnS4 / MWCNT is dissolved in deionized water and forms "ink" by the ultrasonic processing; and (4) a spinning coating method is used so that black "ink" is coated on a conductive substrate, and then the Cu2ZnSnS4 / MWCNT composite counter electrode is obtained by annealing in 450 to 550 DEG C for 0.5 to 2 hours. According to the method, the Cu2ZnSnS4 / MWCNT having good corrosion resistance serves as the counter electrode of the dye-sensitized solar cell, so as to achieve the large surface area, good catalytic and conductive properties, and low production cost; and the battery which is manufactured with adoption of the preparation method, has the same photoelectric conversion efficiency as the battery based on a conventional Pt electrode, is suitable for application to the dye-sensitized solar cell, and is beneficial to the industrialization development of the dye-sensitized solar cell.

Owner:CHINA UNIV OF MINING & TECH

Healthcare fruit and vegetable composite beverage

InactiveCN106107287AComfortable tasteRelieve stressFood ingredient functionsDepressive symptomsPear juice

The invention belongs to the technical field of beverage processing and relates to a healthcare fruit and vegetable composite beverage. The healthcare fruit and vegetable composite beverage is made from snow pear juice, watermelon juice, aloe juice, Maca juice, okra juice, banana juice and honey. Various fresh fruit and vegetable raw materials are squeezed through a physical method to obtain liquid juice, and the liquid juice is scientifically mixed into the beverage. The beverage is comfortable in taste, has the effects of quenching thirst and soothing the nerves, and can relieve depressive symptoms; the formula is scientific and reasonable, no toxic or side effect exists, the preparation process is simple and mature, the intended population range is wide, the retention cycle is long, the taste is good, and rich nutrients are obtained.

Owner:佛山泓乾生物科技有限公司

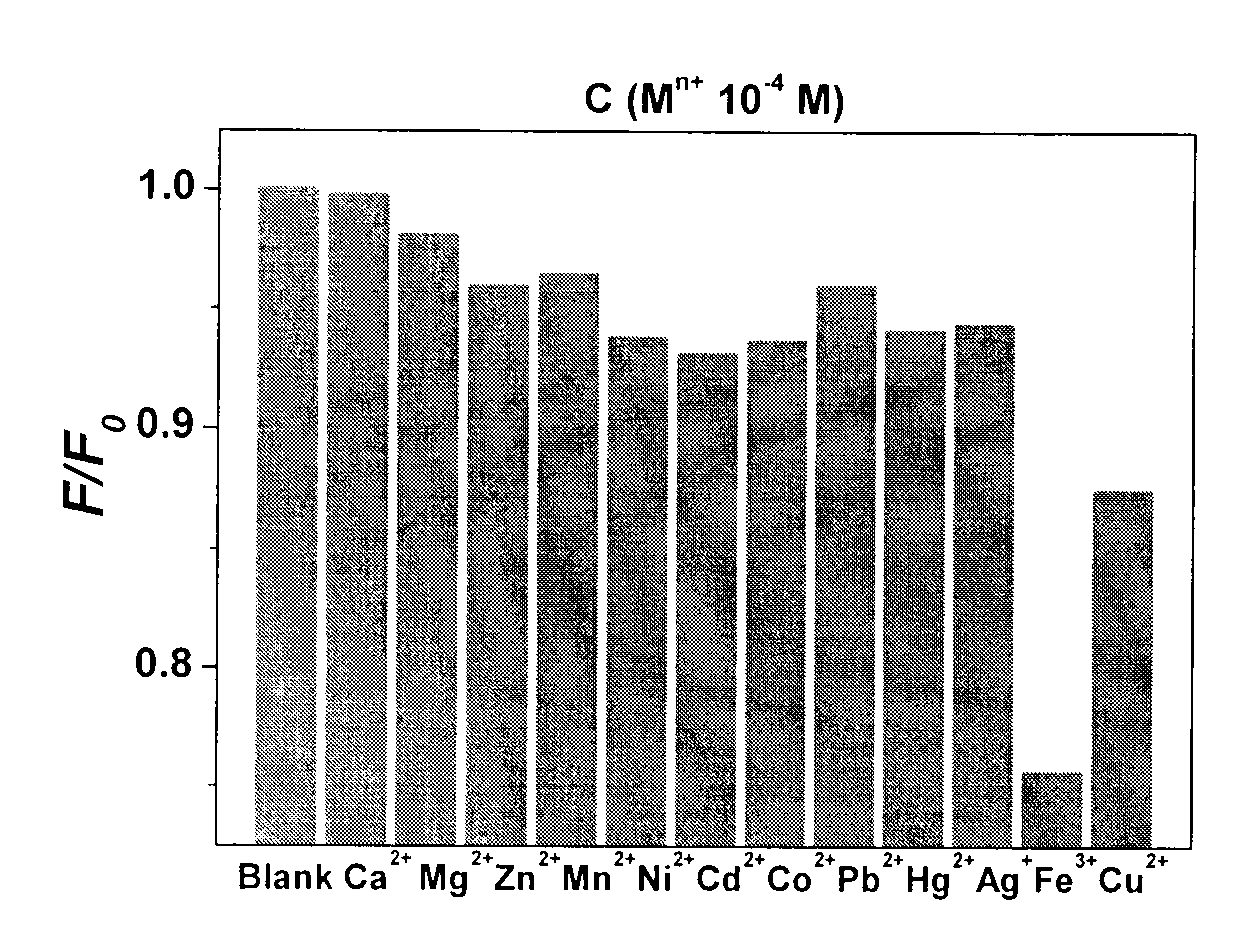

Preparation method of stable fluorescent carbon

InactiveCN102703070ARaw materials are cheap and easy to getThe preparation process is simple and matureNano-carbonFluorescence/phosphorescenceDistilled waterAqueous solubility

The invention relates to a simple green preparation method of stable fluorescent carbon. The method comprises the following steps: mixing sweet rice wine and secondary distilled water and carrying out hydrothermal reaction at 140-180 DEG C to prepare aqueous solution of stable nano fluorescent carbon particle. The preparation method does not need special equipment and special reaction conditions, is simple in process, high in yield and environment-friendly, and is suitable to mass industrial production. The prepared nano fluorescent carbon particle has good water-solubility, high stability and can be directly applied to detection of metal Fe<3+> ions.

Owner:HENAN NORMAL UNIV

Etching fluid for silver nanowire conducting film and application method thereof

InactiveCN108048842AStable electrical conductivity on the surface of the filmLow resistivityStrong acidsElectromagnetic shielding

The invention provides etching fluid for a silver nanowire conducting film and an application method thereof. The etching fluid comprises, by mass percent, 10-30% of acetic acid, 5-10% of ammonia water, 10-20% of inorganic metallic salt, 6-16% of hydrogen peroxide, 3-15% of water-soluble polymer, 4% of silicon dioxide, 3% of carboxymethyl cellulose, 2-17% of ethylene glycol and 10-30% of deionizedwater. The silver nanowire conducting film prepared through the etching fluid has the characteristics of being stable in film surface conductivity, low in resistivity, high in light transmittance andstrong in adhesive force. The etching fluid is simple and mature in preparation technological process, simple in equipment, convenient to operate, low in cost and convenient to apply and popularize.Besides, the silver nanowire conducting film prepared through the etching fluid has the characteristics of being good in chemical stability and excellent anti-corrosive performance, does not contain strong acid or strong base, causes little environmental pollution, can be applied to the fields such as electromagnetic shielding and electronic circuits and has extensive application value.

Owner:TIANJIN BAOXINGWEI TECH

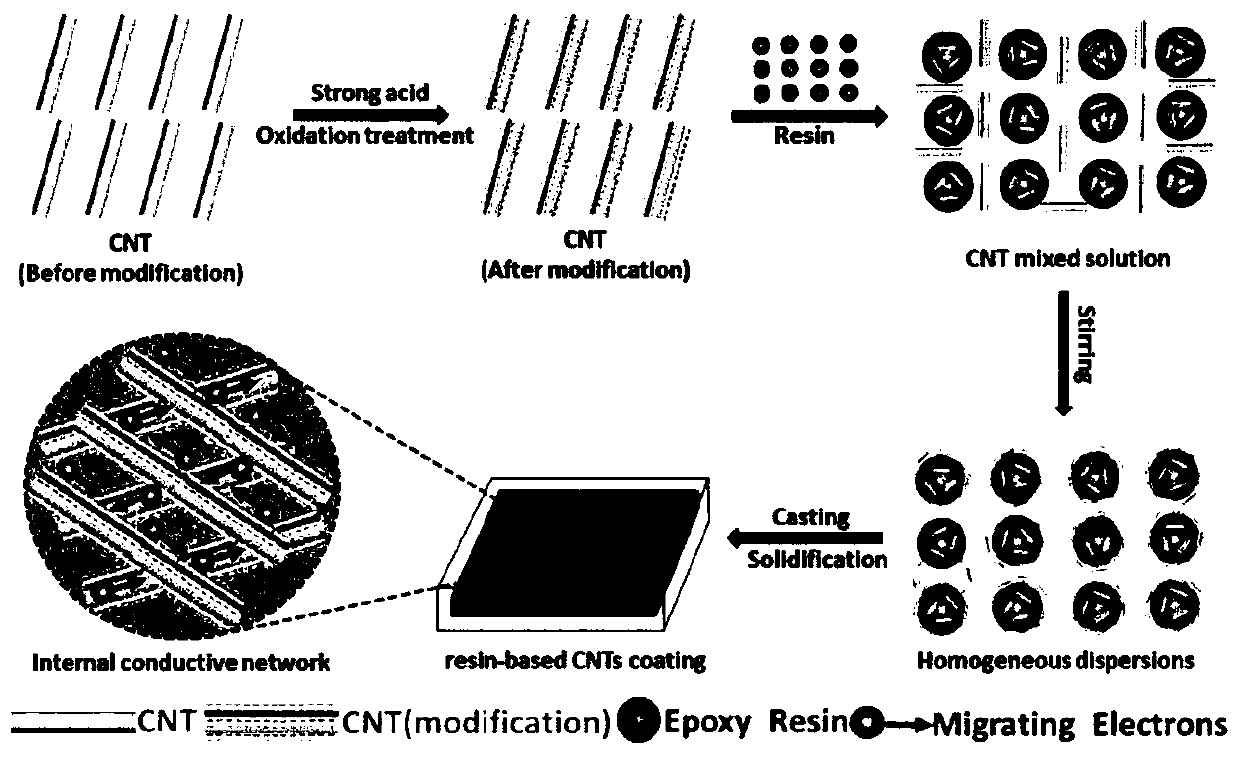

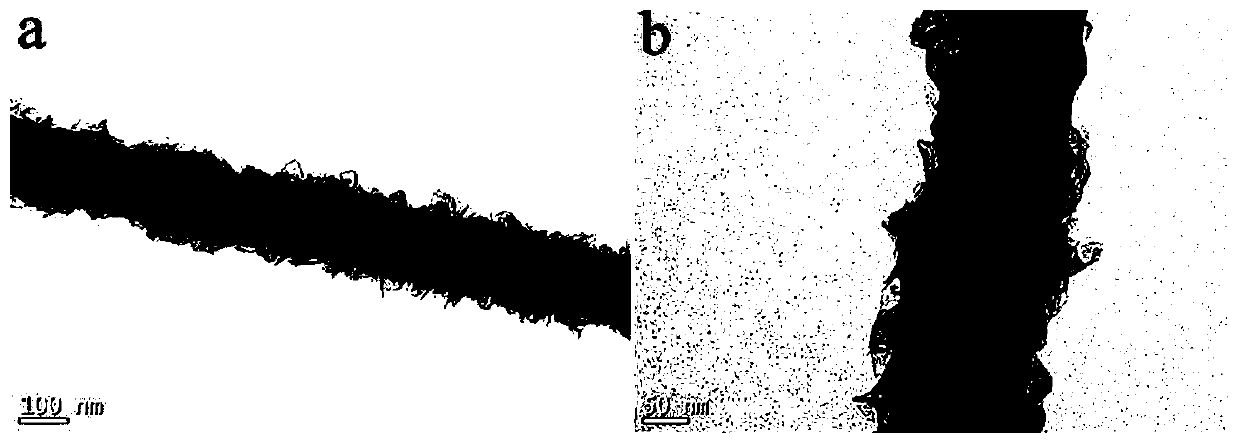

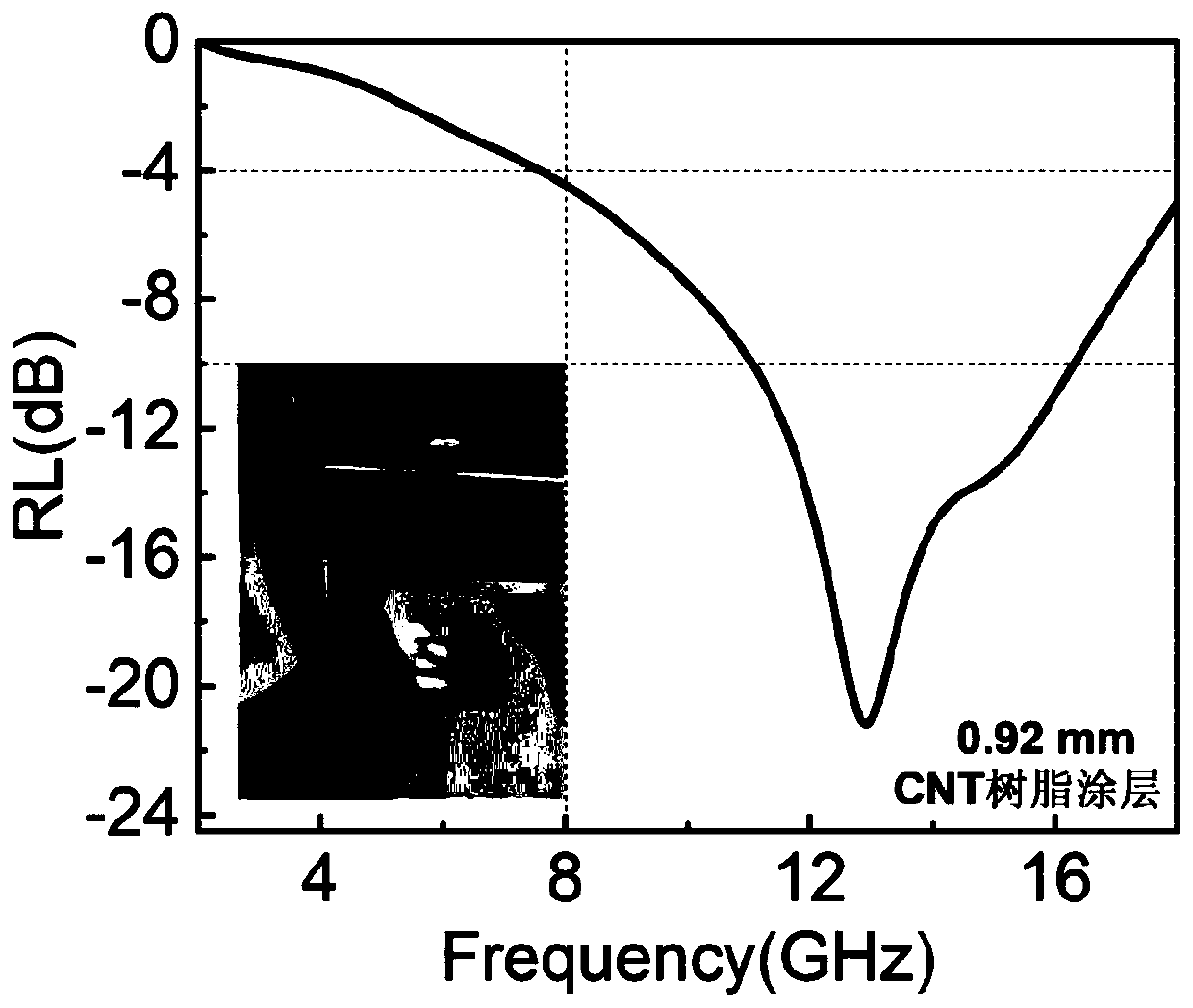

Preparation method of ultra-thin carbon nano tube wave-absorbing coating material

ActiveCN110423535AObvious Thickness AdvantageRealize full-band ultra-thin absorptionConjugated diene hydrocarbon coatingsRadiation-absorbing paintsReflection lossModified carbon

The invention discloses a preparation method of an ultra-thin carbon nano tube wave-absorbing coating material. According to the preparation method, surface strong oxidation treatment is carried out on a carbon nano tube by a method of mixing strong acid with a strong oxidant, and a modified carbon nano tube with a special ''wool-shaped'' surface appearance is prepared. Different high polymer materials are selected as a matrix, and the ultra-thin broadband carbon nano tube wave-absorbing coating material is obtained by adjusting the proportion relation between the content of an absorbent and the high polymer materials. The coating material prepared by the method overcomes the defects of large thickness, large mass, narrow absorption frequency band, complex preparation process and the likeof a conventional wave-absorbing coating material. When the thickness of the coating is 1.0 mm or below, full-band absorption of the X wave band and the Ku wave band of radar waves of -4dB or below can be realized, and the frequency width of reflection loss less than -10dB can reach 5.23GHz.

Owner:西安纳科新材料科技有限公司 +1

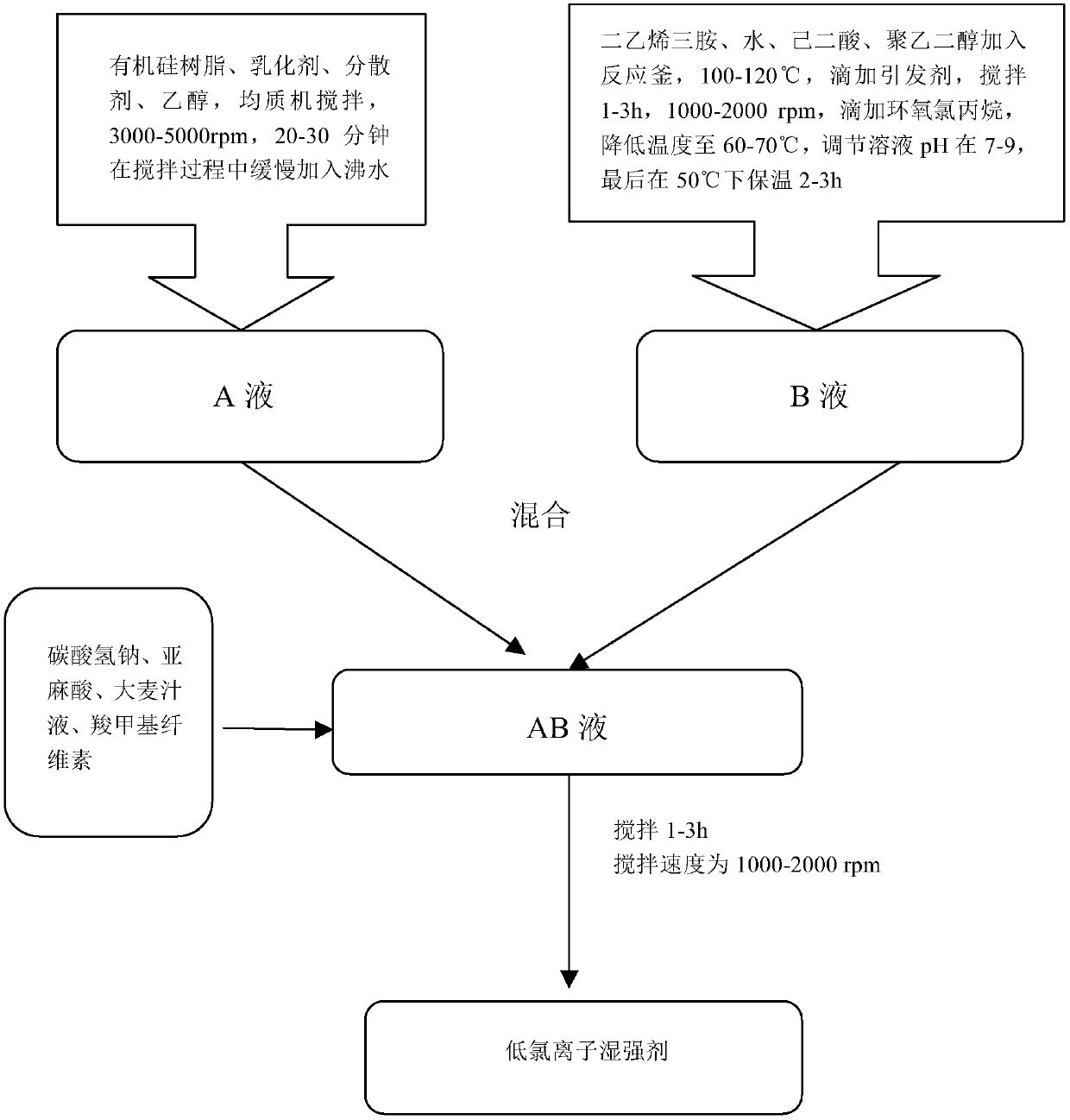

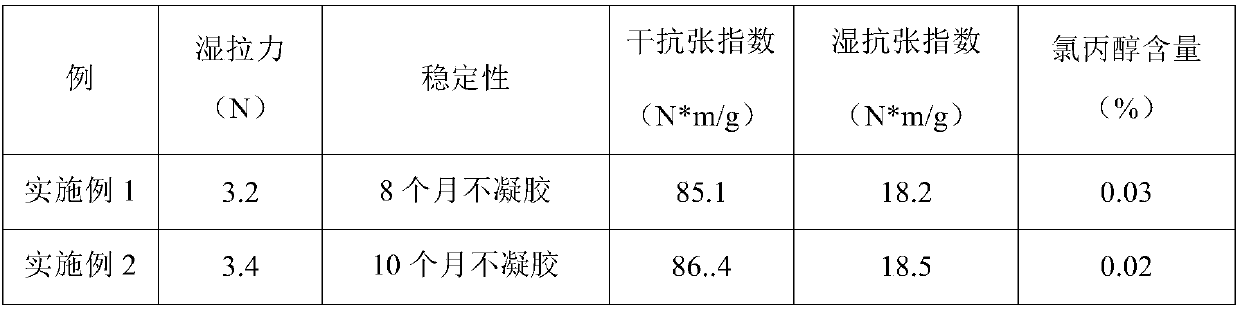

Low chloride ion wet strength agent and preparation method thereof

InactiveCN109610227AThe preparation process is simple and matureLow production cost and environmental protectionVegetable material additionReinforcing agents additionSodium bicarbonatePolyethylene glycol

The invention discloses a low chloride ion wet strength agent and a preparation method thereof. The preparation method comprises the following steps: (1) preparation of liquid A: adding organic silicone resin, emulsifier, dispersant and ethanol to a beaker, stirring by a homogenizer, slowly adding boiling water in the stirring process to obtain liquid A; (2) preparation of liquid B: adding diethylene triamine, water, adipic acid and polyethylene glycol into a reaction kettle, slowly raising the temperature to 100-120 DEG C, while slowly adding initiator dropwise, fully stirring for 1-3 hours at the stirring speed of 1000-2000 rpm, then slowly adding epichlorohydrin dropwise, lowering that temperature to 60-70 DEG C, adding appropriate dilute alkali, adjusting the pH of the solution to 7-9,finally, performing heat preservation at 50 DEG C for 2-3 hours to obtain solution B; (3) mixing A with B: mixing A with B, adding sodium bicarbonate, linolenic acid, barley juice, carboxymethyl cellulose, stirring for 1-3 hours at the stirring speed of 1000-2000 rpm, that is the low chloride ion wet strength agent solution can be obtained.

Owner:山东同创精细化工有限公司

Heterojunction array based ultraviolet detector and manufacturing method thereof

InactiveCN106057960AFast shippingEasy to separateMaterial nanotechnologyFinal product manufactureQuantum efficiencyHeterojunction

The invention discloses a heterojunction array based ultraviolet detector and a manufacturing method thereof. The detector comprises a substrate and a conductive film; an Sm2O3@ZnO heterojunction array which is used as an ultraviolet absorbing layer and at least one N-type ohmic electrode are arranged on the conductive film; at least one P-type ohmic electrode is arranged on the Sm2O3@ZnO heterojunction array; and the Sm2O3@ZnO heterojunction array is composed of a ZnO nano-tube array and an Sm2O3 nano-wire filled in the ZnO nano-tube. The core structure of the detector provided by the invention is the heterojunction array consisting of the ZnO nano-tube array and the Sm2O3 nano-wire penetrating the ZnO nano-tube; the usage rate of a photo-generated carrier can be sufficiently improved, and the heterojunction array based ultraviolet detector has the advantages of high external quantum efficiency and flexibility, small volume and the like.

Owner:兰建龙

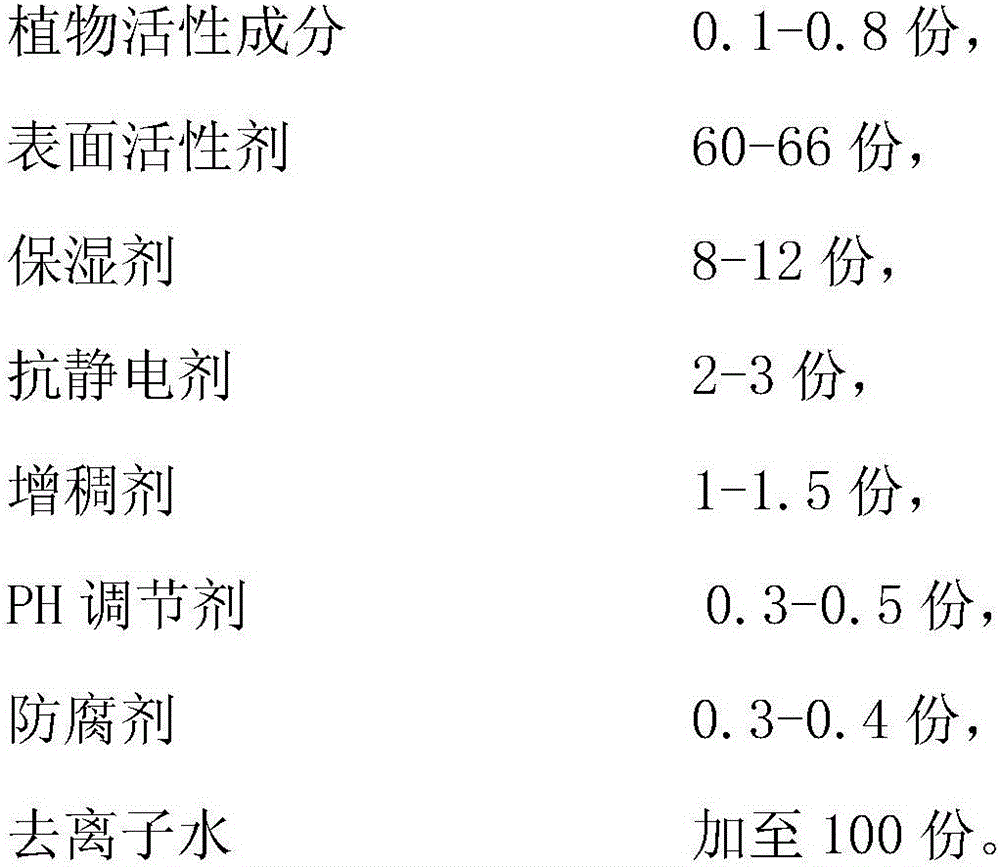

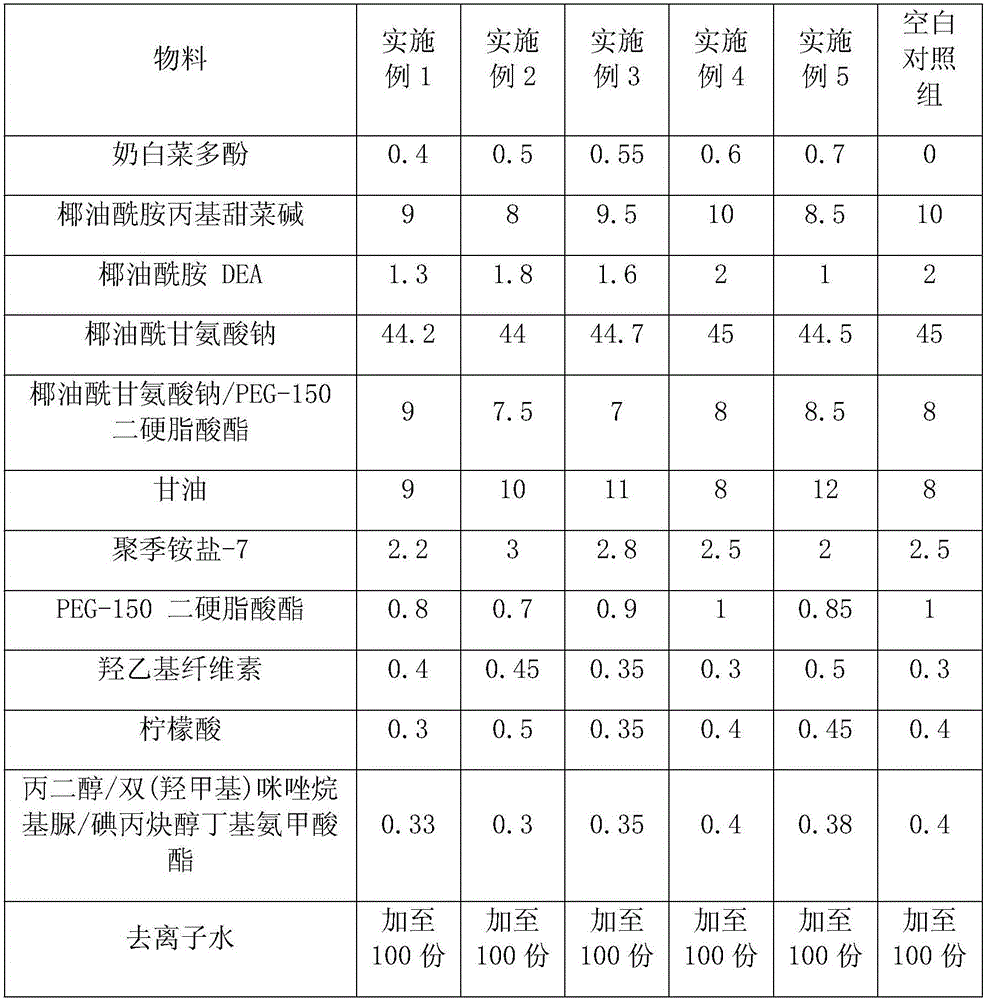

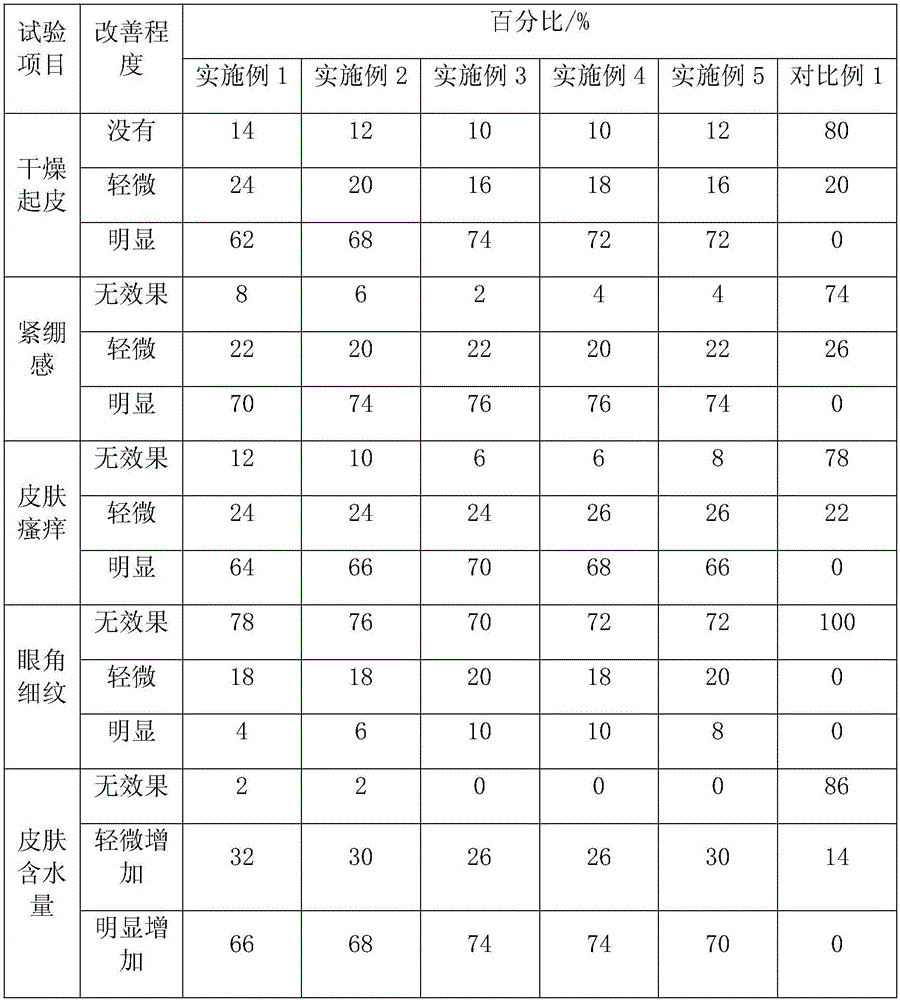

Moisturizing cosmetic capable of refining pores

InactiveCN106619300AThe preparation process is simple and matureLow priceCosmetic preparationsToilet preparationsFine lineCuticle

The invention discloses a moisturizing cosmetic capable of refining pores. The moisturizing cosmetic is prepared from the following components in parts by weight: 0.1-0.8 part of plant active ingredients, 60-66 parts of a surfactant, 8-12 parts of a humectant, 2-3 parts of an antistatic agent, 1-1.5 parts of a thickener, 0.3-0.5 part of a pH modifier, 0.3-0.4 part of a preservative and deionized water added to 100 parts. The moisturizing cosmetic is capable of providing the skin surface with moisture and maintaining normal vital movement of epidermis cells, so that formation of a healthy sebum membrane on the skin is facilitated and the moisture content of the skin is effectively kept; coarse pores can be converged and refined, the evaporation capacity of the moisture in the skin is reduced and the moisture content of the skin is kept, so that the skin is moisturized, fine lines of canthus are reduced, the phenomena of skin dryness and peeling, tension and cutaneous pruritus are improved, skin cells have certain wettability even if a cold and dry environment exists and the phenomenon of extreme hydropenia is avoided.

Owner:聚吉减肥塑形科学技术研究院(广州)有限公司

Preparation method of novel three-dimensional greening integral culture medium

The invention relates to a preparation method of a novel three-dimensional greening integral culture medium. The preparation method includes following steps: sequentially adding phenolic resin, Tween80 and ethylene glycol into a reaction container according to different using amounts, and stirring well at 35-40 DEG C; adding n-pentane and p-toluenesulfonic acid into a reaction container, and stirring well at 35-40 DEG C; pouring two mixed solutions into a reaction container, stirring well, adding sawdust stepwise, and stirring well; after reaction is completed, cooling and forming for a period of time to obtain the three-dimensional greening integral culture medium. A new preparation method is provided for the three-dimensional greening integral culture medium, and the culture medium hasthe advantages of low volume weight, long storage time, high hydroscopicity, certain nutrition and partial degradability.

Owner:福州乐亿生态科技股份有限公司

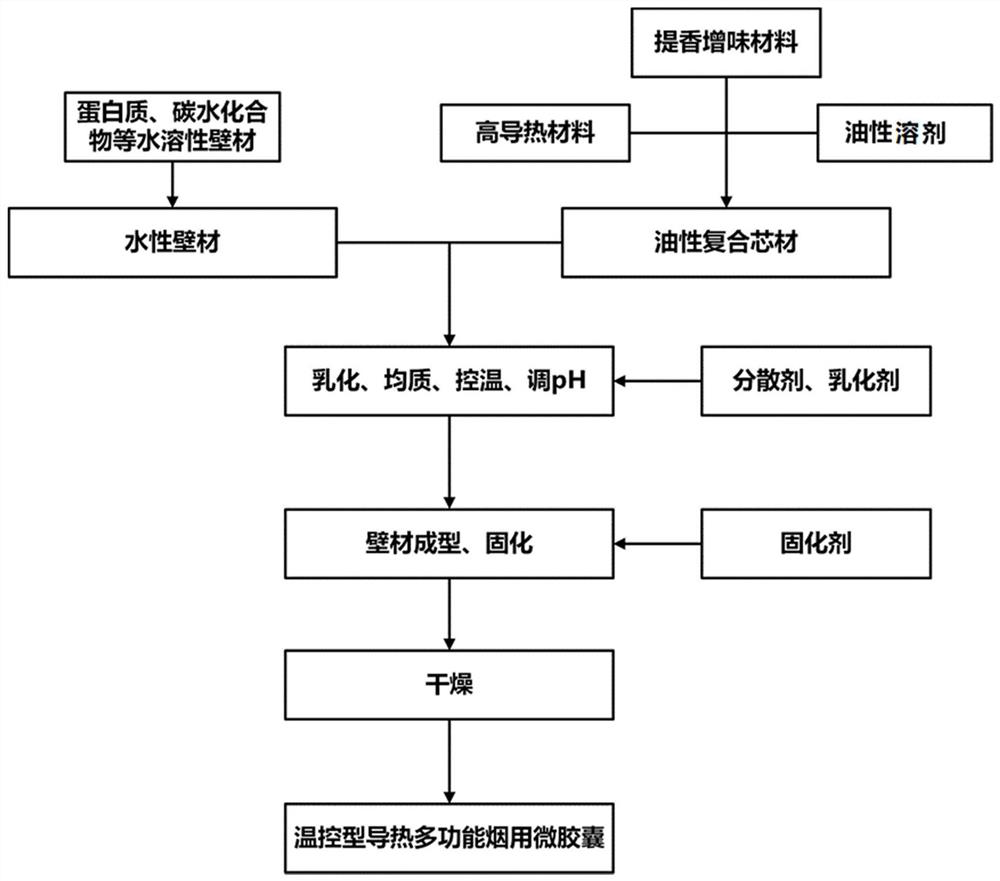

Temperature control type heat conduction multifunctional cigarette microcapsule and preparation method thereof

PendingCN113170920AThe preparation process is simple and matureSimple preparation processTobacco preparationCigar manufacturePolymer scienceOrganic chemistry

The invention relates to the technical field of cigarettes, in particular to a temperature control type heat conduction multifunctional cigarette microcapsule and a preparation method thereof. According to the invention, a composite core material containing a heat conduction material and a oily solvent and a wall material are subjected to condensation and curing reaction to prepare the microcapsule, the microcapsule can be directly added in the preparation process of tobacco sheets / tobacco shreds or in a finished product, and in the low-temperature cigarette smoking process, when the temperature reaches 160 DEG C or above, the wall material of the microcapsule is successively fused and broken, and releasing composite core material is released. The heat conduction material and the oily solvent can improve the heat transfer effect, and meanwhile, the oily solvent in the composite core material and the flavor-enhancing and aroma-enhancing substance which can be selectively added can be volatilized due to heating, so that the sensory quality during smoking is enhanced.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

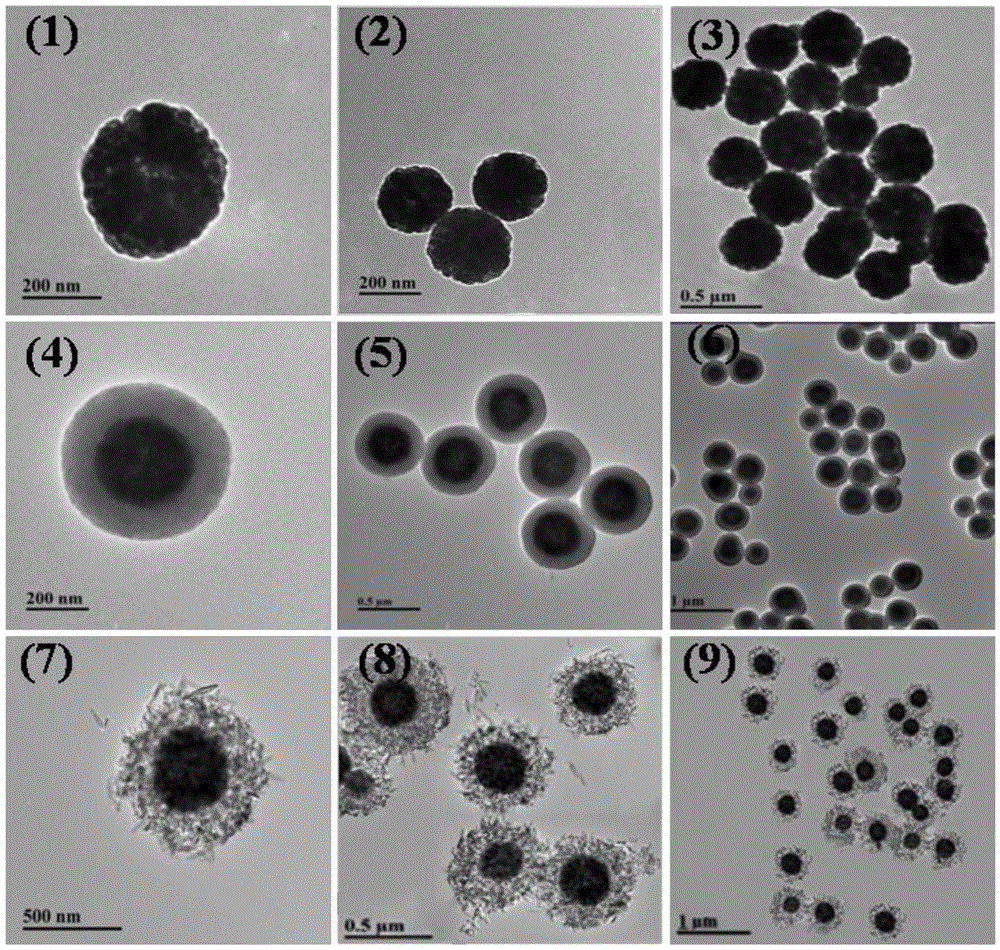

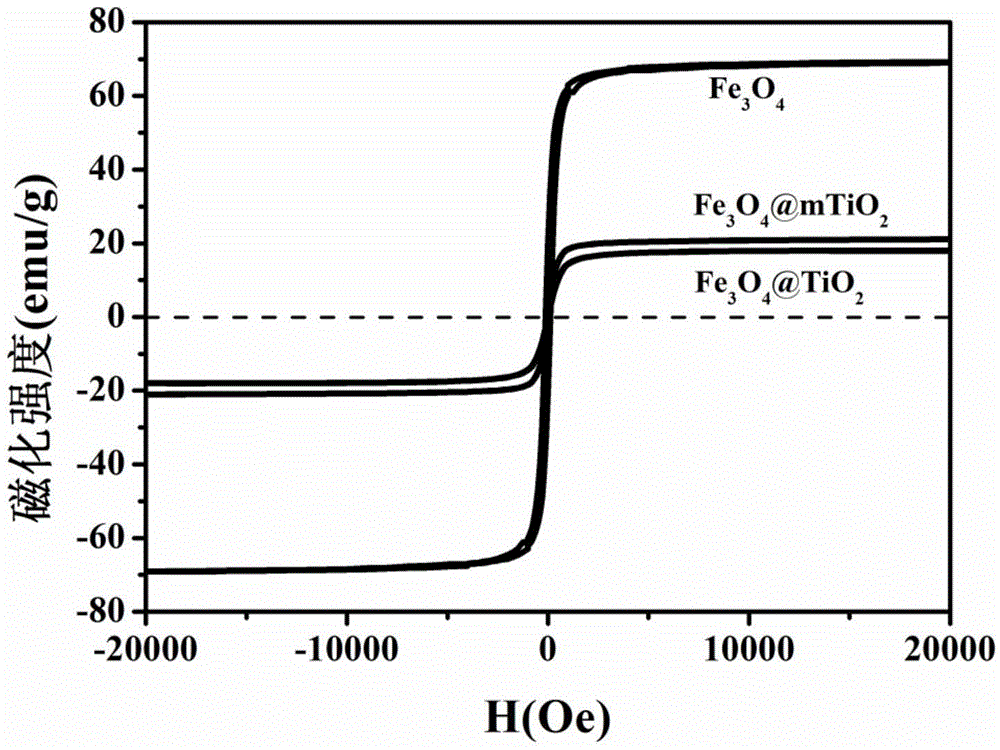

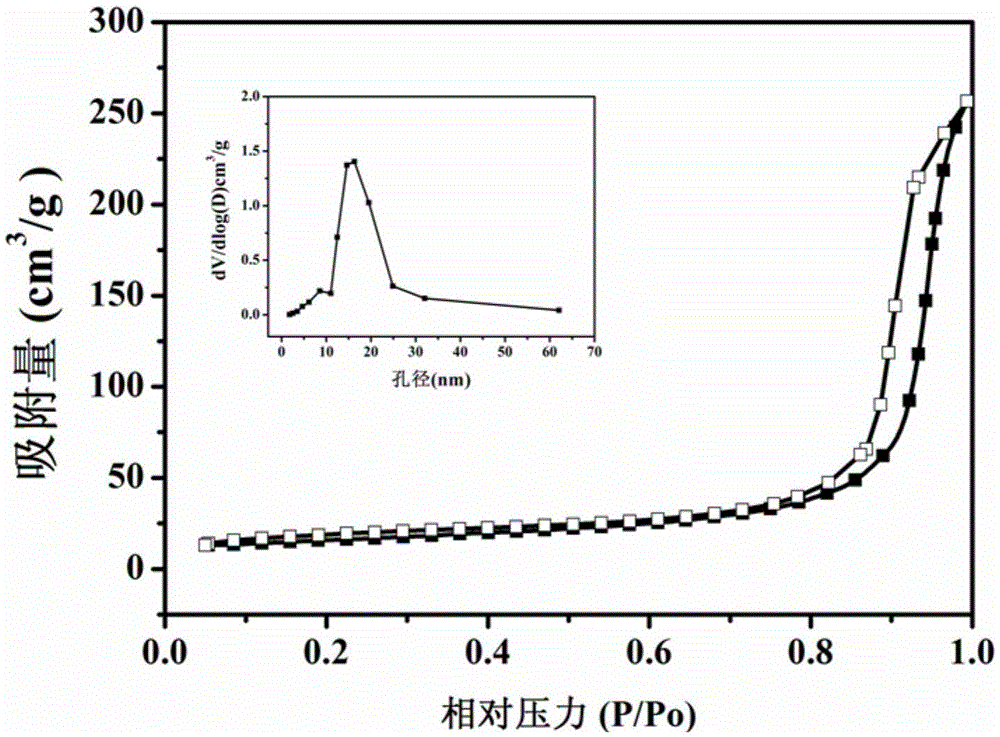

Application of Fe3O4/mTiO2 magnetic mesoporous nanometer material in degradation of pesticide

InactiveCN105478122AThe preparation process is simple and matureLow priceWater/sewage treatment by irradiationWater treatment compoundsMaterials preparationUltraviolet lights

The invention discloses application of a Fe3O4 / mTiO2 magnetic mesoporous nanometer material in degradation of pesticide and belongs to the technical field of micro-nanometer photocatalytic materials. The Fe3O4 / mTiO2 magnetic mesoporous nanometer material is used as a photocatalyst to be applied to adsorption and degradation of organophosphorus pesticide; the Fe3O4 / mTiO2 magnetic mesoporous nanometer material relies on surface mesoporous TiO2 to absorb the organophosphorus pesticide to the TiO2 mesoporous surface; then, under the irradiation of ultraviolet light, TiO2 active sites are excited to degrade absorbed organophosphorus molecules to generate low-toxicity or even non-toxic products; after the reaction, the photocatalyst can be adsorbed and separated through a magnet. The operation is simple and easy to perform. By applying the Fe3O4 / mTiO2 magnetic mesoporous nanometer material to adsorption and degradation of the organophosphorus pesticide, the application is novel and advanced, practical significance is achieved, and the material preparation process is simple and mature, easy to operate, low in cost and free of secondary pollution.

Owner:JIANGNAN UNIV

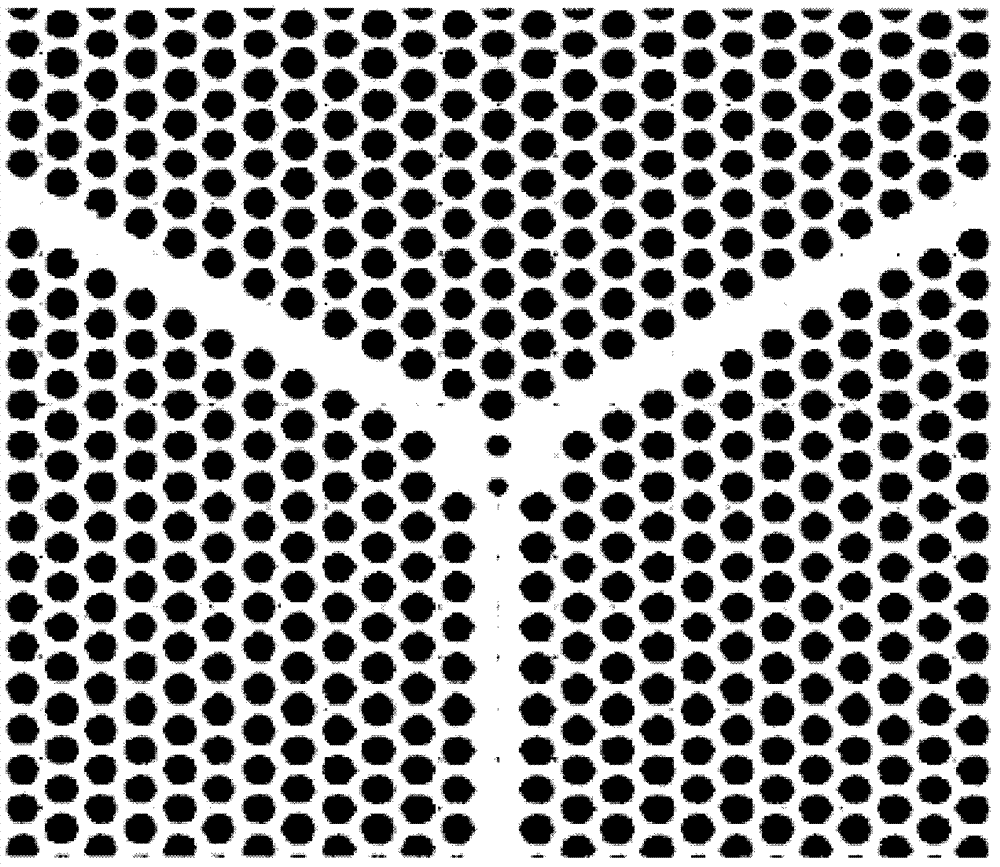

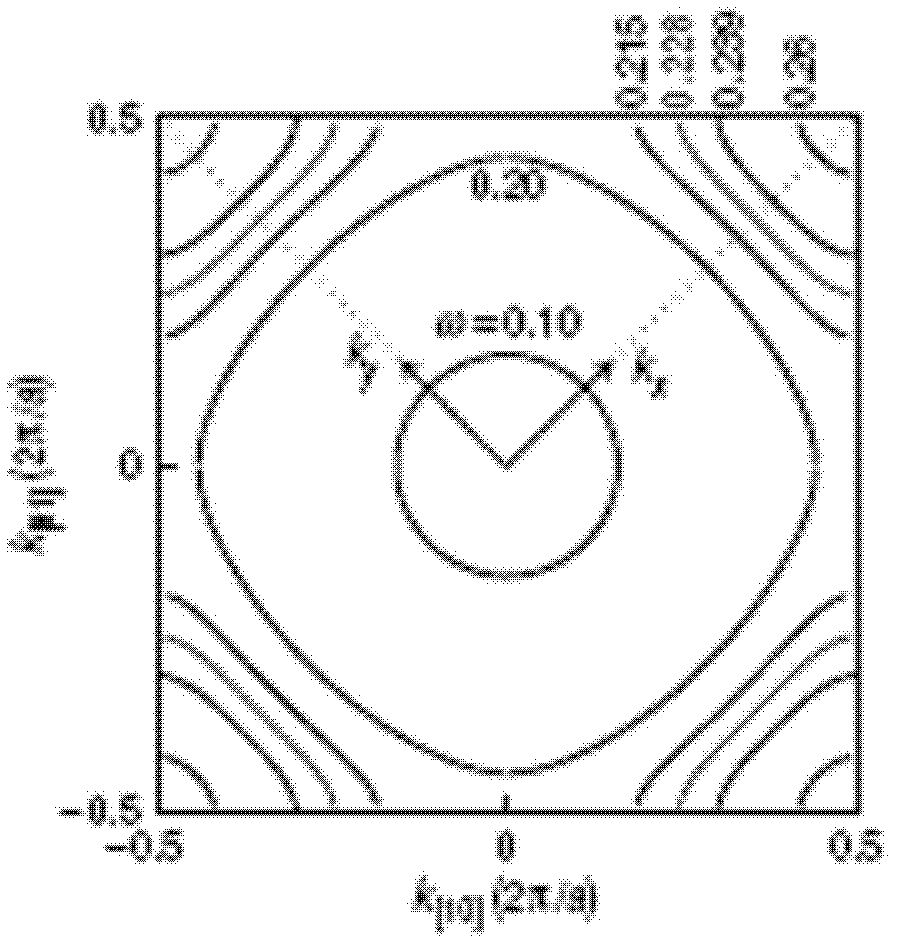

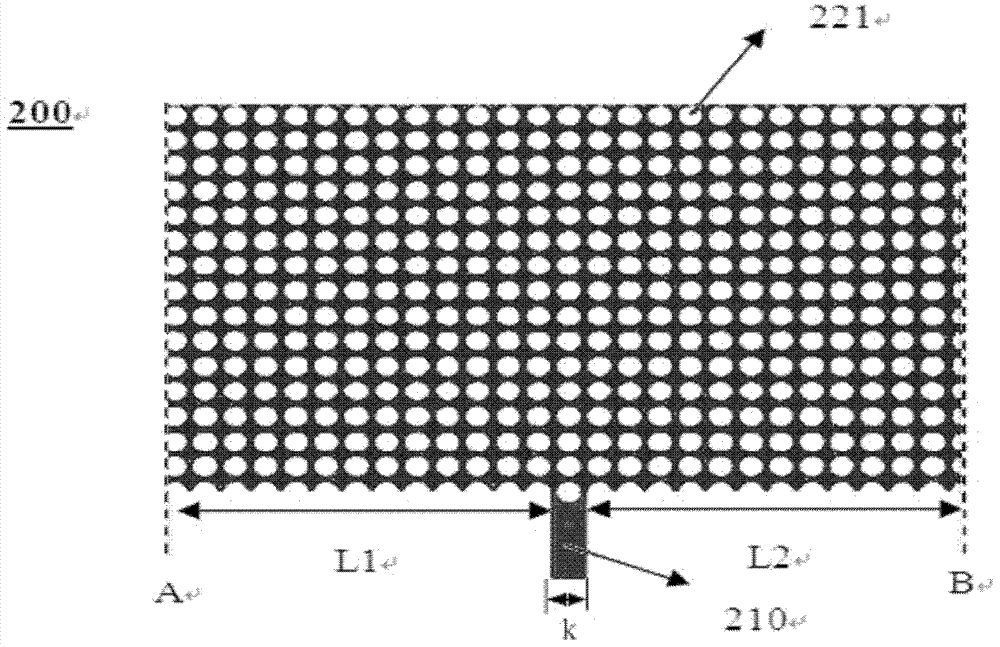

Photonic crystal beam splitter

InactiveCN102789023AShorten the lengthLarge production toleranceOptical light guidesPhotonic crystalBeam splitting

The invention relates to a photonic crystal beam splitter which realizes the beam splitting and propagating of the inputted optical signals by the auto-collimation effect of the SOI (silicon on insulator) based two-dimensional flat air-hole photonic crystal, belonging to the field of optical technology of the semiconductors. The photonic crystal beam splitter comprises an SOI substrate, an air hole area and an SOI stripe-shaped waveguide; the air hole area is formed on the top-layer silicon of the SOI substrate by etching silicon; the SOI stripe-shaped waveguide is used for connecting the air hole area with the external optical fiber or other devices; the air holes formed by etching silicon in the air hole area are arrayed on the top-layer silicon of the SOI substrate like square crystal lattices; the depth of the air holes is equal to the thickness of the top-layer silicon of the SOI substrate; and the SOI stripe-shaped waveguide is the inputting waveguide of the beam-splitter and keeps a certain distance with both the air hole area and two borders which are parallel to the inputting waveguide. The length of the beam splitting area of the beam splitter can be controlled with 10mum, thus the overall length of the device is reduced greatly, and the structure is more compact. In addition, the photonic crystal beam splitter has large preparation tolerance and more flexible design and can be more widely used for the future photonic chip.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A kind of conductive paint and preparation method thereof

ActiveCN103992678BStrong adhesionHigh hardnessAnti-corrosive paintsElectrically-conductive paintsCelluloseTributyl citrate

The invention relates to the technical field of conductive coatings, particularly to a conductive coating and a preparation method thereof. The conductive coating comprises the following raw materials in percentage by weight: 50 to 70% of absolute ethyl alcohol, 2 to 5% of terpilenol, 3 to 8% of dimethylacetamide, 1 to 3% of acetyl tributyl citrate, 2 to 8% of organic silicone oil, 1 to 5% of polyethylene glycol 400, 2 to 3% of span 85, 1.5 to 3% of ethyl cellulose, 0.5 to 2% of polyimide resin, 0.5 to 1.5% of polyester resin, 3 to 8% of silver powder of 20-35 nanometers, and 10 to 18% of silver powder of 150-300 nanometers. The conductive coating provided by the invention has the characteristics of stable surface conductivity of the formed film, low resistivity, high light transmittance, strong adhesive force, high temperature resistance and corrosion resistance; the formed film has light transmittance of up to more than 90%, and surface hardness of not less than 2H. The preparation process, provided by the invention, is simple and mature, so that the preparation process facilitates popularization and application, and the production cost is low.

Owner:山东七维新材料有限公司

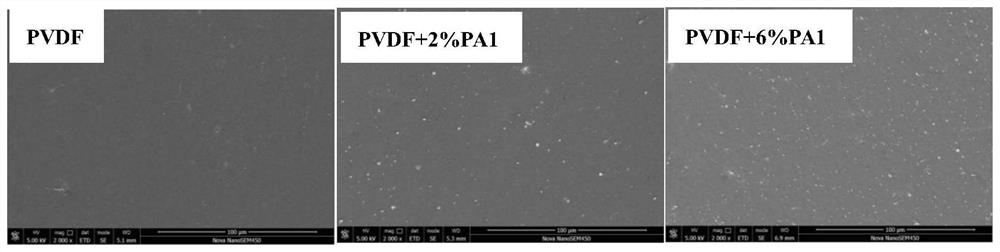

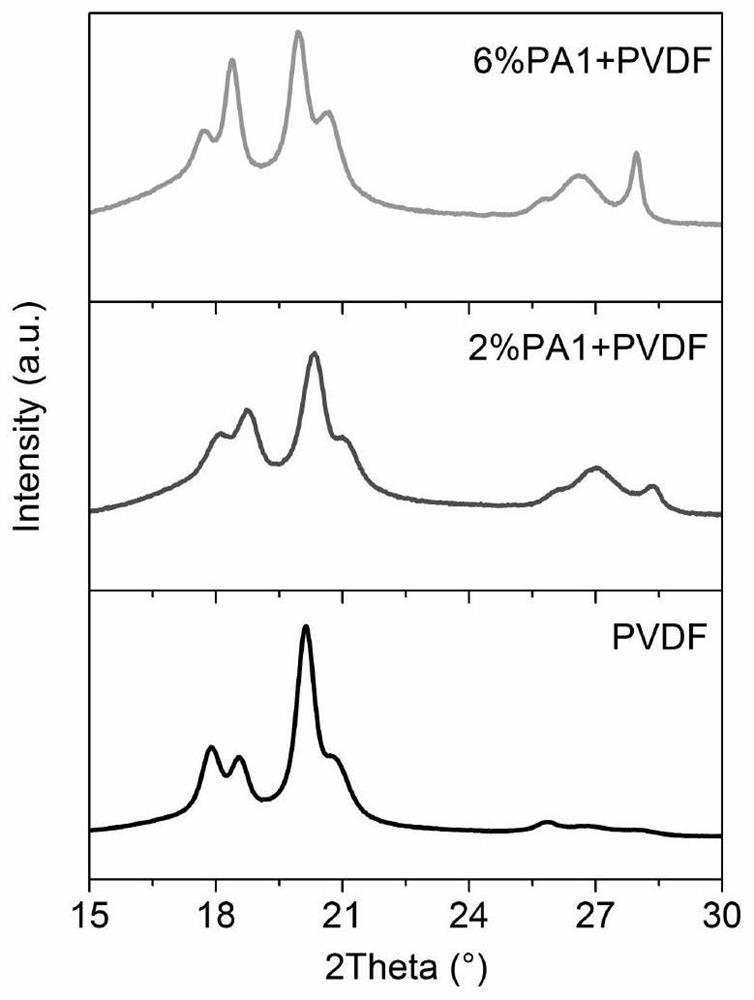

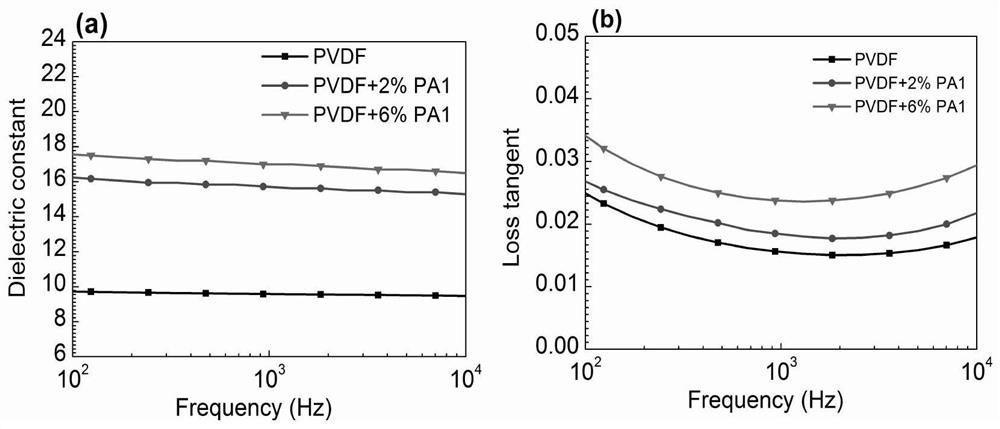

Nylon 1/polyvinylidene fluoride composite dielectric film and preparation method thereof

The invention provides a nylon 1 / polyvinylidene fluoride composite dielectric film and a preparation method thereof, and relates to the technical field of composite materials. The film is prepared from the following components in percentage by weight: 80 to 99 percent of polyvinylidene fluoride and 1 to 20 percent of nylon 1. The invention further provides a preparation method of the nylon 1 / polyvinylidene fluoride composite dielectric film. The preparation method comprises the following steps: mixing polyvinylidene fluoride and nylon 1, and mixing on a torque rheometer at 180-200 DEG C for 10-20 minutes; and carrying out hot pressing on the mixed product on a press vulcanizer at 180-200 DEG C for 10-20 minutes, and maintaining the pressure at room temperature for 3-10 minutes to obtain the nylon 1 / polyvinylidene fluoride composite dielectric film. The dielectric constant of the polyvinylidene fluoride is improved, the dielectric loss of the polyvinylidene fluoride is kept at a low level, various problems caused by poor compatibility are reduced, and therefore the functional characteristics of the polyvinylidene fluoride are improved.

Owner:都江堰市天兴硅业有限责任公司

A kind of nano-silver flexible conductive film and preparation method thereof

ActiveCN103992495BStable electrical conductivity on the surface of the filmLow resistivityConductive layers on insulating-supportsPretreated surfacesCelluloseAdhesive

The invention relates to the technical field of conductive films, and in particular to a nano-silver flexible conductive film and a preparation method thereof. The nano-silver flexible conductive film includes a PET substrate layer with a corona-treated surface, and a conductive paint layer is provided on the surface of the PET substrate layer. , the conductive coating layer includes the following raw materials by weight: 50-75% absolute ethanol, 2-5% terpineol, 1-3% acetyl tributyl citrate, 2-8% adhesive, 1-5% Polyethylene glycol 400, 2-3% Sipan 85, 1.5-3% ethyl cellulose, 20-40 nanometer silver powder is 3-8%, 150-450 nanometer silver powder is 10-18%. The nano-silver flexible conductive film of the present invention has the characteristics of stable film-forming surface conductivity, low resistivity, high light transmittance, and strong adhesion. The preparation process of the nano-silver flexible conductive film is simple and mature, the coating equipment is simple, and the operation is convenient. , low cost, easy to promote and apply.

Owner:杨佳雯

Preparation method of natural fruit and vegetable compound beverage

InactiveCN104544404AComfortable tasteThe formula is scientific and reasonableNatural extract food ingredientsFood ingredient functionsThirstSugar cane

The invention belongs to the technical field of beverage processing, and relates to a preparation method of a natural fruit and vegetable compound beverage. The compound beverage is prepared from sugarcane, cucumber, celery, pumpkin, gumbo and banana by juicing with a physical method, mixing the juice with honey and sterilizing. Fresh fruits and vegetables are used as raw materials, so that the compound beverage has comfortable mouthfeel, has the effects of quenching thirst, soothing nerves and relieving depression; the compound beverage is scientific and reasonable in formula, and does not have toxic or side effect; the preparation process is simple and mature; and the compound beverage is suitable for mass people and has rich nutrition.

Owner:QINGDAO UNIV

Candy capable of quitting smoking and treating bronchitis and pneumonia and preparation method

InactiveCN105558229ACan cure bronchitisPneumonia can be curedNervous disorderConfectioneryMentha spicataChrysanthemum Flower

The invention discloses a candy capable of quitting smoking and treating bronchitis and pneumonia and a preparation method. The candy is prepared from the following raw materials in parts by weight: 10 to 20 parts of mulberry leaves, 10 to 20 parts of chrysanthemum flower, 5 to 10 parts of Herba Menthae, 10 to 20 parts of fructus forsythiae, 10 to 20 parts of almond, 10 to 20 parts of radix platycodi, 10 to 30 parts of rhizoma phragmitis, 5 to 10 parts of raw licorice root, 10 to 20 parts of buffalo horn, 5 to 10 parts of radix scrophulariae, 5 to 10 parts of achyranthes aspera, 5 to 10 parts of fructus tribuli, 3 to 8 parts of accessories and 3 to 8 parts of a flavoring agent. The candy prepared by the preparation method has fragrance of smoke, and can effectively help crowds wanting to quit smoking; raw material compositions of the candy are based on scientific compatibility, and diseases related to bronchitis and pneumonia can be prevented and treated effectively while smoking is quitted; and the candy develops a new product field, and is worthy of popularization and application.

Owner:王金国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com