Nano coaxial-cable heterojunction array base ultraviolet detector and manufacturing method thereof

A technology of ultraviolet detectors and coaxial cables, which is applied to circuits, electrical components, microstructure technology, etc., can solve the problems of low colloidal particle filling rate, polycrystalline film grain boundaries and defect density hindering the diffusion of photo-generated electrons, photo-generated electrons-air Problems such as limited separation of acupoint pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

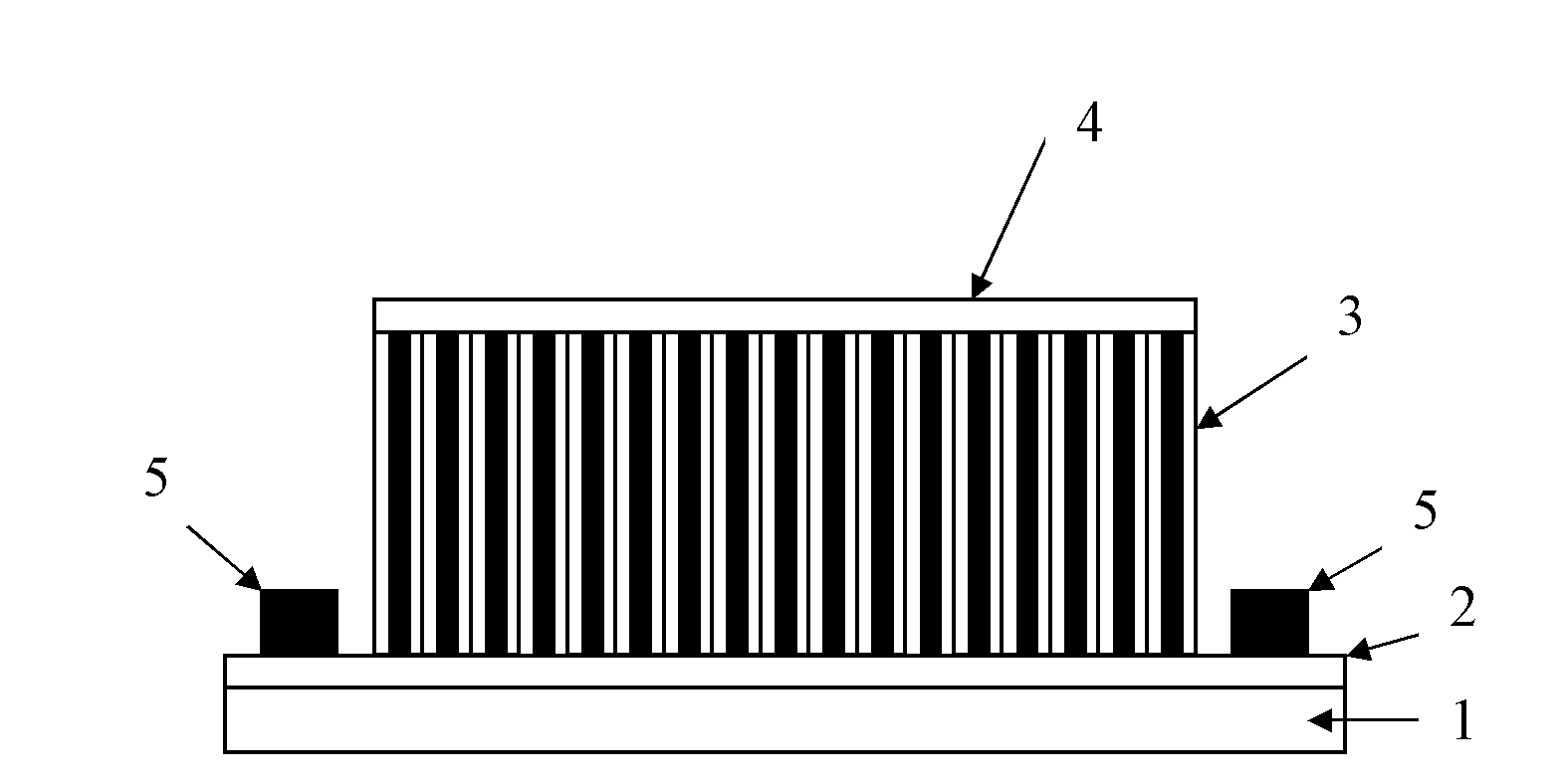

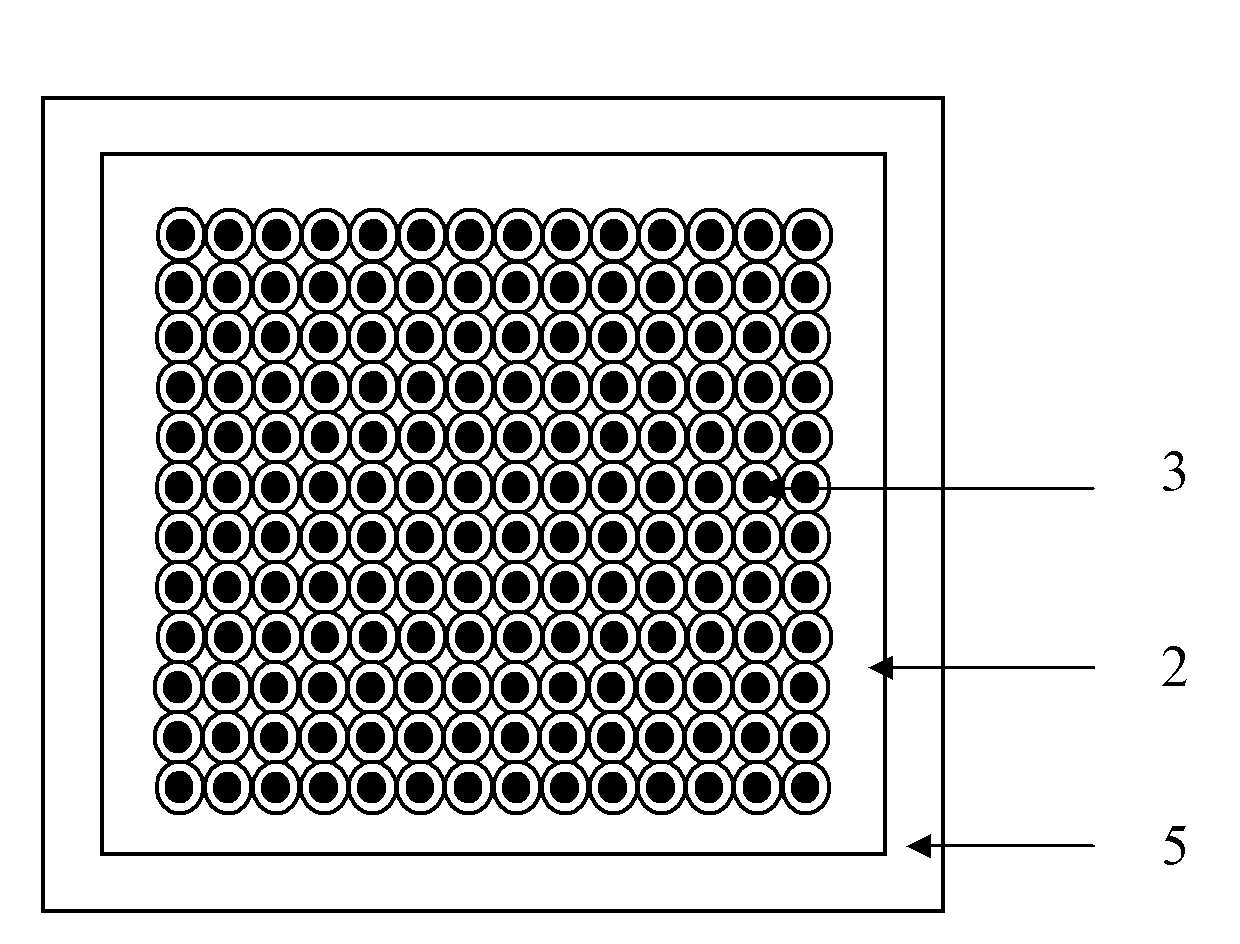

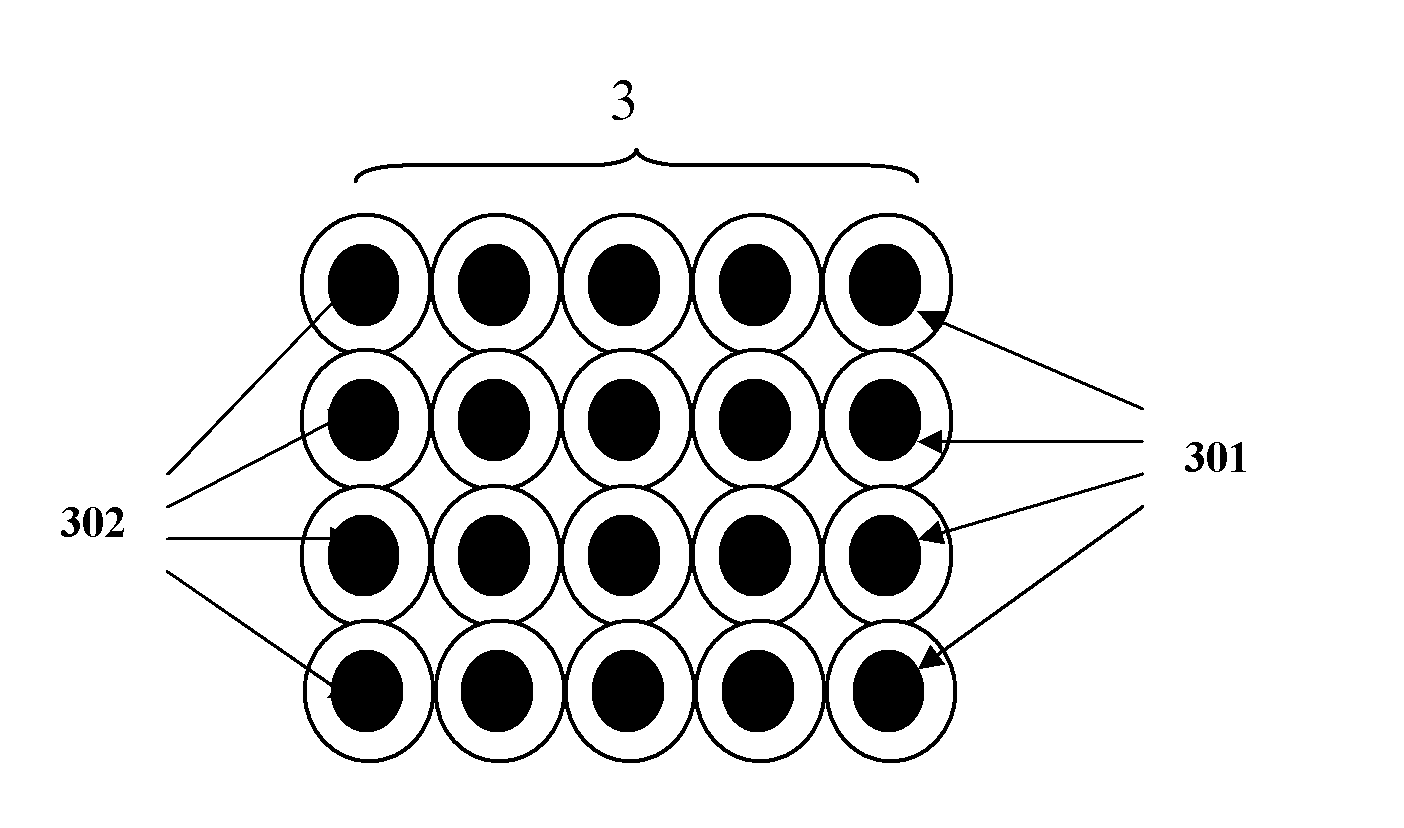

[0042] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-4 As shown, a nano-coaxial cable heterojunction array-based ultraviolet detector includes a substrate 1 and a conductive film 2, and the conductive film 2 is located on the substrate 1; the substrate 1 is a glass substrate 1 and a metal substrate 1 Or a silicon substrate 1, the conductive film 2 has NiO@TiO as an ultraviolet light absorbing layer 2 Nano coaxial cable heterojunction array 3 and at least one N-type ohmic electrode 5, said NiO@TiO 2 There is at least one P-type ohmic electrode 4 on the nano coaxial cable heterojunction array 3; the NiO@TiO 2 Nanocoax Heterojunction Array 3 TiO 2 Nanotube 301 arrays and filled with TiO 2 The NiO nanowire 302 in the nanotube 301 is composed of the TiO 2 The array of nanotubes 301 is made of TiO with a growth direction perpendicular to the conductive film 2 2 The nanotubes 301 are arranged in parallel, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com