Temperature control type heat conduction multifunctional cigarette microcapsule and preparation method thereof

A multi-functional, microcapsule technology, applied in the field of cigarettes, can solve the problems of poor heat transfer, weak taste, insufficient smoke volume, etc., and achieve the effects of preventing volatilization, enhancing sensory quality and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

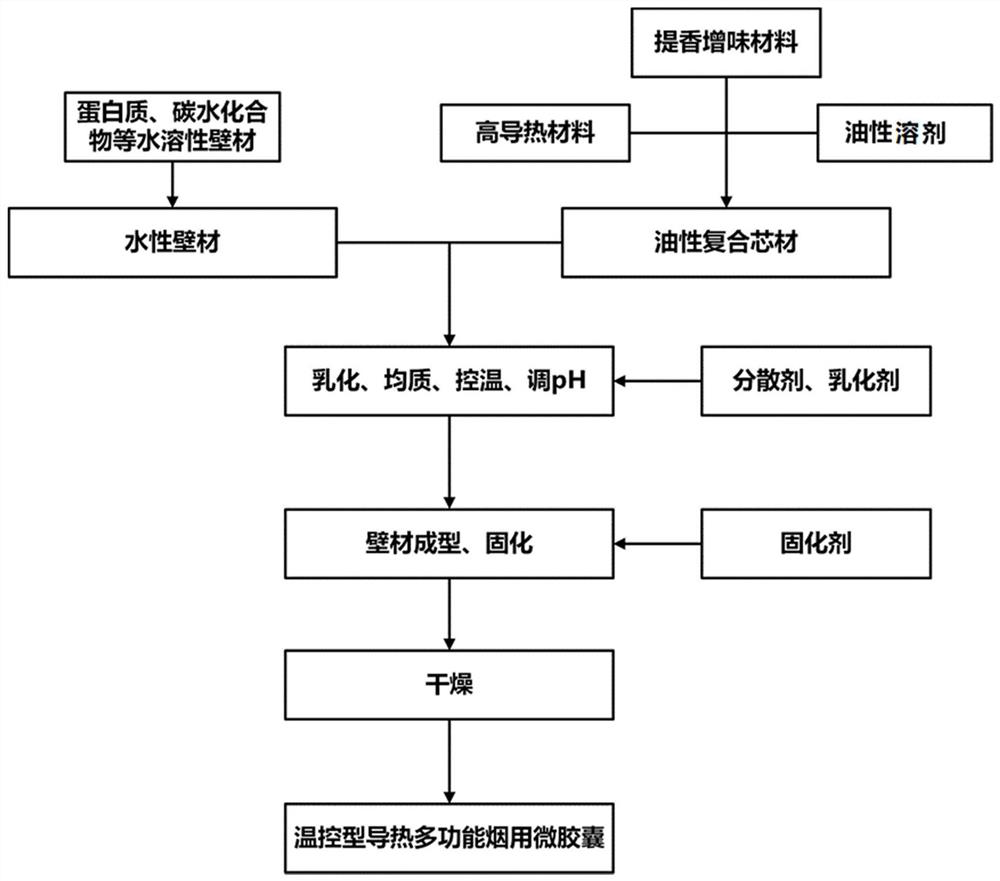

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing temperature-controlled heat-conducting multifunctional microcapsules for cigarettes, which includes the following steps:

[0033] (1) Add 2wt% type A gelatin and 2wt% gum arabic to water at 50°C, mechanically stir and mix evenly to obtain a wall material solution;

[0034] (2) Add high thermal conductivity graphite micropowder to caprylic acid glyceride, add mass ratio of 3:10, control temperature at 50°C, add 2wt% SDS as a dispersant, mix evenly, and use it as a mixed core material;

[0035] (3) Slowly add the mixed core material into the wall material solution at a mass ratio of 1:1, add 1wt% Tween 65, and emulsify and homogenize with a high-speed homogenizer at a shear rate of 10000r / min. The shearing time is 5min to form an O / W emulsion;

[0036] (4) Keep the stirring state of 600r / min, adjust the pH of the O / W type emulsion with 10% acetic acid to be 4.0, keep the temperature at 50°C, keep the constant temperature fo...

Embodiment 2

[0040] Such as figure 1 As shown, this embodiment provides a method for preparing temperature-controlled heat-conducting multifunctional microcapsules for cigarettes, which includes the following steps:

[0041] (1) Add 2wt% ordinary gelatin and 2wt% gum arabic to water at 50°C, mechanically stir and mix evenly to obtain a wall material solution;

[0042] (2) Add γ-caprolactone to the oily solvent decyl acetate as a taste-enhancing and flavor-enhancing substance, and add a mass ratio of 1:4 to obtain an oily mixed solvent after mixing evenly. Add graphene, and oily mixed solvent The mass ratio of adding is 1:10. The temperature is controlled at 50°C, and 1wt% sodium carboxymethylcellulose is added as a dispersant, mixed evenly, and used as a mixed core material;

[0043] (3) Slowly add the mixed core material into the wall material solution, the mass ratio is 1:1, add 1wt% Tween 85, emulsify and homogenize with a high-speed homogenizer, and the shear speed is 11000r / min , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com