Low chloride ion wet strength agent and preparation method thereof

A technology of chloride ion and wet strength agent, applied in the field of papermaking auxiliaries, can solve the problems of human toxicity, environmental harm, organic chlorine pollution, etc., and achieve the effects of low organic chlorine, easy operation control and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

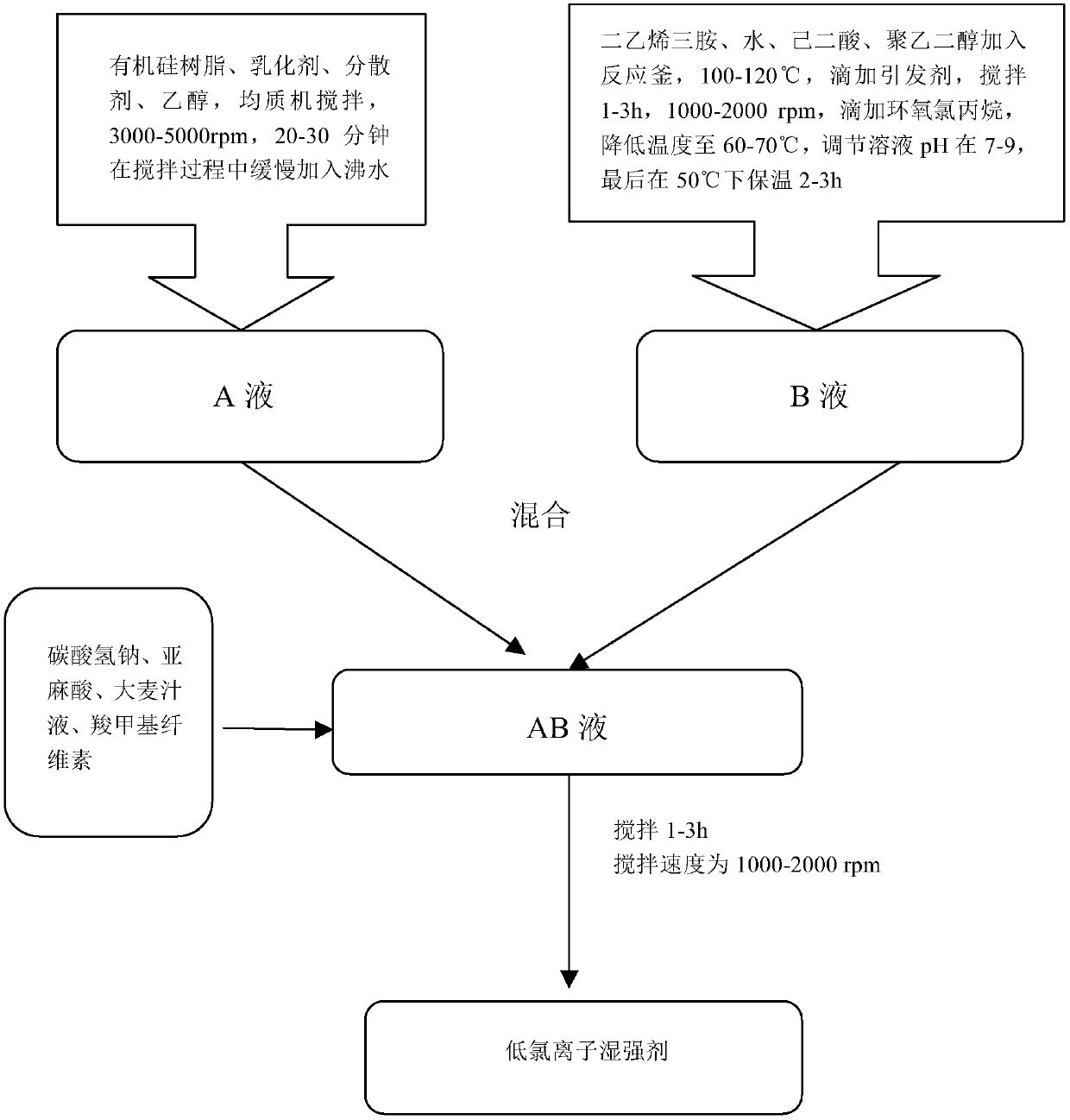

Method used

Image

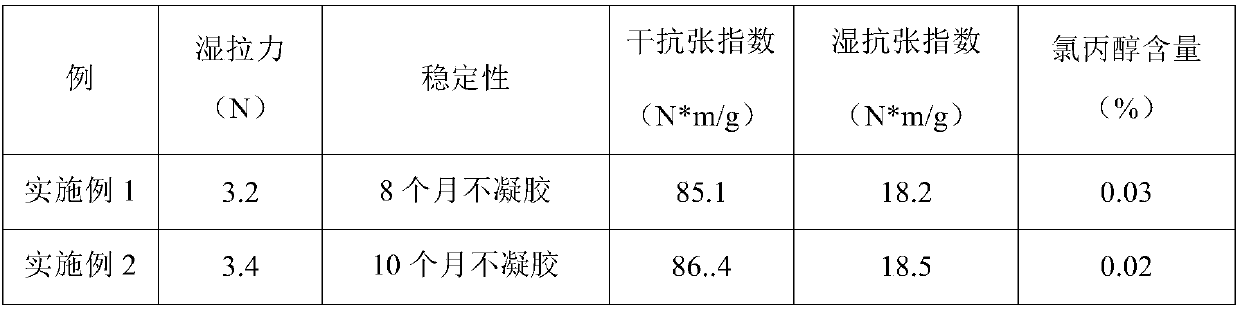

Examples

Embodiment 1

[0036] A preparation method of a low chloride ion wet strength agent, comprising:

[0037] (1) Preparation of liquid A

[0038] In a beaker, add 20 parts of silicone resin, 1 part of sucrose ester, 1 part of dispersant (sodium lauryl sulfate and triethanolamine according to the mass ratio of 1:1.3), 5 parts of absolute ethanol, stir with a homogenizer, 3000rpm , 20 minutes, slowly add 30 parts of boiling water during the stirring process to obtain liquid A;

[0039] (2) Preparation of liquid B

[0040] Add 10 parts of diethylenetriamine, 50 parts of water, 30 parts of adipic acid, and 1 part of polyethylene glycol into the reaction kettle, slowly raise the temperature to 100 ° C, and slowly add ammonium persulfate at a rate of 1 mL / min , fully stirred for 1 hour, and the stirring speed was 2000rpm, then slowly added 5 parts of epichlorohydrin dropwise, lowered the temperature to 60°C, added appropriate sodium bicarbonate, adjusted the pH of the solution to 7, and finally kep...

Embodiment 2

[0044] A preparation method of a low chloride ion wet strength agent, comprising:

[0045] (1) Preparation of liquid A

[0046] In a beaker, add 30 parts of silicone resin, 2 parts of sorbitol fat, 2 parts of dispersant (sodium lauryl sulfate and triethanolamine according to the mass ratio of 1:1.4), 8 parts of absolute ethanol, and stir with a homogenizer , 5000rpm, 30 minutes, slowly add 40 parts of boiling water during the stirring process, and A liquid can be obtained;

[0047] (2) Preparation of liquid B

[0048] Add 15 parts of diethylenetriamine, 80 parts of water, 35 parts of adipic acid, and 2 parts of polyethylene glycol into the reaction kettle, slowly raise the temperature to 110°C, and slowly add potassium persulfate at a rate of 1 mL / min Stir fully for 2 hours at a stirring speed of 2000rpm, then slowly add 8 parts of epichlorohydrin dropwise, lower the temperature to 70°C, add appropriate sodium carbonate, adjust the pH of the solution to 8, and finally keep w...

Embodiment 3

[0052] A preparation method of a low chloride ion wet strength agent, comprising:

[0053] (1) Preparation of liquid A

[0054] In a beaker, add 40 parts of silicone resin, 3 parts of soybean lecithin, 3 parts of dispersant (sodium lauryl sulfate and triethanolamine according to the mass ratio of 1:1.5), 10 parts of ethanol, stir with a homogenizer, 5000rpm, 20 Minutes, slowly add 50 parts of boiling water during the stirring process to obtain liquid A;

[0055] (2) Preparation of liquid B

[0056] Add 20 parts of diethylenetriamine, 100 parts of water, 40 parts of adipic acid, and 3 parts of polyethylene glycol into the reactor, slowly raise the temperature to 120°C, and slowly add potassium persulfate at a rate of 2 mL / min , fully stirred for 3 hours at a stirring speed of 2000rpm, then slowly added 10 parts of epichlorohydrin dropwise, lowered the temperature to 70°C, added appropriate sodium bicarbonate, adjusted the pH of the solution to 8, and finally kept it at 50°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com