Preparation method for epoxy anticorrosive coating

A technology of anti-corrosion coating and epoxy, which is applied in the preparation of epoxy anti-corrosion coating and the preparation field of epoxy anti-corrosion coating modified by soluble polyoxyethylene thiophene, which can solve the problem of weak anti-corrosion performance of materials and complex process , unfriendly environment and other issues, to achieve the effect of low cost, reasonable preparation route, high promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

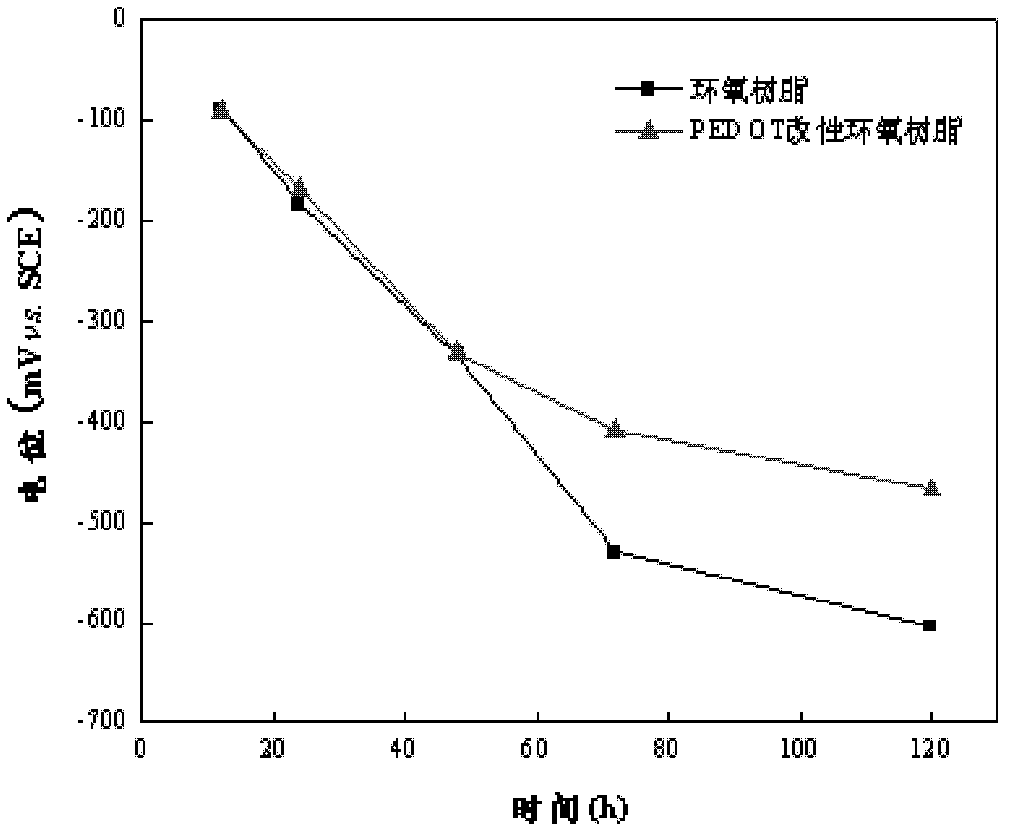

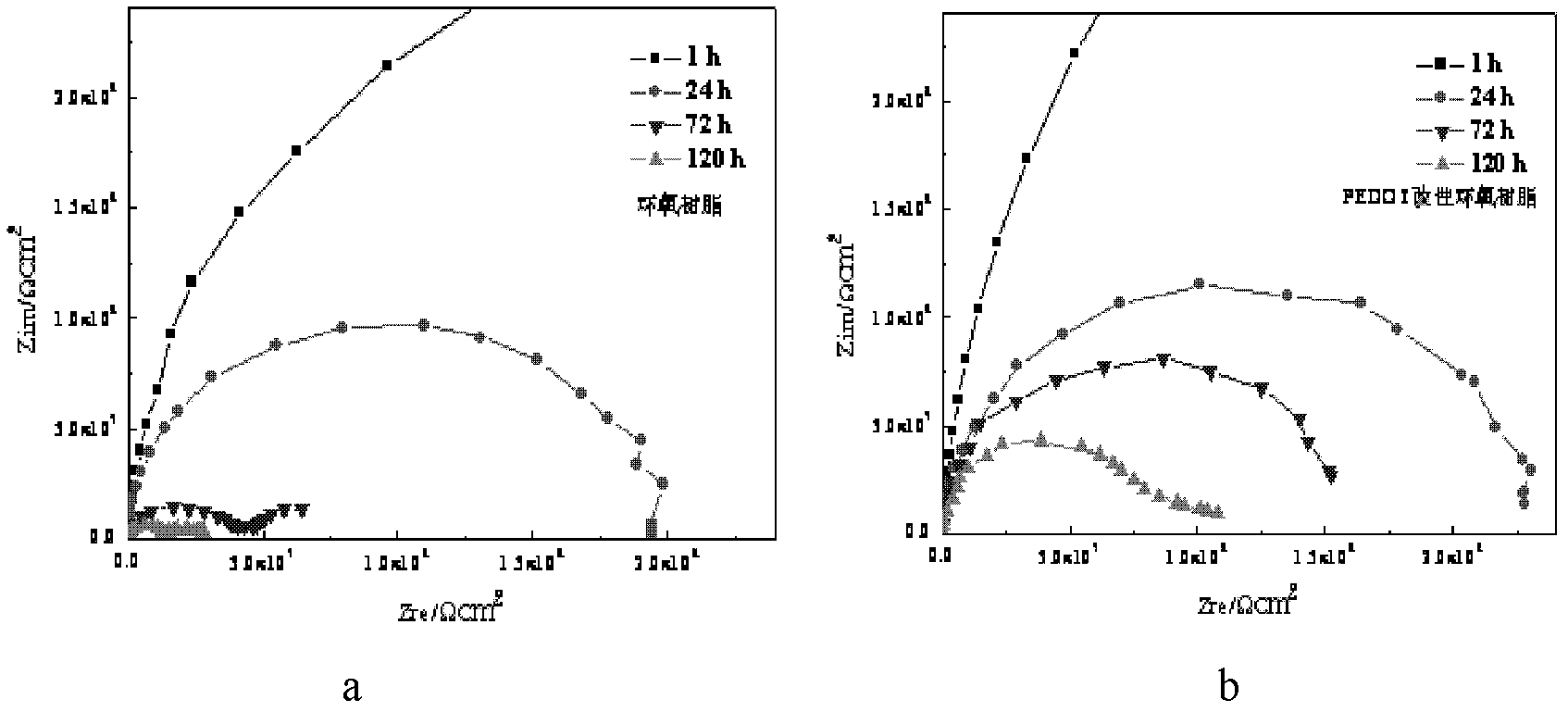

[0022] Dissolve 0.05mol dioxyethylenethiophene monomer and 0.02mol sodium dodecylbenzenesulfonate in 500mL distilled water, place in an ice-water bath and stir for 2 hours, dissolve 0.02mol ammonium persulfate in 200mL distilled water and place on ice Stir in a water bath for 0.5 hours, add the ammonium persulfate solution dropwise into the dioxyethylene thiophene monomer suspension, stir for 24 hours, add acetone and filter, wash the product repeatedly with acetone and distilled water, and dry it in vacuum at 60°C After 24 hours, polyoxyethylene thiophene solid powder was obtained; then 10 g of epoxy resin, 10 g of polyamide, and 0.06 g of polyoxyethylene thiophene solid powder were placed in a container, stirred and ultrasonicated for 1 hour, and then sprayed or brushed on On the steel plate, put the steel plate in an environment of 20°C and cure for about 15 hours to obtain a coating material; as a comparison, prepare, coat and cure 10g of epoxy resin and 10g of polyamide in...

Embodiment 2

[0024] Dissolve 0.075mol dioxyethylenethiophene monomer and 0.03mol cetyltrimethylammonium bromide in 500mL distilled water, place in an ice-water bath and stir for 2 hours, dissolve 0.06mol ferric chloride in 200mL distilled water Place in an ice-water bath and stir for 0.5 hours, add the ferric chloride solution dropwise into the dioxyethylene thiophene monomer suspension, stir for 24 hours, add acetone and filter, and the obtained product is washed repeatedly with acetone and distilled water, and placed in Vacuum dry at 60°C for 24 hours to obtain polyoxyethylene thiophene solid powder; then put 10g of epoxy resin, 15g of ethylenediamine, and 0.015g of polyoxyethylene thiophene solid powder in a container, stir and sonicate for 0.5h, Then it is scraped and coated on the steel plate; the steel plate is placed in the environment of 20 ℃ and cured for about 20 hours to obtain the coating material; as a comparison, 10g of epoxy resin and 15g of trimethylhexamethylenediamine are ...

Embodiment 3

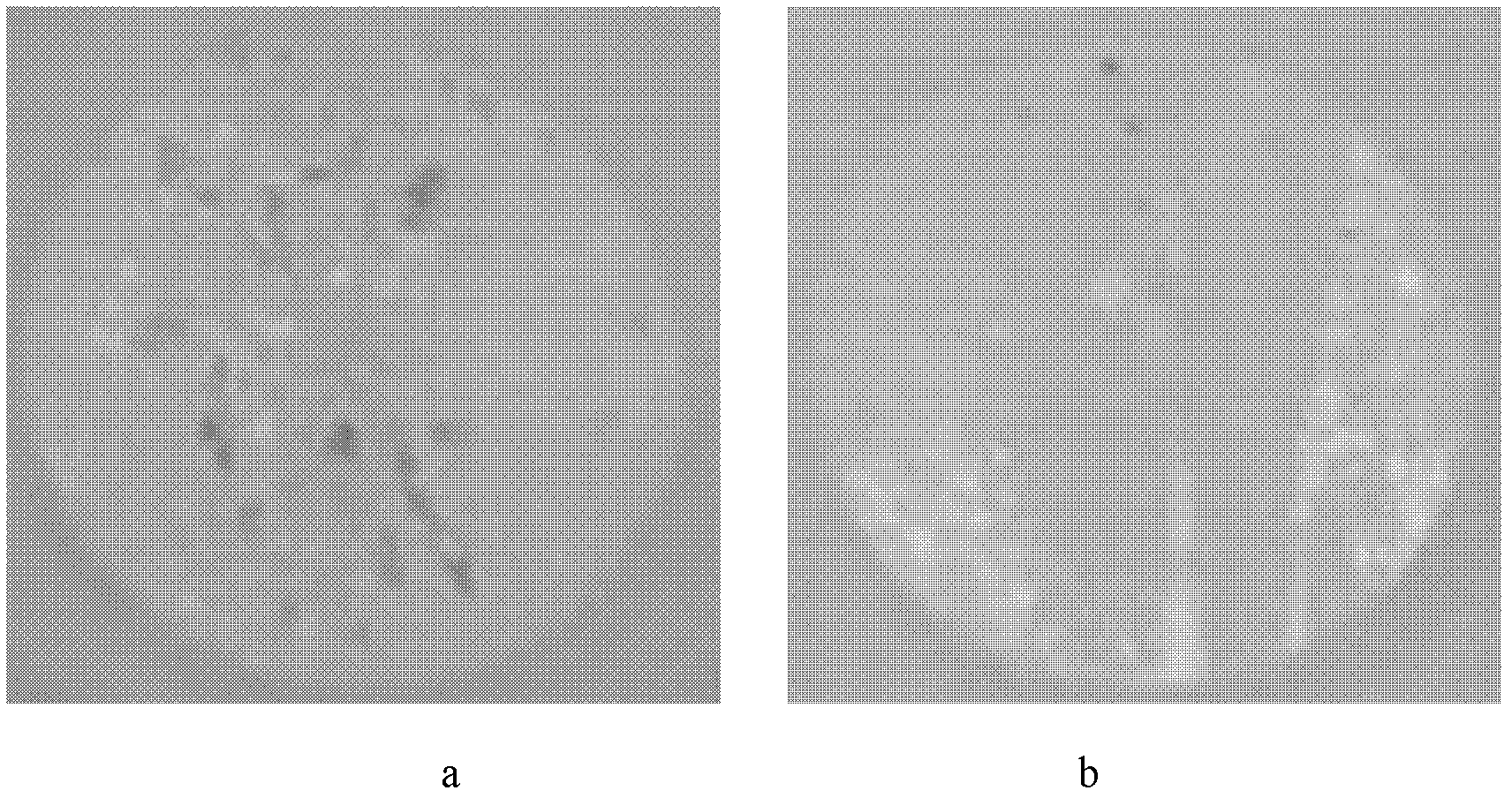

[0026]Dissolve 0.02mol dioxyethylene thiophene monomer and 0.01mol sodium lauryl sulfate in 500mL distilled water, place in an ice-water bath and stir for 2 hours, dissolve 0.01mol potassium permanganate in 200mL distilled water and place in an ice-water bath Stir in the middle for 0.5 hours, add the potassium permanganate solution dropwise into the dioxyethylene thiophene monomer suspension, stir for 24 hours, add acetone and filter, and the obtained product is washed repeatedly with acetone and distilled water, and vacuum-dried at 60°C After 24 hours, polyoxyethylene thiophene solid powder was obtained; then 10 g of epoxy resin, 15 g of trimethylhexamethylenediamine, and 0.045 g of polyoxyethylene thiophene solid powder were placed in a container, stirred and ultrasonically 0.5 h, and then spray, scrape or brush on the steel plate; put the steel plate in an environment of 25 ° C for about 15 hours to obtain the coating material; Figure 5 The scanning electron microscope pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com