Ultraviolet sensor with nanometer TiO-M thin film and production thereof

An ultraviolet light and sensor technology, applied in the field of optoelectronics, can solve the problems of high cost, low detector sensitivity, and immature preparation technology, and achieve the effects of low price, high sensitivity, and simple and mature preparation technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Proportion: tetrabutyl titanate: absolute ethanol: deionized water: diethanolamine = 20:100:1:6 volume ratio

[0034] Tetrabutyl titanate is used as the precursor. Tetrabutyl titanate and diethanolamine were dissolved in absolute ethanol (60% of the total amount), and stirred for 60 minutes to obtain a mixed solution. In addition, after mixing deionized water and absolute ethanol (accounting for 40% of the total amount) evenly, dropwise dropwise into the above-mentioned mixed solution under continuous stirring, and continue stirring for 60 minutes after the dropwise addition, to obtain a uniform, transparent light yellow TiO 2Sol.

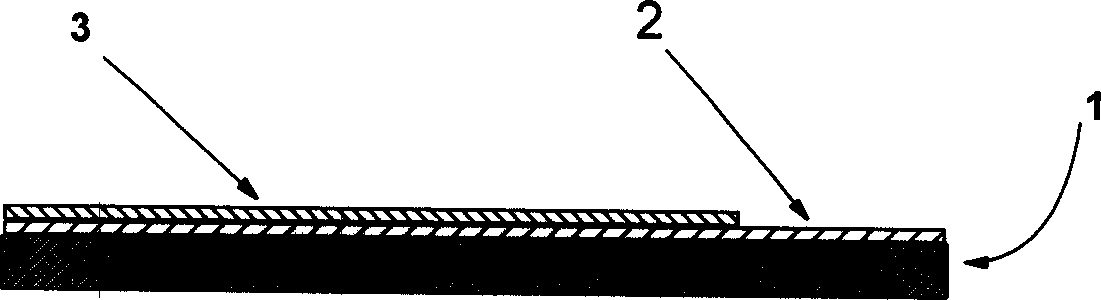

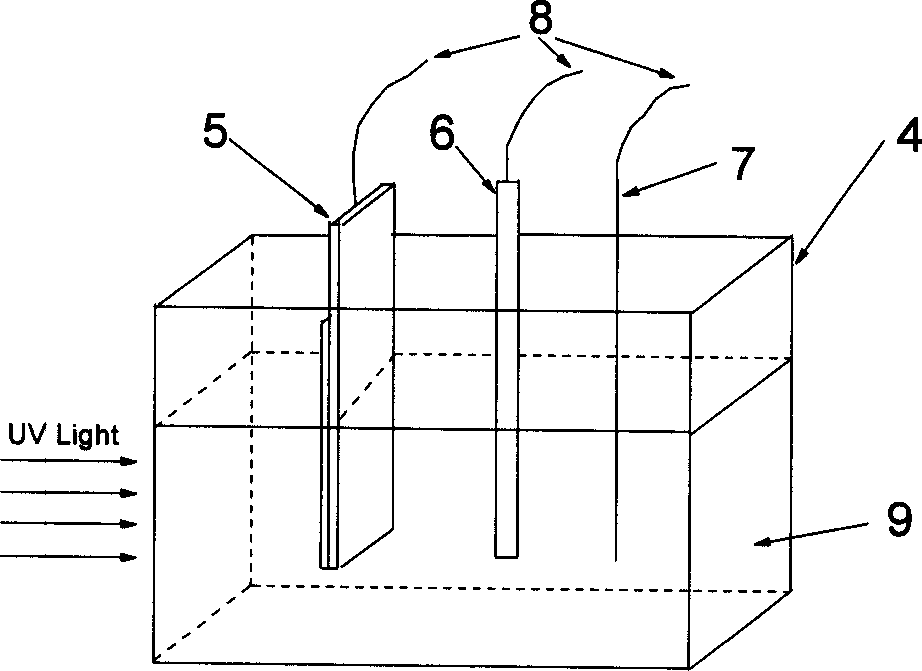

[0035] Nano-TiO 2 Preparation of thin-film photosensitive electrode 5: take clean conductive glass as a substrate, and use a self-made film pulling machine (speed precision 10 μm / s) to form a film by dipping-pulling method. After each film drawing, put the substrate into an oven at a temperature of 80-120°C to dry for 10-20 minutes, whic...

Embodiment 2

[0042] Proportion: tetrabutyl titanate: absolute ethanol: deionized water: diethanolamine: zinc nitrate = 20: 100: 1: 6: m (m = 0.0448g)

[0043] 0.0448gZn(NO 3 ) 2 Dissolve in 30ml of absolute ethanol, then add 10ml of tetrabutyl titanate and 3ml of diethanolamine, and stir for 60min to obtain a mixed solution. In addition, mix 0.5ml of deionized water and 10ml of absolute ethanol evenly, dropwise into the above mixture under continuous stirring, and continue to stir for 60min after the addition, to obtain a uniform and transparent TiO 2 : Zn sol.

[0044] The preparation of the thin-film electrode and the ultraviolet photochemical cell and the assembly of the ultraviolet light sensor device are the same as in Example 1.

[0045] Figure 8 TiO prepared under the same conditions 2 The X-ray diffraction analysis results of the powder crystal sample obtained by roasting the sol at 450°C. The grain size is about 15nm, which is anatase phase. In this example, changing Zn 2...

Embodiment 3

[0049] Proportion: tetrabutyl titanate: absolute ethanol: deionized water: diethanolamine: polyethylene glycol 2000=20:100:1:6:m (m=1.0g)

[0050] Tetrabutyl titanate and diethanolamine were dissolved in absolute ethanol (60% of the total amount), and stirred for 60 minutes to obtain a mixed solution. In addition, after mixing deionized water and absolute ethanol (accounting for 40% of the total amount) evenly, it was dripped into the above-mentioned mixed solution drop by drop under continuous stirring, and 1.0 g of polyethylene glycol 2000 was added to the solution after the dropwise addition. Continue stirring for 60min to obtain uniform, transparent light yellow TiO 2 Sol.

[0051] The preparation of the thin-film electrode and the ultraviolet photochemical cell and the assembly of the ultraviolet light sensor device are the same as in Example 1.

[0052] Figure 11 Transient photocurrent spectra of samples obtained in this example at different potentials. In this expe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com