Carbon-based electrode material having super high specific capacitance and combined electrode material thereof

An electrode material, specific capacitance technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of poor stability, low power density, and can not fully display the energy storage characteristics of super electrode materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

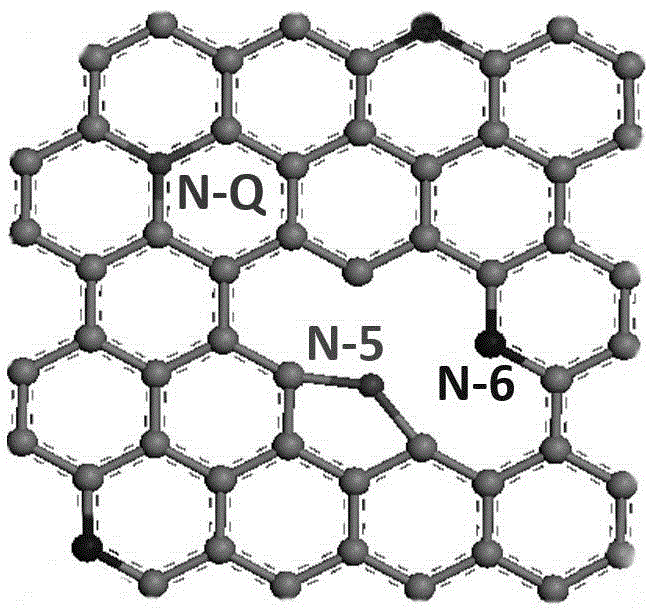

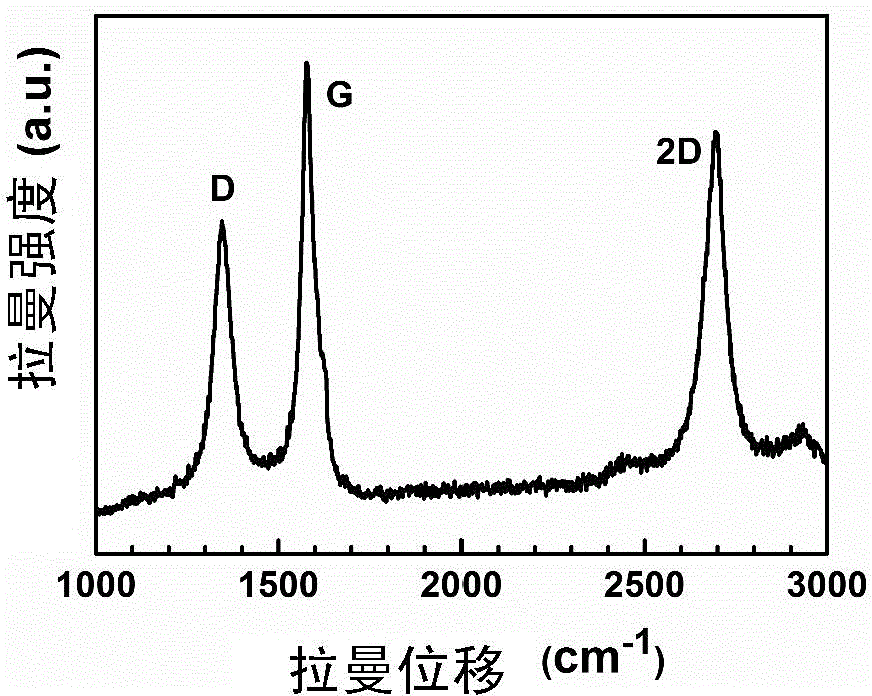

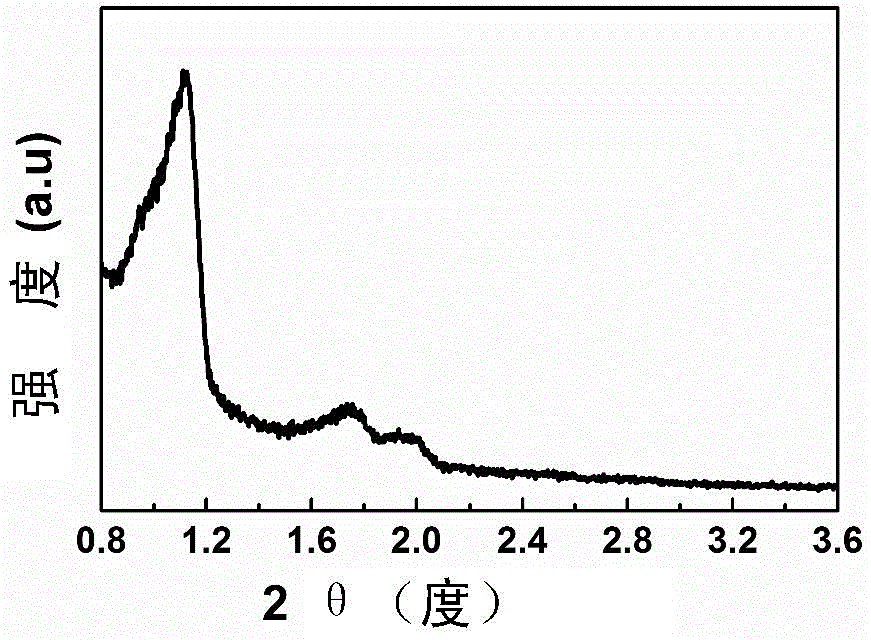

[0114] Example 1 Mesoporous nitrogen-doped carbon-based material

[0115] Prepare an aqueous solution of nickel nitrate with a concentration of 0.1mol / L, and mix it with commercial mesoporous silica SBA-15 at a mass ratio of nickel to silica of 1:2. Stir, ultrasonically disperse, vacuumize to a pressure of 20Pa, and form a sol after the solution evaporates. In an argon atmosphere containing 5% hydrogen, the temperature was raised to 450° C. and kept for 2 hours to obtain mesoporous silica (SBA-15 / Ni) filled with metallic nickel;

[0116] Dissolve carbon source polyfurfuryl alcohol and aminoguanidine in ethanol at a ratio of 5:1, add SBA-15 / Ni, disperse ultrasonically for 30 minutes, and dry at 100°C for 10 hours to obtain SBA-15 / Ni / polyfurfuryl alcohol / aminoguanidine dry gel;

[0117] Place 50 grams of the above sample in an atmosphere furnace, raise the temperature to 900°C in argon or nitrogen, feed hydrogen, ammonia and methane at a ratio of 20:15:10sccm, and keep warm fo...

Embodiment 2

[0136] Example 2 Mesoporous nitrogen-doped graphene with different redox potentials

[0137] Obtaining the preparation method of the mesoporous silica (SBA-15 / Ni) filled with metallic nickel is exactly the same as that of Example 1;

[0138] Take the carbon source polyfurfuryl alcohol and aminoguanidine according to the ratio of 5:1 (i.e. Example 1), 2:1, and 1:1 respectively dissolved in ethanol, add SBA-15 / Ni, ultrasonically disperse for 30 minutes, at 100 ℃ After drying for 10 hours, three groups of xerogels of SBA-15 / Ni / polyfurfuryl alcohol / aminoguanidine were obtained;

[0139] Take 50 grams of each of the above samples and place them in an atmosphere furnace, raise the temperature to 900°C in argon or nitrogen, feed hydrogen, ammonia and methane at a ratio of 20:15:10sccm, and keep warm for 10-30 minutes. Cool to room temperature, take out the sample;

[0140] Soak the sample obtained above in a mixed solution of hydrochloric acid and hydrofluoric acid, and after 24 ho...

Embodiment 3

[0145] Example 3 Mesoporous boron-doped carbon-based material

[0146] The preparation of mesoporous silica (SBA-15 / Ni) filled with metallic nickel is the same as in Example 1;

[0147] Take carbon source polyfurfuryl alcohol (PFA) and boron tribromide (BBr 3 ) was dissolved in ethanol at a ratio of 5:2, SBA-15 / Ni was added, ultrasonically dispersed for 30 minutes, and dried at 100°C for 10 hours to obtain SBA-15 / Ni / PFA / BBr 3 dry gel;

[0148] Place 50 grams of the above sample in an atmosphere furnace, raise the temperature to 800°C in argon or nitrogen, feed hydrogen and methane at a ratio of 20:10sccm, and keep warm for 10-30 minutes. Cool to room temperature, take out the sample;

[0149] Soak the sample obtained above in a mixed solution of hydrochloric acid and hydrofluoric acid, and after 24 hours, filter and wash with a large amount of deionized water and ethanol. Gained boron-doped mesoporous doped graphene after drying;

[0150] The characterization and electroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Volume specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com