Carbon nanotube/graphene composite gel and preparation method thereof

A graphene composite and carbon nanotube technology, which can be used in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc. Avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

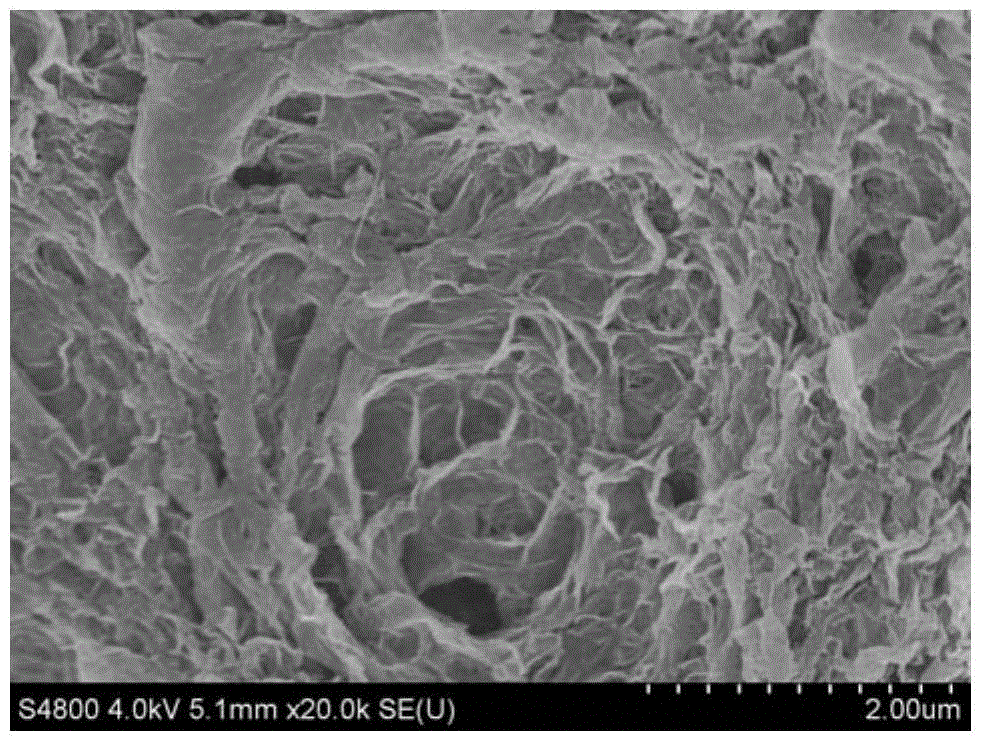

[0027] This embodiment provides a carbon nanotube / graphene composite gel, which has a three-dimensional porous structure, in which single-walled carbon nanotubes are interspersed in the graphene gel.

[0028] The preparation method of the carbon nanotube / graphene composite gel is as follows:

[0029] (1) Take natural graphite of 10000 mesh as raw material, adopt Hummers-Offeman method to prepare graphite oxide; then formulate the obtained graphite oxide into 4mg / ml aqueous solution, and then use ultrasonic cleaning machine to ultrasonic treatment for 3h to obtain graphene oxide aqueous solution;

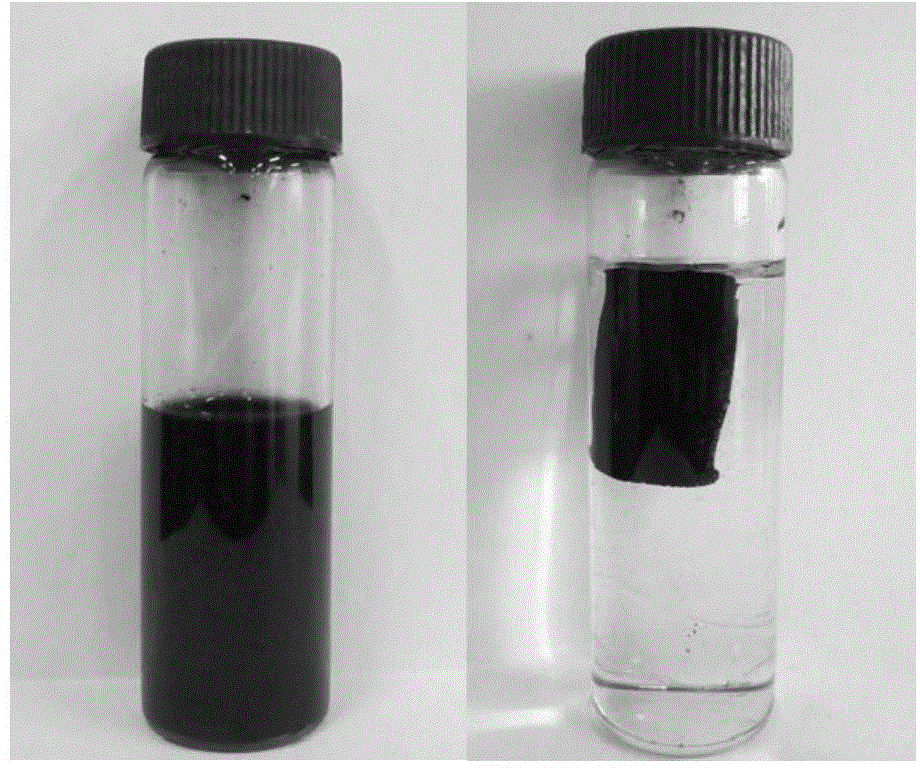

[0030] (2) Take 15ml of the above graphene oxide solution into a sample bottle, then add 3mg of single-arm carbon nanotubes, and ultrasonicate for 2h to obtain a uniform dispersion of carbon nanotubes / graphene oxide, such as figure 1 As shown in the picture on the left;

[0031] (3) Transfer the sample bottle to the reaction kettle, place the reaction kettle in a constant temperature oven at ...

Embodiment 2

[0034] This embodiment provides a carbon nanotube / graphene composite gel, which has a three-dimensional porous structure, in which single-walled carbon nanotubes are interspersed in the graphene gel.

[0035] The preparation method of the carbon nanotube / graphene composite gel is as follows:

[0036] (1) The steps of (1) in Example 1 are exactly the same;

[0037] (2) Take 15ml of the above graphene oxide solution in a sample bottle, then add 30mg of single-arm carbon nanotubes, and ultrasonicate for 2h to obtain a uniform carbon nanotube / graphene oxide dispersion;

[0038] (3) Transfer the sample bottle to the reaction kettle, place the reaction kettle in a constant temperature oven at 180°C for 12 hours, and then naturally cool to room temperature to obtain a carbon nanotube / graphene composite gel, which is taken out for washing and placed in the container Obtain an aqueous solution of carbon nanotube / graphene composite gel in a sample bottle with an aqueous solution;

[0039] (4) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com