Linear secure high-energy-density supercapacitor and preparation method thereof

A supercapacitor, high energy density technology, applied in liquid electrolytic capacitors and other directions, can solve the problem of short circuit of linear capacitor electrodes, and achieve the effect of easy purchase, high capacitance and energy density, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

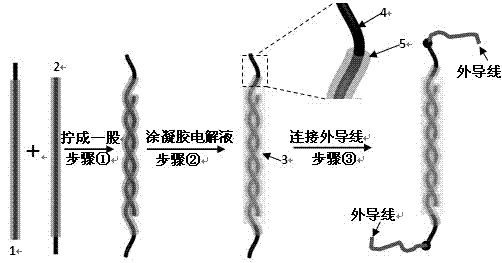

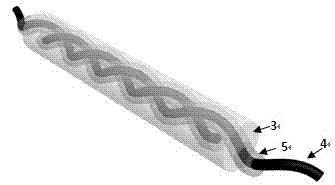

[0025] The preparation method of the safe high energy density supercapacitor of linear comprises the following steps:

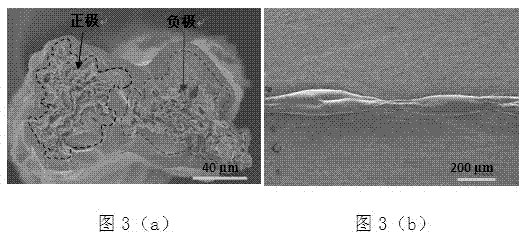

[0026] 1) Conductive fiber with core-shell structure obtained by coaxial wet spinning method, the inner core of the conductive fiber with core-shell structure is conductive carbon nanomaterial 4, the outer shell is polymer 5, two core-shell structures The conductive fibers are respectively used as the positive electrode 1 and the negative electrode 2 of the linear supercapacitor, and are wound together to make the positive and negative electrodes twisted into one strand;

[0027] 2) Soak the twisted positive and negative electrodes in the gel electrolyte, or drop the gel electrolyte onto the surface of the twisted positive and negative electrodes, or pass the twisted positive and negative electrodes through gel electrolysis The small holes of the liquid, so that the gel electrolyte is coated on the surface of the positive and negative electrodes, and solidifi...

Embodiment 1

[0033] 1) Conductive fiber with core-shell structure obtained by coaxial wet spinning method. The inner core of the conductive fiber with core-shell structure is graphene, and the outer shell is sodium carboxymethyl cellulose. Two core-shell structures The conductive fibers are respectively used as the positive electrode 1 and the negative electrode 2 of the linear supercapacitor, and are wound together to make the positive and negative electrodes twisted into one strand;

[0034] 2) Soak the twisted positive and negative electrodes in a solution of sulfuric acid / polyvinyl alcohol / water (weight ratio 1:1:10), and drop them on the surface of the twisted positive and negative electrodes, so that the gel electrolyte is coated Cover the surface of the positive and negative electrodes, and solidify at 25 to form a gel electrolyte gel layer 3;

[0035] 3) Connect the twisted positive and negative electrodes coated with the gel layer 3 to the wires respectively through conductive sil...

Embodiment 2

[0038] 1) Conductive fiber with core-shell structure obtained by coaxial wet spinning method, the inner core of the conductive fiber with core-shell structure is carbon nanotube, the outer shell is sodium carboxymethyl cellulose, two core-shell The conductive fibers of the structure are respectively used as the positive electrode 1 and the negative electrode 2 of the linear supercapacitor, and are wound together to make the positive and negative electrodes twisted together;

[0039] 2) Add the solution of sulfuric acid / polyvinyl alcohol / water (weight ratio 1:1:10) dropwise to the surface of the positive and negative electrodes twisted together so that the gel electrolyte is coated on the surface of the positive and negative electrodes. solidified to form a gel electrolyte gel layer 3;

[0040] 3) Connect the twisted positive and negative electrodes coated with the gel layer 3 to the wires respectively through conductive silver glue.

[0041] After the above steps, the obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com