Single-phase CuO nanosheet array film and preparation method thereof

A nanosheet array, nanosheet technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of unsatisfactory cycle stability of electrode materials, insufficient conversion to CuO, and complex process. and other problems, to achieve the effect of excellent visible light absorption characteristics, simple and easy method, stable and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

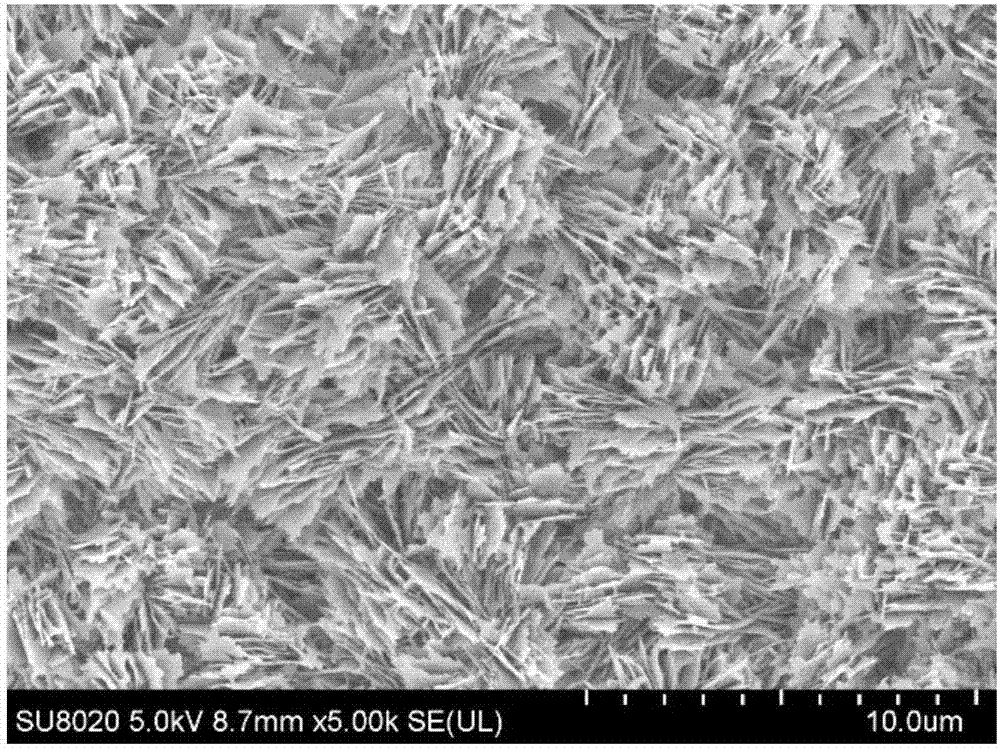

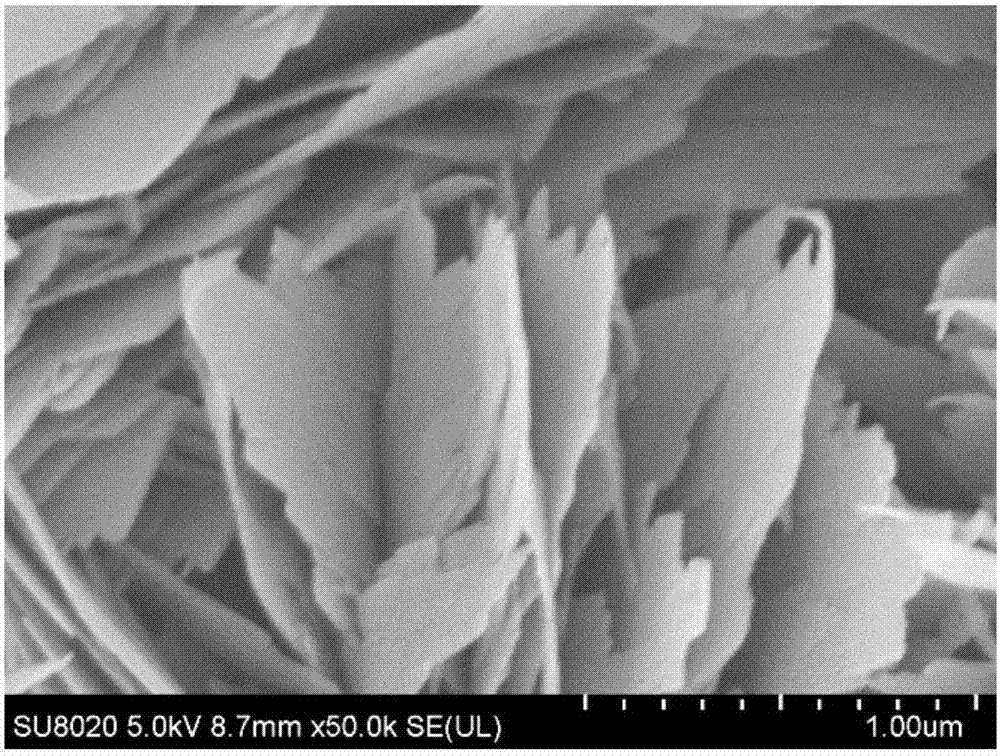

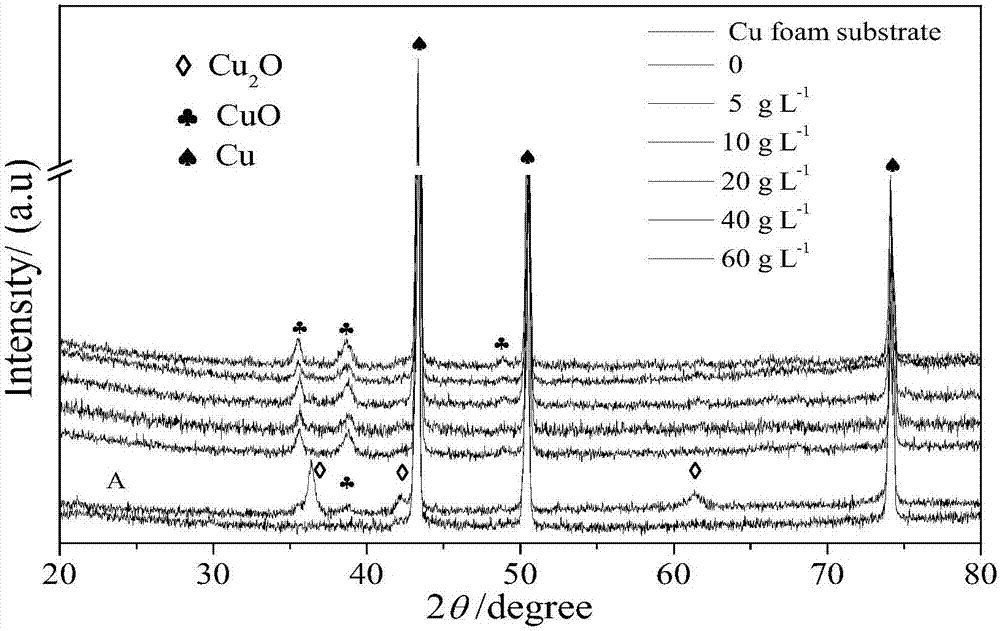

[0028] One-step method for preparing single-phase CuO nanosheet array film, the specific steps are as follows

[0029] (1) Pretreatment of high-purity copper mesh:

[0030] After cleaning the high-purity copper mesh repeatedly with alcohol and distilled water, soak it in RY-522 copper chemical polishing solution at room temperature for 30s, then take it out and wash it with distilled water, then neutralize it with 10g / L NaOH, clean it with distilled water ultrasonically and install it directly Hang into the slot.

[0031] (2) Preparation of CuO nanosheet array thin film by galvanostatic anodic oxidation method

[0032] Using 40g / L sodium hydroxide, 150g / L sodium chloride, 1g / L polyethylene glycol 20000, 20g / L (NH 4 ) 6 Mo 7 o 24 4H 2 The mixed solution of O is used as the electrolyte, the high-purity copper mesh after pretreatment is used as the anode, and the high-purity titanium sheet is used as the cathode (wherein, the effective area of the high-purity titanium she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com