Nitrogen-cobalt-doped hollow carbon nanofiber, preparation method and application thereof and metal-air battery

A metal-air battery and carbon nanofiber technology, applied in battery electrodes, fiber processing, fuel cell-type half-cells and primary battery-type half-cells, etc., can solve the application limitations of zinc-air batteries, limit the wide range of applications, and reserve Scarcity and other issues, to achieve excellent electrochemical performance, good internal channels, improve electrochemical performance and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

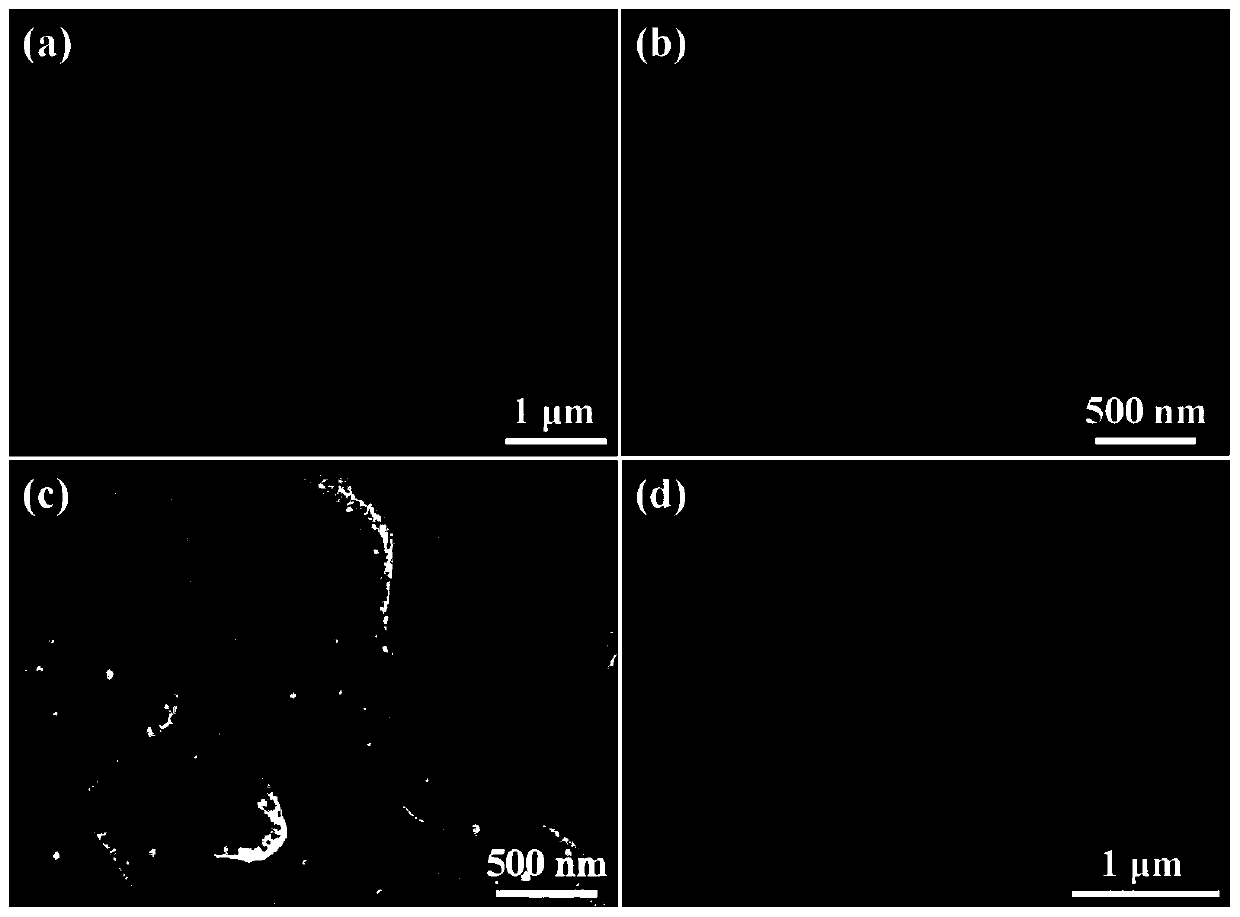

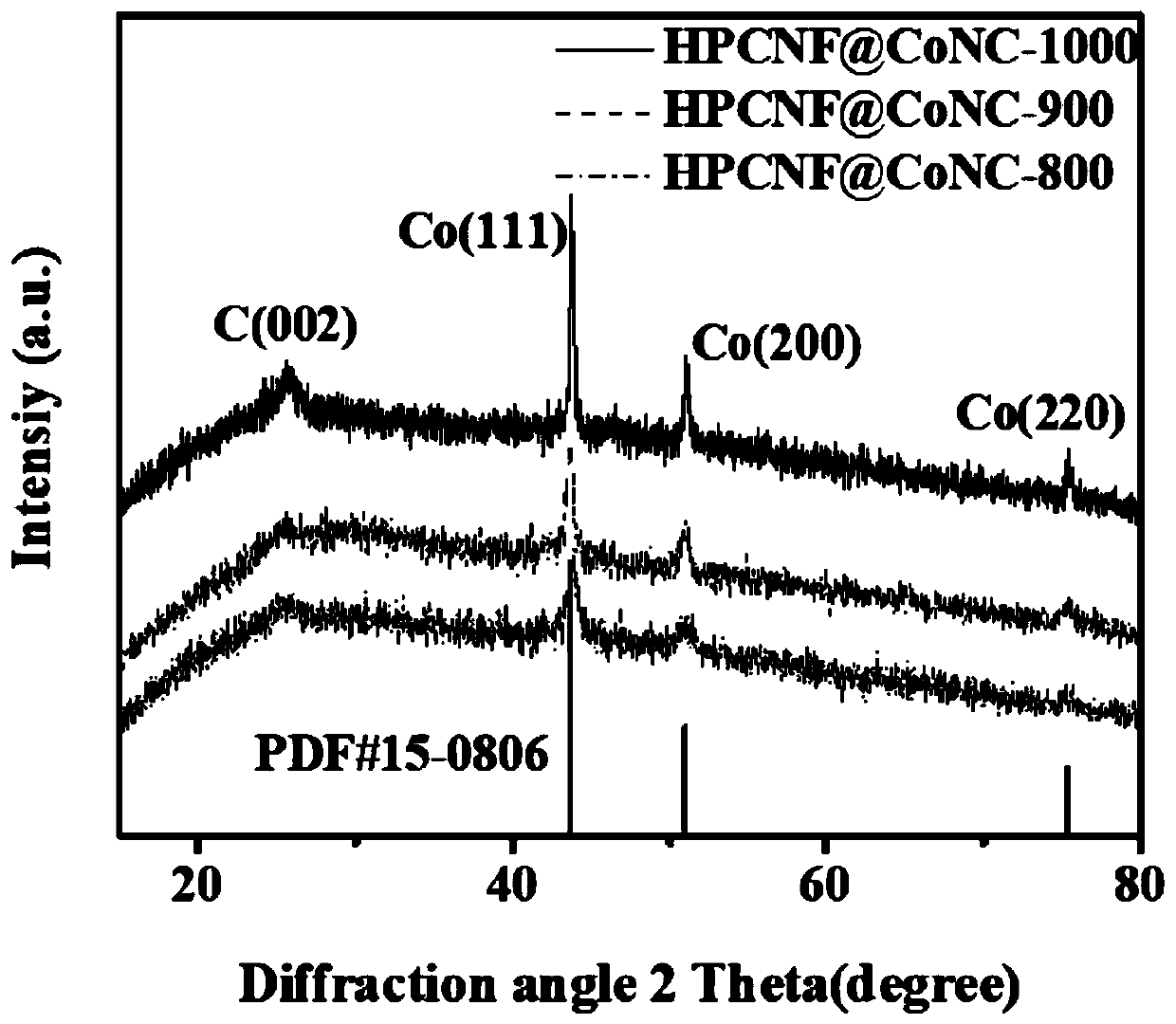

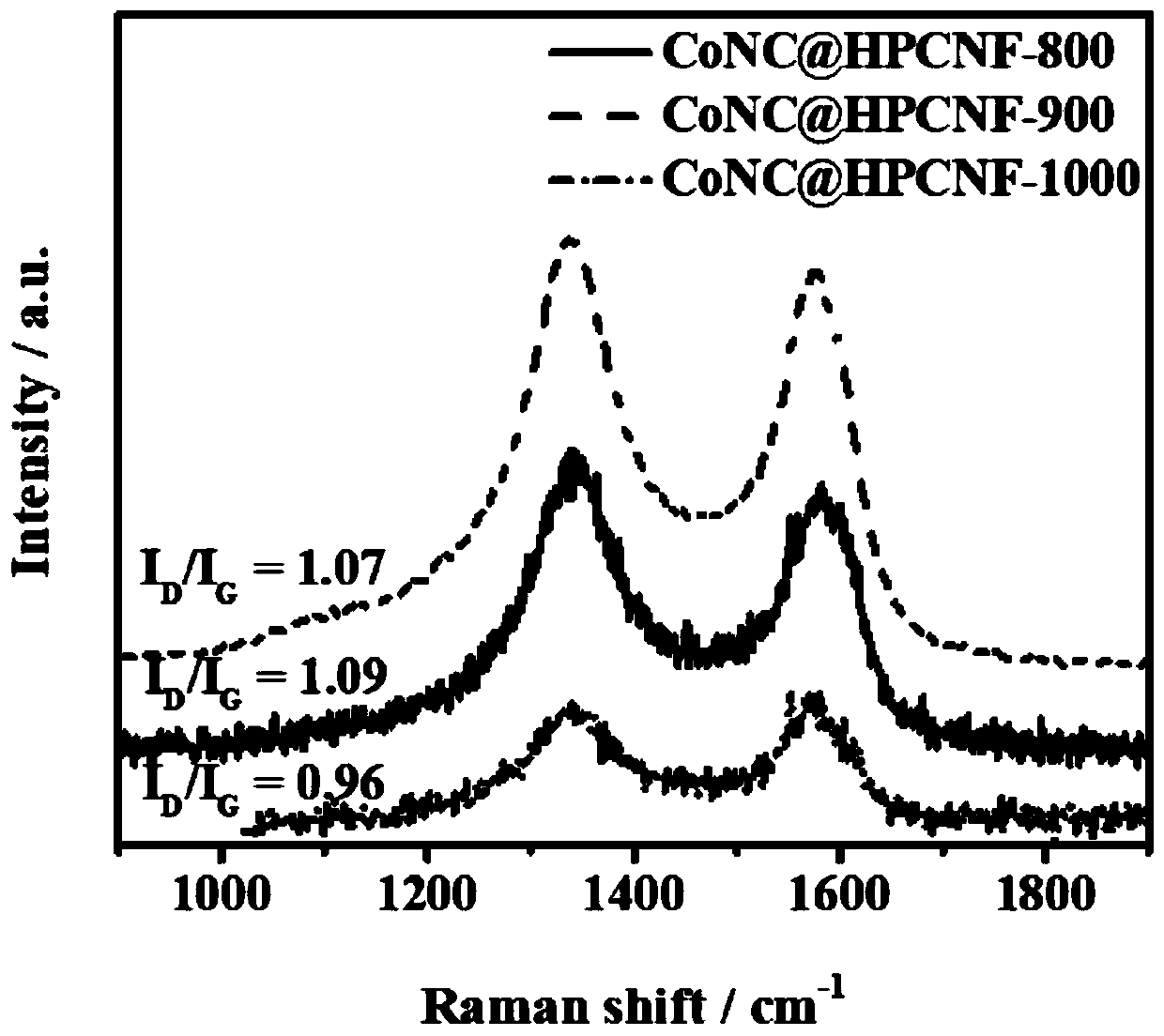

Image

Examples

preparation example Construction

[0032] The present invention also provides a method for preparing nitrogen-cobalt-doped hollow carbon nanofibers described in the above technical solution, comprising the following steps:

[0033] (1) Polymethyl methacrylate solution is used as the electrospinning inner layer solution; the mixed solution of polyacrylonitrile, cobalt acetate, polyvinylpyrrolidone and organic solvent is used as the electrospinning outer layer solution;

[0034] (2) subjecting the electrospinning inner layer solution and the electrospinning outer layer solution to coaxial electrospinning to form a fiber film on the receiving plate;

[0035] (3) leave standstill after mixing 2-methylimidazole, cobalt nitrate, fiber membrane and organic solvent, grow ZIF-67 crystal on the fiber membrane surface;

[0036] (4) The fiber membrane grown with ZIF-67 crystals was pre-oxidized and carbonized sequentially to obtain nitrogen-cobalt-doped hollow carbon nanofibers.

[0037] In the invention, the polymethyl m...

Embodiment 1

[0054] (1) Dissolve 2.2g polymethyl methacrylate (PMMA) into 8mL N,N-dimethylformamide (DMF) as the inner layer solution for electrospinning; 1.05g polyacrylonitrile (PAN), 0.315g cobalt acetate (Co(Ac) 2 ) and 0.6g polyvinylpyrrolidone (PVP) were dissolved in 9mL N,N-dimethylformamide (DMF) as the electrospinning outer layer solution, and the above inner layer and outer layer solutions were stirred at room temperature for 12h until The solute is completely dissolved.

[0055] (2) Pour the above-mentioned inner layer and outer layer electrospinning solution stirred at room temperature for 12 hours into a disposable syringe with a capacity of 10 mL, and place it in a propulsion pump. The aluminum foil was used as the receiver, and the voltage was set to 21kV; the temperature was maintained at 20°C; the humidity was maintained at 30%; the needle used was a coaxial electrospinning needle, and the inner and outer diameters were 0.86 and 1.66mm respectively; between the needle and...

Embodiment 2

[0060] (1) Dissolve 2.2g polymethyl methacrylate (PMMA) into 8mL N,N-dimethylformamide (DMF) as the inner layer solution for electrospinning; 1.05g polyacrylonitrile (PAN), 0.315g cobalt acetate (Co(Ac) 2 ) and 0.6g polyvinylpyrrolidone (PVP) were dissolved in 9mL N,N-dimethylformamide (DMF) as an electrospinning outer layer solution, and the above inner layer and outer layer solutions were stirred at room temperature for 12h until The solute is completely dissolved.

[0061] (2) Pour the above-mentioned inner layer and outer layer electrospinning solution into a disposable syringe with a capacity of 10mL, and place it in the propulsion pump. During the electrospinning process, use the aluminum foil fixed on the receiving plate as the receiver , the voltage was set to 21kV; the temperature was maintained at 20°C; the humidity was maintained at 30%; the needle used was a coaxial electrospinning needle with an inner diameter and an outer diameter of 0.86 and 1.66mm respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com